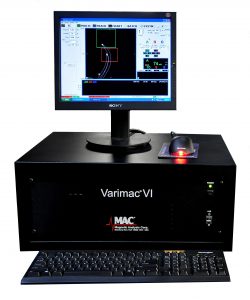

VARIMAC® VI EDDY CURRENT COMPARATOR

Tests Hardness, Alloy, Dimensions and Physical Characteristics in Metal

- Test and sort fasteners, bearings and other cold formed pieces using 100% nondestructive testing.

- Check for hardness and correct grade in wire and bar.

- Test ferrous (magnetic) or nonferrous (non-magnetic) material.

- Use with MAC® Parts Gate for high-speed 3-way sorting.

- Selective circuits separate wanted signals from those of unwanted conditions.

- Contact MAC to arrange for a no charge comparator trial test of your product.

The Varimac® VI performs fast, convenient sorting of metal parts. When used with MAC’s Part Gates, parts can be sorted and counted at speeds up to six parts per second into three separate groups.

The Varimac VI Eddy Current Comparator is most commonly used to test bars, rods, wire, metal parts and tubing. Its high-speed, continuous operation and reliability in production environments help to make 100% nondestructive testing (NDT) economically feasible. The Varimac VI is also often used for checking alloy and hardness in bar or wire.

- Simple operation: a test coil, a balance coil, known samples of your part, a monitor, and the Varimac VI instrument are all you need to set up your test.

- Vector presentation of the test signals lets you easily set up the target regions and thresholds to identify conditions and separate your parts.

- After your initial setup, Varimac runs automatically.

- Convenient counter display on screen shows the number of parts in each region.

- Includes lockout to prevent unauthorized changes to settings.

- Operation can be checked from a remote monitor.

570 Parts Gate

About Eddy Current Testing (ECT) Comparators

Eddy current comparators operate on the principle that when a metal part is placed inside or near a test coil that is excited by an alternating current, the voltage output from the coil will be affected. This effect is directly related to the permeability, conductivity, and physical dimensions of the part. Essentially, the instrument “compares” all these variations in the test part to conditions in a known sample. If the test is for variations in just one property, those differences must be greater than differences that may occur In other properties so they can be separated using the instrument’s selective circuits.

Variations in hardness or heat treatment, for example, create a change in permeability; changes in alloy affect conductivity; and significant dimensional changes affect both conductivity and permeability. These changes in the coil result in screen signals that can be selected based on differences in amplitudes, phase angles or harmonic distortions.

The best way to determine if a comparator will make the exact separation you need is to submit a known sample to MAC for a no charge trial and report. Contact MAC to find out more.

COMPARATOR TECHNOLOGY IN NDT

A frequent challenge in manufacturing and industry is how to separate different parts that have been intentionally—or accidentally—mixed. Electromagnetic comparators can be used to accomplish this quickly and economically.

- This type of instrument “compares” variations in a test part to conditions in a known sample.

- When a metal part is placed inside or near a test coil that is excited by an alternating current, the voltage output from the coil will be affected. This is the basic principle employed by all electromagnetic comparators.

- The kinds of mixes that comparators will separate typically involve variations in alloy, heat treatment, hardness, structure, dimensions (including length) and certain alternating current, the voltage output from the coil will be affected.