TacTic® MATERIAL HANDLING

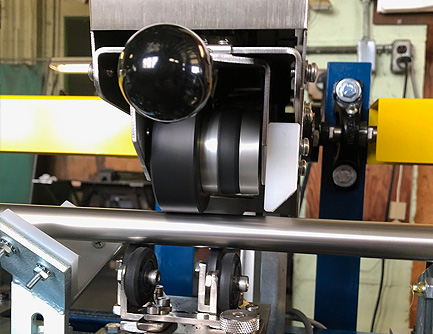

Model 204 and 205 Series Air-Actuated “Extended” Drive Units

Model 204 and 205 Series Air-actuated “Extended” Drive Units are overhead drive wheels. They are exactly the same as those used on TacTic® Model 76 Series Testers, except they are located along the lengths of the first input and output Idler Sections. Using power supplied by the Tester drive motor, these units help move heavy or crooked material or prevent undue vibration of light tubes or bars.

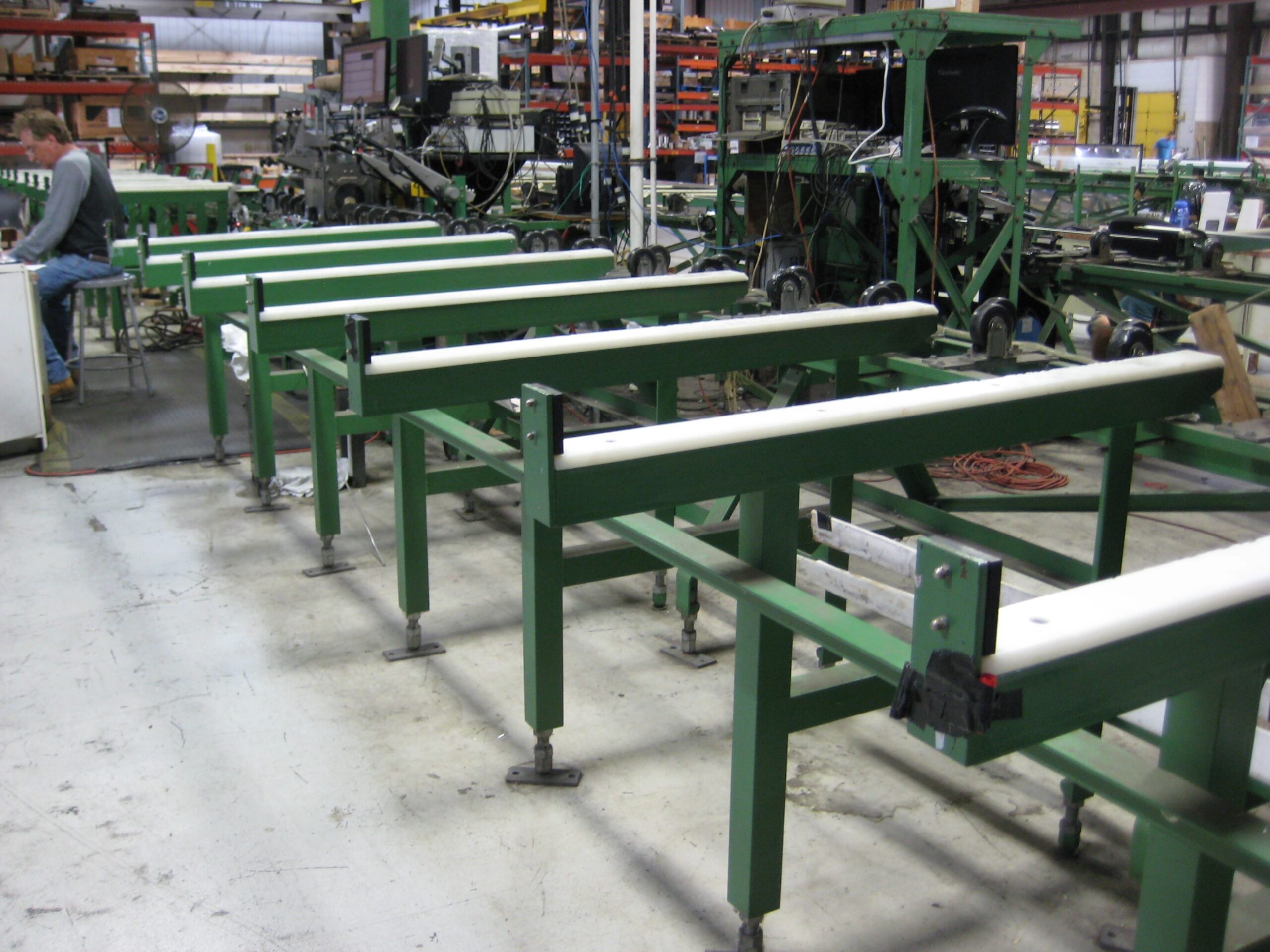

Model 150 Series Storage Rails

Model 150 Series Storage Rails are available for use adjacent to output Idler sections. Model 151 Series Storage Rails, with guide “ramps” for manual loading, can be used adjacent to Input Idler sections. These come in various load-carrying abilities and storage lengths.

Model 190 Series Sorting Racks

This series of racks have one “accept” bin and either one “reject” bin (191 Series) or two “reject” bins (192 Series). They are available for piece weights up to 11 lbs/ft (191/192); 55 lbs/ft (191H/192H) and 100 lbs/ft (191K/192K) corresponding to 16, 80 and 150 kg/m. See Bulletin 1000.

There are two ways to divert unloaded material into accept or reject bins: by manual push-button operation or automatically through the use of a Model 1088 Marker/Sorter Controller. See Bulletin 1000.

Also available is the 191B Belt-Fed Sorter for flat sided materials. When a piece is rejected, “gates” rise and the piece is routed to the reject bin. Good pieces are conveyed over the gates on motorized belts which carry the piece to the accept bin.

Model 187/188 Series Unloaders

Model 219 Series Loaders

These loaders consist of multiple stations of forward-sloping, plastic-covered storage arms with coordinated adjustable end stops for loading different material diameters. Pneumatic or hydraulic cylinders raise lifting arms which allow one piece to roll onto the input conveyor while holding back the rest of the pieces. The machine can be started automatically or by push button (with optional Model 86 Controller).

The loaders come in “Standard Duty” (219), “Heavy Duty” (219H) and “Extra Heavy Duty” (219K) models for pieces of 40, 55, and 100 lbs/ft (60, 80 and 150 kg/m) respectively.

Also available is the 219B for flat-sided materials that utilizes a motor-driven belt to feed material to lifting arms for placement on the idler conveyor.

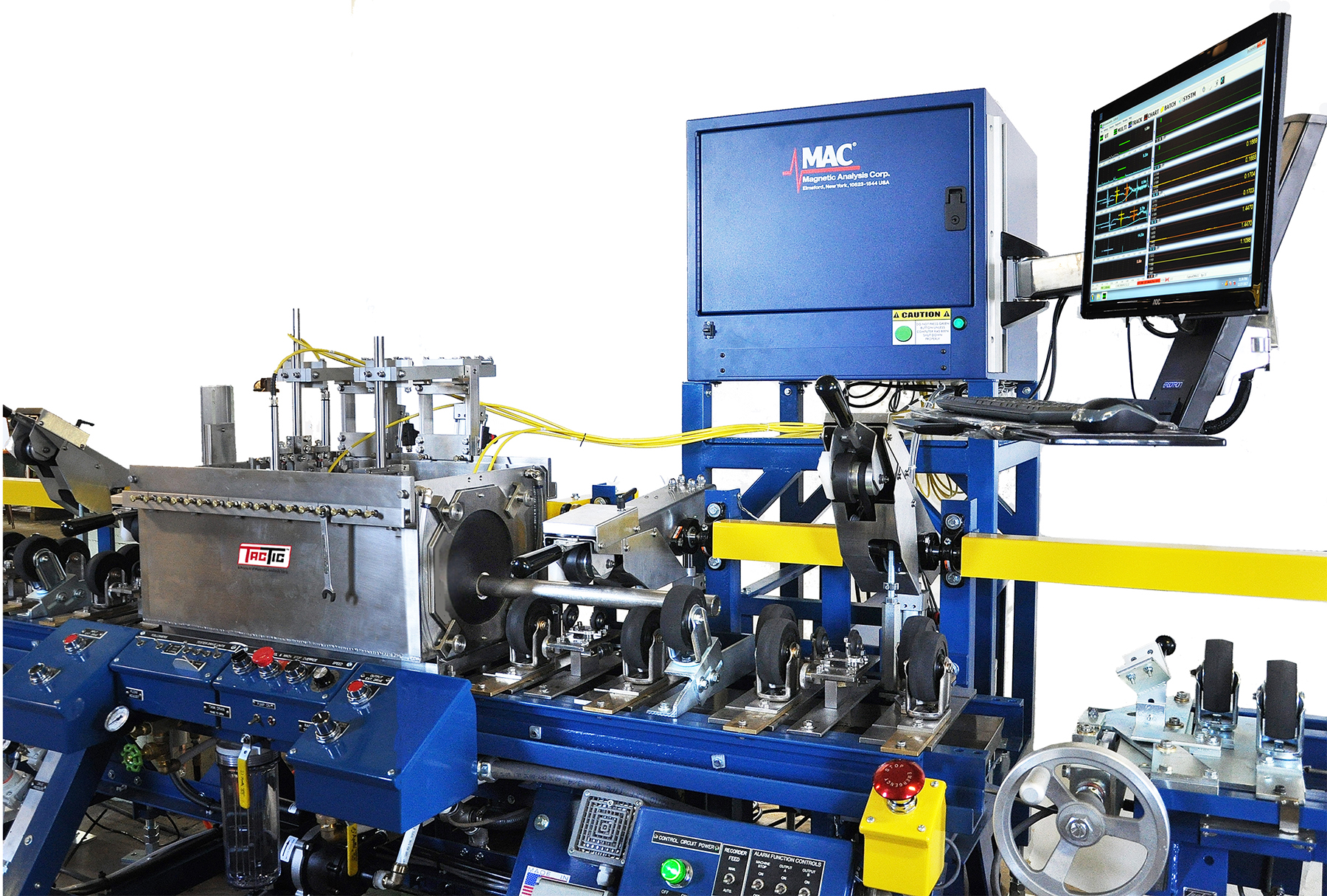

ULTRASONIC TECHNOLOGY IN NDT

MAC’s line of ultrasonic test systems can accommodate a full range of applications, including those requiring sophisticated high speed rotary testing.

TacTic™ Model 76EX-24 “Spin the Tube" Immersion Style System