MINIMAC® II SINGLE- OR 2-CHANNEL DIGITAL TESTER

Minimac® II lets you take advantage of eddy current technology’s versatile capabilities to deliver high-performance testing for tube, bar, wire and parts. With an embedded host computer, this fully digital instrument provides up to two test channels of Flaw, Absolute or any combination, at an economical cost.

- Detect short surface and some subsurface defects, including laps, slivers and cracks in tube, bar, wire and parts.

- Inspect for long, continuous defects.

- Find weld line faults including short ID or OD defects.

- Test magnetic and non-magnetic grades.

- Use up to two test channels of flaw, absolute or any combination.

- Operate at speeds up to 4000 f.p.m. with standard test coils. Operate at higher speeds with wide-spaced coils.

- Operate with one or two test channels for encircling coil applications.

- Use two channels for rotary spinning probe systems.

- Supplied as a one channel instrument with an optional second channel.

MINIMAC® 50 & 55

Economic, Single-Channel Eddy Current (ECT) Testers For Simple Inspection of Continuous Product

- Affordable, compact ECT testers offer high performance at a low cost.

- Both designs operate at speeds over 4000 f.p.m. (with standard coils), take up less space, and do not require cooling. (Higher speeds achievable with wide-spaced coils)

- Detect short surface and some subsurface defects in tube, bar, wire and rod.

- Designed with software controls for all functions including phasing, filtering and sensitivity.

- Full-color polar and linear monitor displays of real time, true wave form signals.

- Enable on-site or remote location review.

With the Minimac® 50 and Minimac® 55, you no longer have to sacrifice performance for price.

These powerful, compact eddy current testers offer the robust capabilities of our top of the line, proprietary MultiMac® software, yet are much more affordable than you might think.

Features:

- Simple operation: can be set up with a monitor on site, or via a computer network.

- Offer a broad frequency range – 1KHz to 5MHz.

- Typical applications include:

- Detecting short surface and some subsurface defects, including laps, slivers and cracks.

- Testing magnetic and non-magnetic grades.

- Finding weld line faults, including short ID or OD defects.

- Checking continuity and locating welds in single- and multi-conductor insulated wire and cable.

- Testing cut lengths or continuous product, on-line or off-line.

- Detecting magnetic inclusions with MID version of the Minimac.

- Minimac® 55, used with optional encoder, enables end suppression.

Minimac® 50

Designed for simple inspection of continuous product.

- An excellent choice for dedicated, continuous production testing of wire, cable and tube where simple setup without the need for constant operator adjustment is desired.

Minimac® 55

Tests cut lengths or continuous product.

- Finds weld line faults, including short ID or OD defects. Used with optional encoder, enables end suppression and automatic adjustment of filters to the optimum frequency for the line speed.

EDDY CURRENT TECHNOLOGY IN NDT

MAC’s® Eddy Current Testing (ECT) systems incorporate computer-based test instruments and test coils that use two ECT coil technologies: encircling and sector coils, and spinning or rotary probe coils.

- Encircling and sector Eddy Current coil tests perform in this manner:

- The product is passed through or adjacent to an electrical test coil, which has been excited by an alternating current.

- This induces a flow of eddy currents around the test material or in the case of a sector coil, in the area under the coil.

- Short, intermittent anomalies or flaws cause a variation in the eddy current pattern, which the instrument detects.

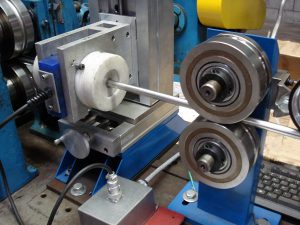

Eddy Current Encircling Coil unit Inspecting SS Welded Tube