INSPECTING STAINLESS STEEL WELDED TUBE

MAC’s Minimac® 50 and 55 eddy current instruments are high performance yet affordable, compact testers that are used to inspect a range of tubing, including stainless steel, copper, cold drawn welded, and seamless.

Operating at speeds up to 4000 fpm (with standard coils. Higher speeds achievable with wide-spaced coils), they detect short surface and some subsurface defects, including laps, slivers, cracks and weld line faults. Sensitivity, phase and filter are easily set on-screen while viewing a full color polar and linear display of real time, true wave form signals. Convenient review of test results on-site or remotely is included. These powerful, compact eddy current testers offer the robust capabilities of MAC’s top of the line, proprietary MultiMac® software, yet are much more affordable.

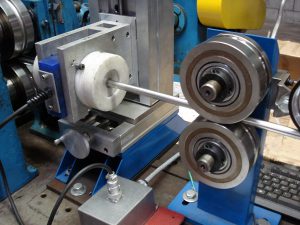

Eddy Current Encircling Coil unit Inspecting Stainless Steel Welded Tube as part of a MultiMac® test system.

Now celebrating more than 90 years of serving the metals industry with nondestructive test instruments and systems, MAC’s experienced and knowledgeable Engineers and Representatives can advise customers on selecting the most effective solutions, including instrumentation, test coils and sensors, rotary test heads, benches, and accessories for ensuring their products meet industry standards.