COMPARATOR TECHNOLOGY IN NDT

A frequent challenge in manufacturing and industry is how to separate different parts that have been intentionally—or accidentally—mixed. Electromagnetic comparators can be used to accomplish this quickly and economically.

- This type of instrument “compares” variations in a test part to conditions in a known sample.

- When a metal part is placed inside or near a test coil that is excited by an alternating current, the voltage output from the coil will be affected. This is the basic principle employed by all electromagnetic comparators.

- The kinds of mixes that comparators will separate typically involve variations in alloy, heat treatment, hardness, structure, dimensions (including length) and certain other conditions.

- The effect that the part has on the output of the coil is directly related to the permeability, conductivity and physical dimensions of the part.

- If the test is for variations in just one property, those differences must be greater than those that may occur in other properties so that they can be separated using the instrument’s selective circuits.

- Variations in hardness or heat treatment, for example, create a change in permeability; changes in alloy affect conductivity; and significant dimensional changes affect both conductivity and permeability. These changes in the coil result in screen signals that can be selected based on differences in amplitudes, phase angles or harmonic distortions.

The best way to determine whether a comparator will make the particular separation that you need is to conduct a trial of the equipment with actual samples of your test material.

As a special service to our customers, a material sample can be sent to our trained staff of experts for a no-charge trial and report. For complete details, call or email MAC®.

- The amount of change produced will be affected by the excitation frequency of the coil, the conductivity or permeability of the material, and the sensitivity of the instrument.

- Non-magnetic (non ferrous) parts have differences in electrical conductivity.

Magnetic (ferrous) materials have differences in both electrical conductivity and magnetic permeability, although the permeability differences generally have a greater effect

Magnetic (ferrous) materials have differences in both electrical conductivity and magnetic permeability, although the permeability differences generally have a greater effect- The voltage output of the coil may be affected in three different ways:

- Amplitude (a change in the magnitude of the voltage output. Dimensional changes will produce a difference in amplitude.

- Phase (a change in the time relation to the output voltage). Dimensional changes in non-ferrous materials will usually produce a phase change.

- Harmonic Distortion (occurs when high power is used on ferrous material to nearly saturate the part). Harmonic Distortion is an excellent way to indicate difference in care hardness in ferrous material.

- For example, variations in hardness or heat treatment create a change in permeability. Changes in alloy affect conductivity. Significant dimensional changes affect both conductivity and permeability. These changes in the coil result in screen signals that can be selected based on differences in amplitudes, phase angles or harmonic distortions.

- Comparators can operate with either one coil (absolute method) or two coils (differential method). Generally, the use of the two-coil system provides greater sensitivity.

- Coils can be encircling or probe type.

- The frequency of the excitation voltage determines what type of differences will be seen between two parts. Therefore, a comparator that operates on more than one frequency, or has a variable frequency through a given range, has more selectivity.

- Filtering capabilities in electromagnetic comparators allow for an examination of the specific frequency which is most affected by the material being inspected, while ignoring the effects of other frequencies.

- An elimination filter can also be used to minimize the effect of a given frequency so that other frequencies can be examined.

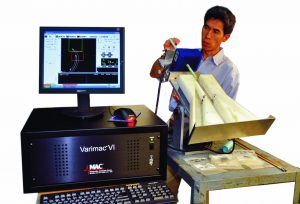

Varimac® Comparator with Test Coil and 570 Parts Gate