ECHOMAC® FD6 MULTICHANNEL UT

For Flaw Detection, Thickness & Dimensional Measurement in Tube & Bar.

- Versatile Ultrasonic tester with superior performance and versatile, intuitive operation.

- For full inspection of tubes, pipes and bars, plate and weld.

- Operate on or off line.

- Upgrade and/or replace older ultrasonic testers.

- Use with rotary, spin-the-tube, squirter and bubbler installations.

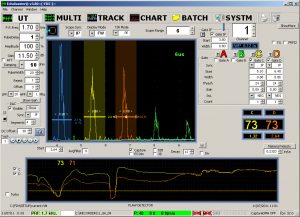

- Vivid, real time, flicker free full color display of test signals, thresholds and settings.

- Up to 32 independent channels in one instrument.

- Model 6A is GE Qualified as of 9-6-16 for P3TF31 Class A & B, & P29TF82 Class A & B, typical requirements for nuclear and aerospace applications.

Building on the success and wide acceptance of earlier Echomac® models, the FD-6 and 6A achieve new levels of improved signal to noise ratio, finer adjustments, improved thickness resolution, repeatability, and reliability.

Features:

- Flaw detection, thickness measurement, dimensional evaluation, eccentricity calculation, weld inspection and characterization.

- Set up and control of all key test parameters on one screen with a click of the mouse or keyboard.

- Thresholds can be moved by selecting and dragging on screen and a “Global” key allows parameters for several channels to be adjusted at once, or copied from one channel to another.

- The chart screen shows strip charting and defect logging of all events, up to 32 channels or functional groups, in live or replay mode.

- Full tracking of end suppression, defect marking capability, and customizable data retention are included

- Use with MAC’s Echomac® Rotary Ultrasonic Transducer assembly as well as with other existing immersion, bubbler or squirter type and “spin the tube” installations

- Can replace any commercial ultrasonic instrument in almost any application.

Echomac® screen display of tube wall thickness measurement

- Includes extremely flexible tracking, sorting and recording functionality that enables very close end testing and normalized recording which compensates for the many inspection planes necessary in complex multi-transducer configurations.

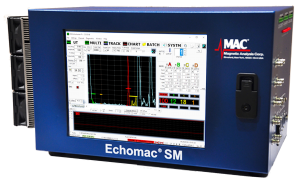

MAC also offers an Echomac® Small unit. Available with up to eight channels of electronics to detect and evaluate thickness, flaws and eccentricity, this UT tester is housed in a convenient, smaller cabinet. It features a closed loop heat exchanger to ensure proper operating temperature, as well as protection from the outside environment. Echomac® Small can be equipped with an optional monitor and keyboard if required. This instrument can be used in conjunction with bubbler or immersion tank systems, or with a test bench or in laboratory applications. The Echomac® Small is available in the FD4, FD6 or FD6A versions

ULTRASONIC TECHNOLOGY IN NDT

High-speed Ultrasonic (UT) Systems enable a full volumetric examination of materials and are designed to detect surface, subsurface, internal and dimensional flaws.

This type of testing utilizes high-frequency sound waves that are transmitted throughout the material being tested in order to conduct a thorough inspection.

- Ultrasonic inspection can be used to detect surface flaws, such as cracks, seams, and internal flaws such as voids or inclusions of foreign material. It’s also used to measure wall thickness in tubes and diameters of bars.

- An ultrasonic wave is a mechanical vibration or pressure wave similar to audible sound, but with a much higher vibration frequency. For NDT purposes, the range is usually from 1MHz to 30MHz or higher.

- Depending on the test requirements, these waves can be highly directional and focused on a small spot or thin line, or limited to a very short duration.

- Two methods of UT are used for flaw detection – Shear and Compression Wave.

Echomac® 150mm Rotary System