GENERAL RELEASE

Magnetic Analysis Corp. will feature NDT instruments and systems for testing tube, pipe, bar, and wire at Stand #6/H20 at Tube 2020 Düsseldorf. Highlights include MAC’s latest developments in Eddy Current, Magnetic Flux Leakage (AC and DC), and Ultrasonic technology, including the new Phased Array systems.

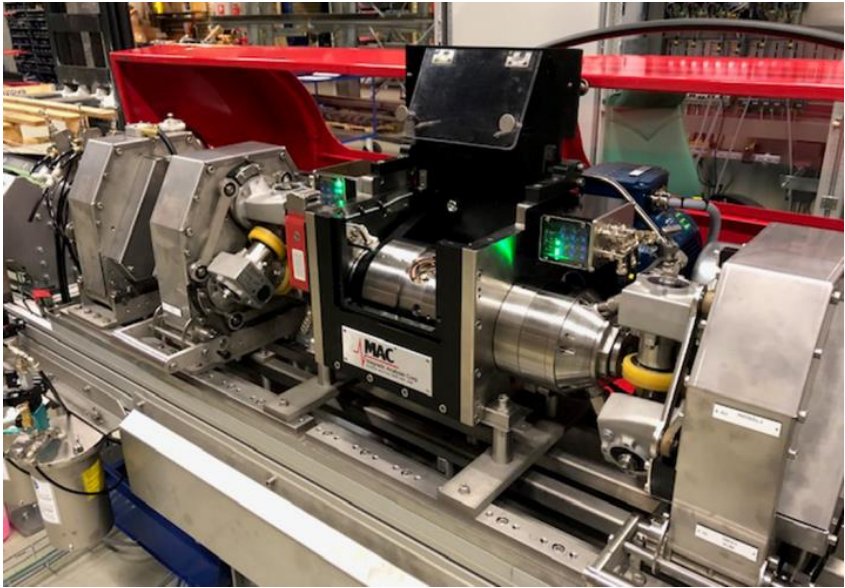

The Echomac® 25mm UT Rotary, designed for high-performance applications such as tubular products for nuclear and aerospace installations, will be showcased. This equipment provides 100% coverage at high throughput rates on thin-wall products ranging from 5 to 25mm in diameter. Its compact 630mm length allows easy installation when upgrading inspection lines. It can test wall thicknesses as thin as 0.3mm and tubes as short as 1 meter. Key features include a transformer design for improved signal-to-noise ratio, enhanced bandwidth, zero channel cross-talk, 8,000 RPM running speed, precision test blocks and transducer holders, and convenient transducer angle adjustment. The 25mm Rotary joins MAC’s UT Rotary lineup, which accommodates up to 500mm capacity. Paired with MAC’s Echomac® FD6/6A instrumentation, it enables detection of ID/OD, longitudinal and transverse flaws, wall thickness variations, and dimensional issues such as eccentricity and ovality. The Echomac® Model 6A holds GE Qualification for P3TF31 and P29TF82 Class A & B, meeting the stringent quality standards of aerospace and other critical applications.

Also featured is the Echomac® SM, a compact and versatile UT instrument with up to 8 test channels, capable of inspecting tubes for wall thickness, flaws, eccentricity, and dimensions.

The 20mm Rotomac® will be presented for high-speed inspection of small-diameter tube and wire, detecting surface flaws such as seams and laps. Operating at speeds up to 18,000 RPM, it delivers highly sensitive non-contact testing for products ranging from 2 to 20mm in diameter. Additional features include easy-to-set Distance Compensation (critical for testing ovate wire), a convenient dial-in diameter guide for quick adjustments, and simple probe replacement with quick twist-on bushing holders.

MAC’s experienced engineers will be available at the booth to discuss the full range of nondestructive test systems, including:

- The Echomac® Phased Array system for weld zone profiling and defect detection in ERW tube

- Ultrasonic/flux leakage multi-test systems for OCTG pipe up to 500mm

- A variety of other NDT solutions for tube producers

With over 90 years of expertise, MAC remains a trusted provider of nondestructive test equipment and systems for tube, bar, and wire manufacturers, ensuring a thorough understanding of customer inspection needs.

Echomac® 25mm Ultrasonic rotary for inspecting tube and bar