GENERAL RELEASE OCTOBER 2020

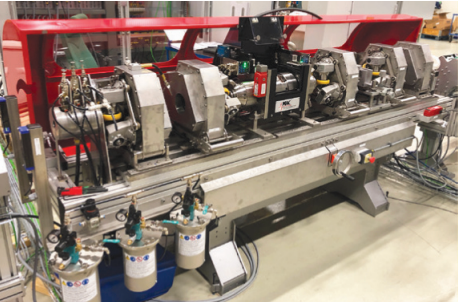

Magnetic Analysis Corp.’s new 40mm Rotomac® Eddy Current Rotary offers enhanced convenience for detecting seam-type surface defects in cold-drawn wire, cut-length bar stock, and parts forming. A single-handle external probe adjustment allows quick, safe dimensional changes without opening the rotary.

Operating at 6,000 rpm, the 40mm Rotomac® features two test channels and accurate distance compensation to ensure uniform defect signals, even with off-center or out-of-round material. Currently installed at a mill producing hot-rolled steel bars for sucker rods, the 40mm Rotomac® is a key addition to MAC’s line of eddy current rotaries.