Magnetic Analysis Corp.® (MAC), a global leader in nondestructive testing (NDT) since 1928, is proud to announce a partnership with PITCO LLC, owned by Artic Testing and Inspection. Under this agreement, MAC offers the MacFlux DC Series, a premium MFL test system pioneered by PITCO LLC.

Engineered for OCTG Pipe Producers

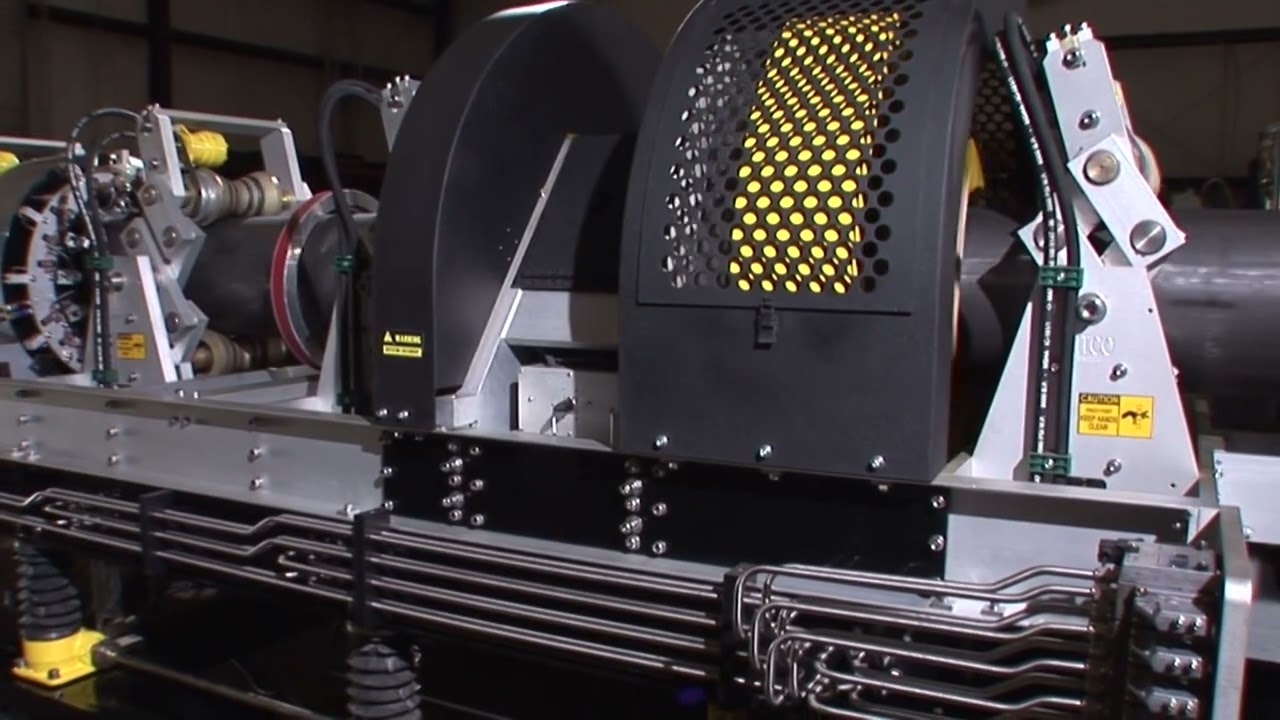

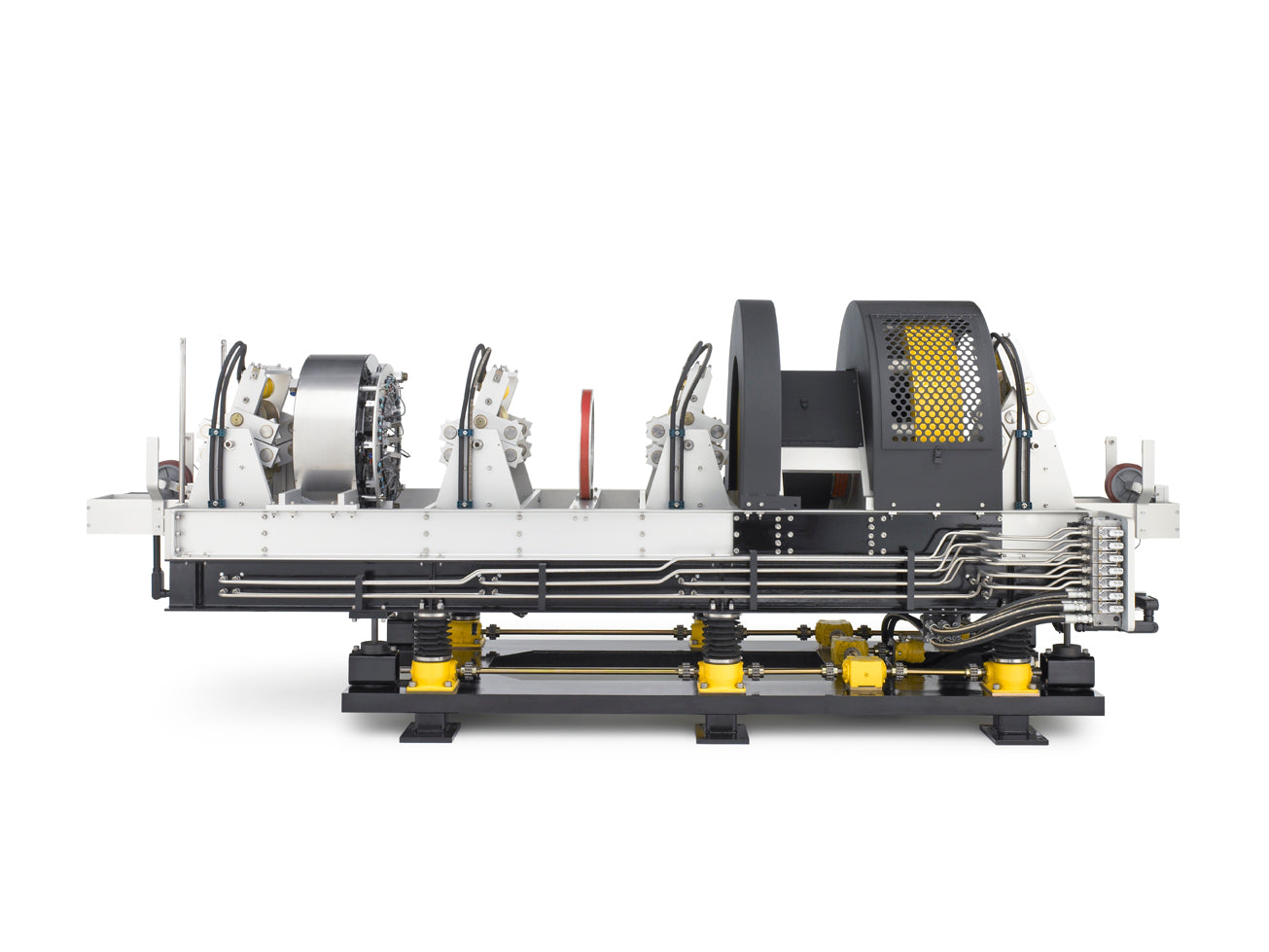

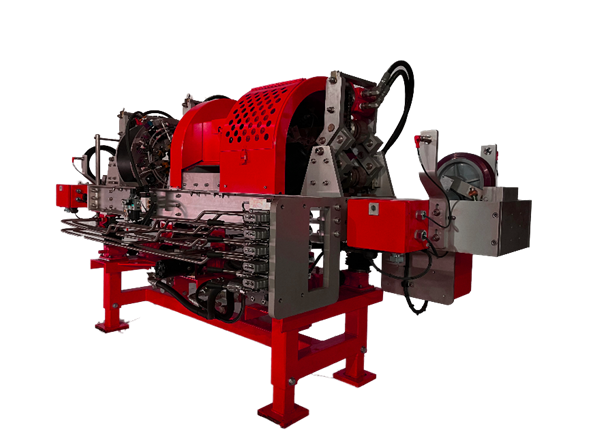

The MacFlux DC Series is specifically designed for high-volume, 24/7 production lines common in steel pipe mills, with powerful inspection capabilities tailored for Oil Country Tubular Goods (OCTG). These four-function EMI units offer unmatched detection precision, production speed, and reliability—everything manufacturers need to meet rigorous quality standards and keep operations running smoothly.

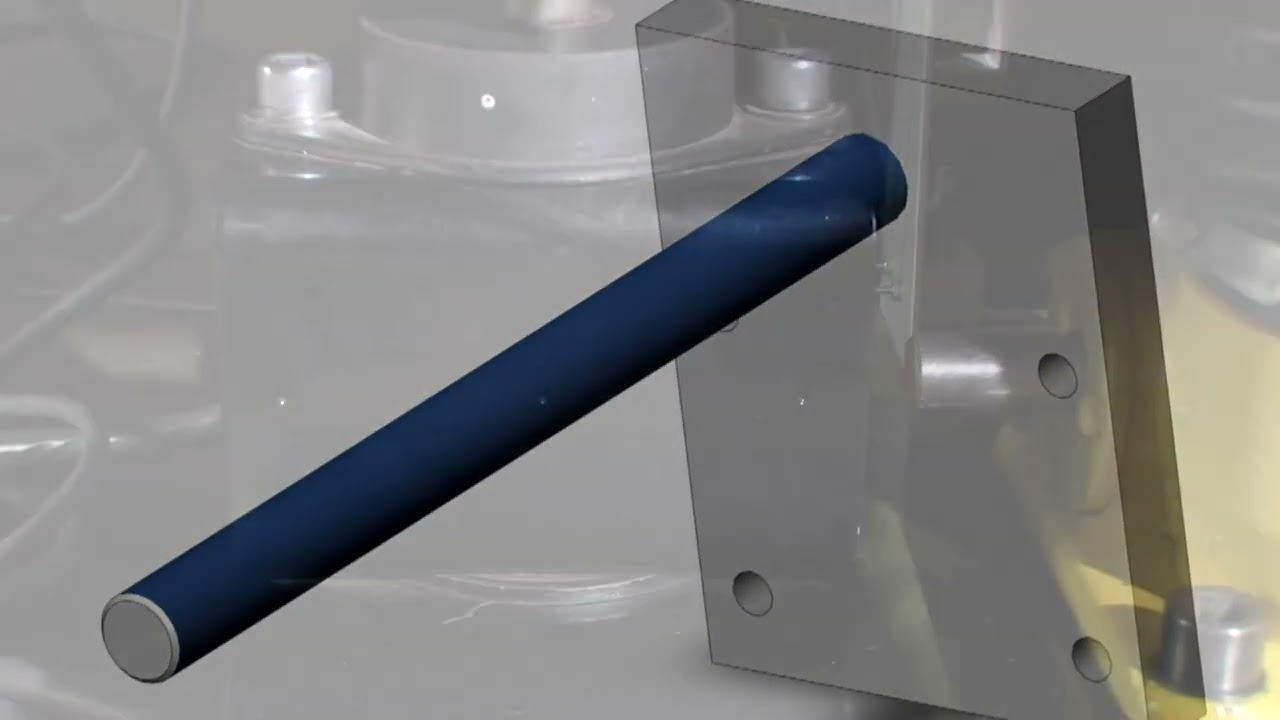

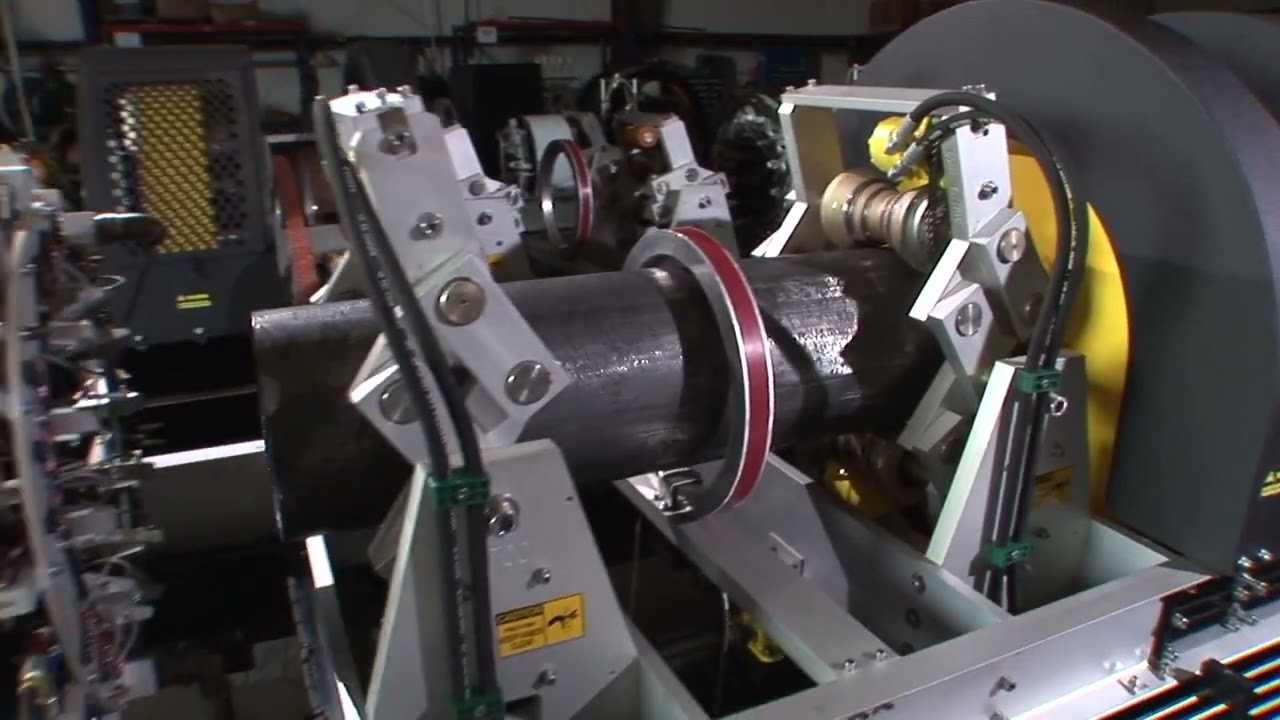

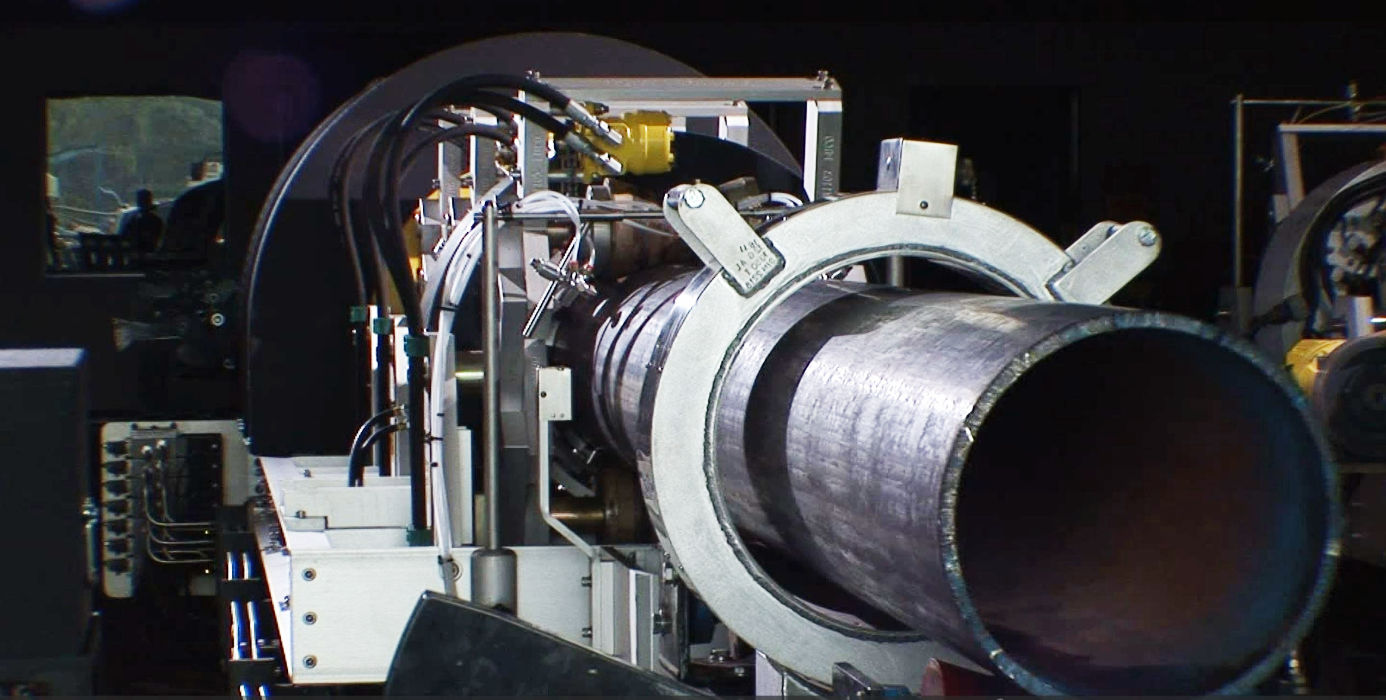

A specialized horizontal stable slide assembly minimizes unwanted side-to-side motion to improve inspection quality. Using precision shafts and rubber bushings, this design delivers advantageous, stable MFL inspection.

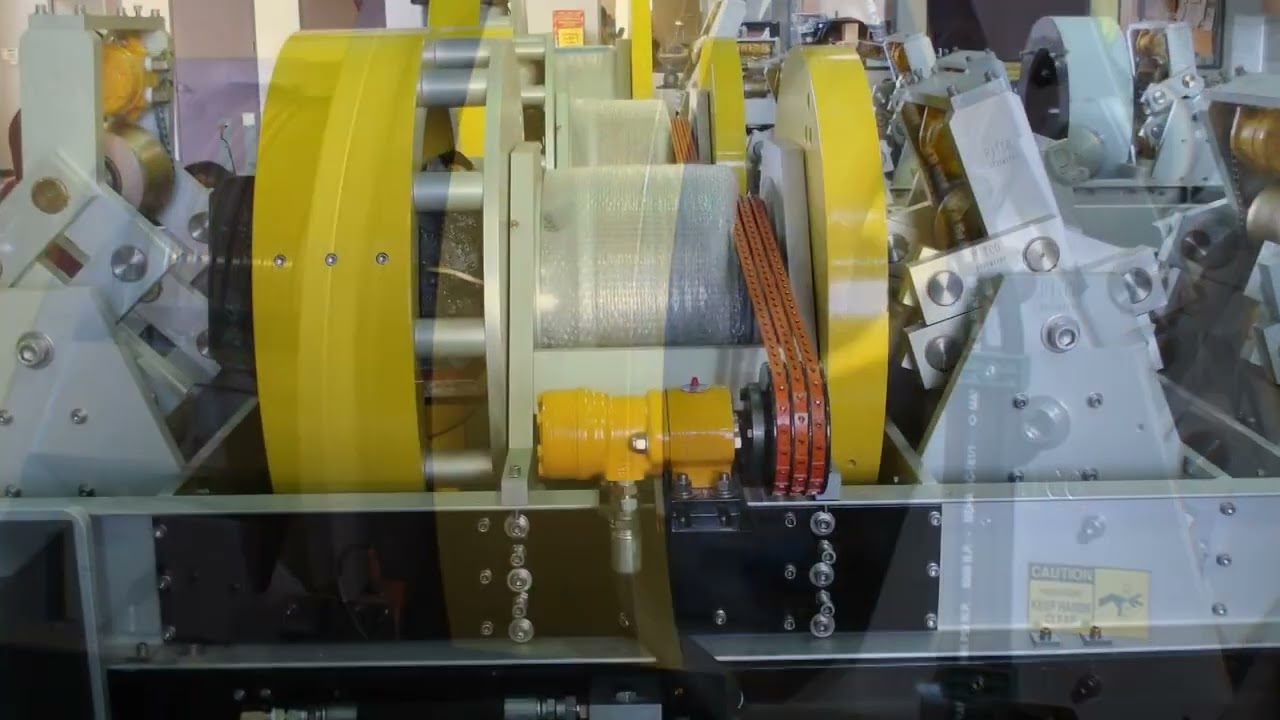

The high-strength aluminum center section, reinforced with steel and composite materials, creates a rigid, flex-free platform that enhances inspection accuracy and extends equipment life.

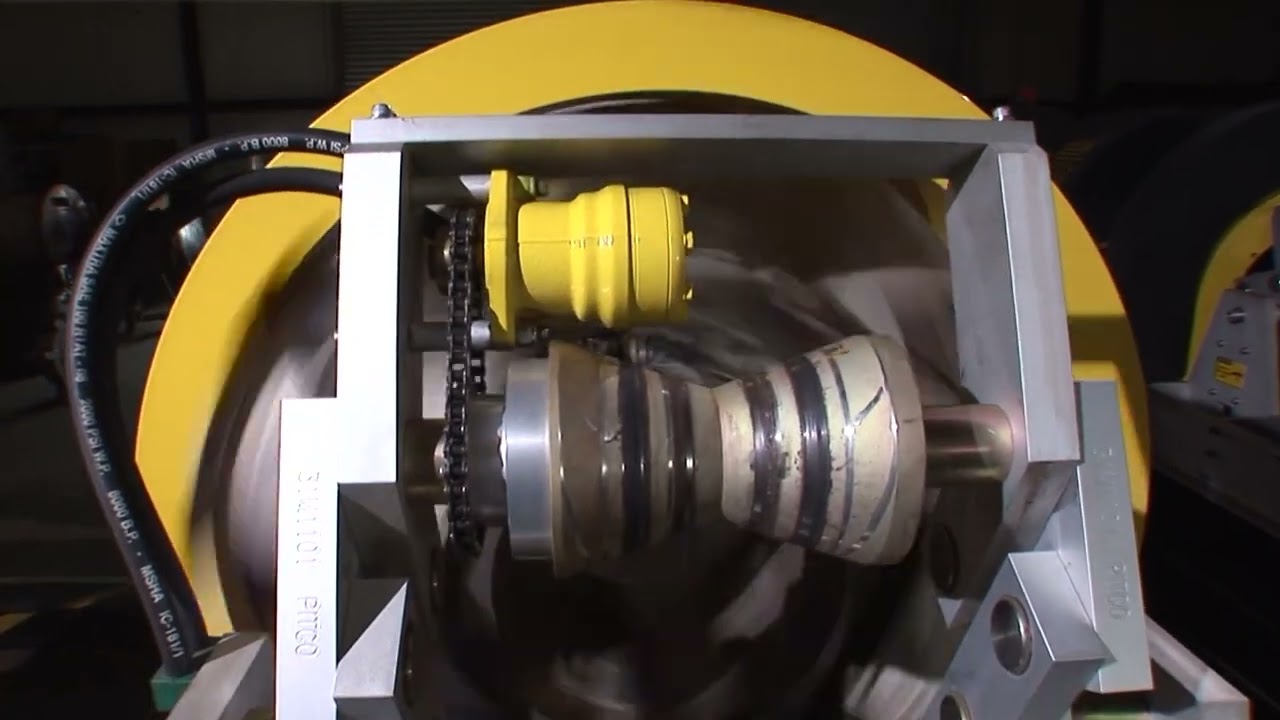

The balance disc counterweight design evenly distributes the weight of the rotating head assembly, reducing vibration and bearing wear for smoother, more stable operation.

By enlarging the flux ring and extending the pole pieces, the system concentrates magnetic flux and minimizes the bloom effect, delivering consistent signal detection across the sensing area.

Each DigiTech MFL inspection unit includes a standard dual demagnetization system that reduces residual magnetic fields in inspected pipe to meet or exceed API specifications.

An Allen Bradley PLC with LCD touchscreen controls the entire pipe inspection process, allowing operators to adjust parameters like conveyor speed, rotating head speed, and pinch roller timing.

The standard electronics cabinet keeps components cool and protected while housing all critical electrical and computer systems. Built-in safety features, precision power controls, and backup power ensure reliable, stable performance even during outages.

MacFlux DC 3100 features the capacity to inspect OCTG from 4 1/2” (114.3mm) through 14” (355.6mm) plain-end material.

MacFlux DC 2100 has the capacity to inspect OCTG from 2 3/8” (60.3 mm) through 8.00” (203.2 mm) plain-end material for longitudinal and transverse flaws.

MacFlux DC 1000 inspects threaded and coupled pipe from 2 3/8” (60.3 mm) to 3 1/2” (88.9 mm) OD, detecting longitudinal and transverse flaws with 16 longitudinal and 8 transverse channels, offering >100% variable coverage for longitudinal and transverse defects.