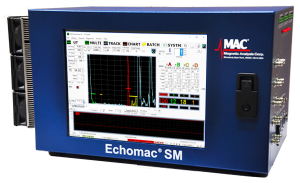

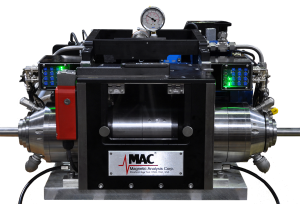

Echomac® II: Advanced Ultrasonic System for Flaw Detection, Dimensional & Thickness Measurement in Tube, Bar, Plate & Weld

Versatile, high-performance ultrasonic tester designed for modern NDT requirements

Echomac® II builds on MAC’s proven legacy of ultrasonic testing excellence, offering enhanced signal fidelity, precision control, and advanced real-time processing—all in a flexible, user-friendly platform. Designed for full volumetric inspection of tubes, bars, plates, and weld zones, the Echomac® II system is ideal for high-performance applications in industries such as aerospace, nuclear, automotive, and metals production.

Key Features & Capabilities

-

High-Precision Flaw Detection

Detect longitudinal, transverse, and off-angle defects with real-time signal processing and configurable alarms for up to 32 independent channels. -

Simultaneous Dimensional Measurement

In three-transducer mode, the system simultaneously measures OD, ID, and wall thickness with superior resolution—better than 1 µm for steel in PR mode. Eccentricity and ovality evaluations are also supported. -

Advanced A-Scan Visualization

Flicker-free, full-color oscilloscope displays with multiple modes (FE, PHE, NHE, RF) offer vivid signal clarity. Persistence and decay functionality help highlight transient or infrequent defects. -

Digital Strip Chart & Reporting

Real-time strip chart logging for each gate and channel with summary reports at the end of each production run. Monitor and record defect events, part counts, reject rates, and traceability data. -

Optimized Pulse Control & Gating

Fully adjustable pulser (0–225 Vp, 30–500 ns) with configurable damping and delay. Four measurement gates and one interface gate with independent setup per channel. -

Robust DAC Functionality

Supports up to 15 DAC segments per channel with intuitive graphical setup. Combined gain up to 100 dB enables precise evaluation of amplitude-distance characteristics. -

Seamless System Integration

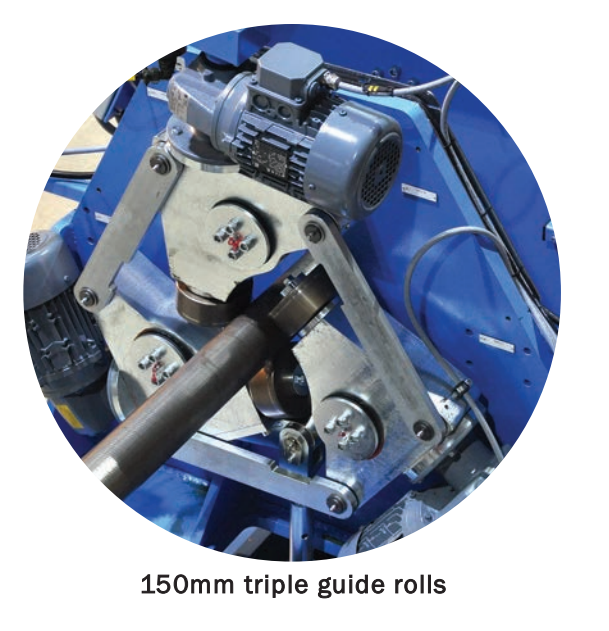

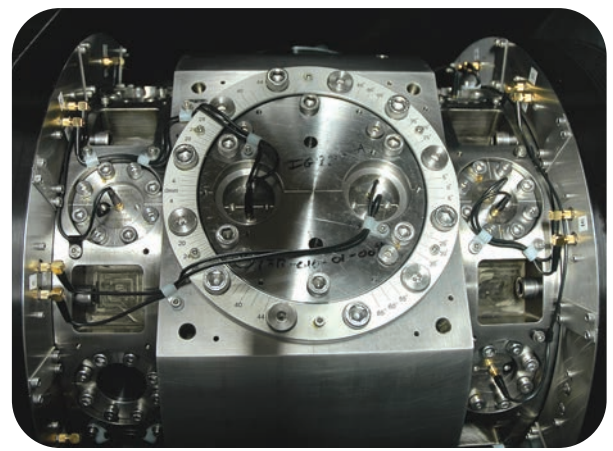

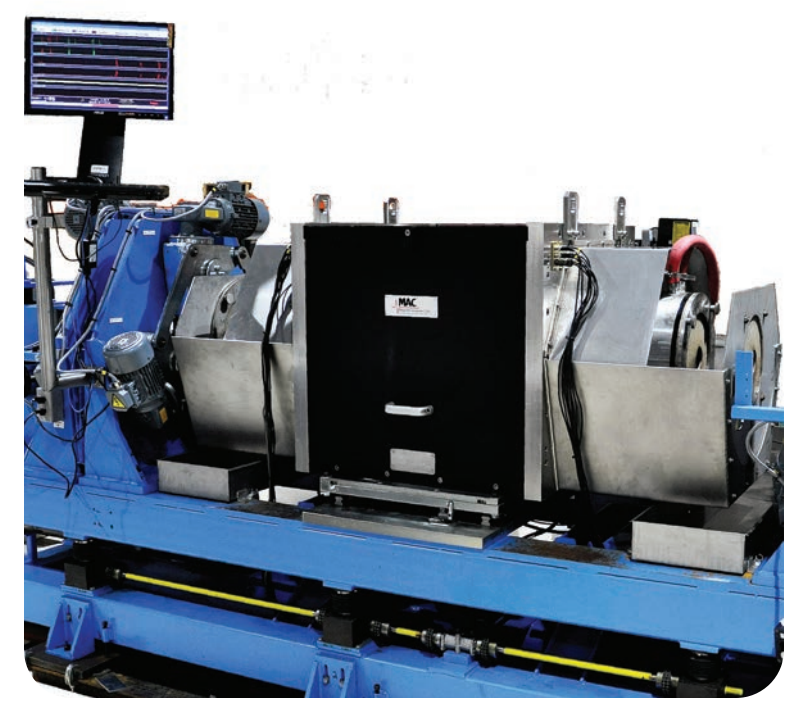

Interfaces with rotary, squirter, bubbler, and spin-the-tube setups. Fully compatible with MAC’s Echomac® Rotary Transducer Assemblies and existing NDT infrastructures.

Technical Highlights

-

Frequency Range: 0.6 to 27 MHz (-3 dB)

-

Receiver Gain: 0 to 100 dB (0.1 dB steps)

-

Digitization: 100 MHz, 8-bit, per channel

-

Pulse Repetition Frequency: 10 Hz to 20 kHz

-

Data Communication: 1 GB Ethernet, TCP/IP protocol

-

Alarm Logic: Configurable for peak/valley, positive or negative threshold detection

-

Tracking & Marking: Fast, hardware-based tube/bar tracking with programmable defect marking

Powerful Real-Time Processing

Each channel is independently managed by embedded ARM processors, allowing real-time flaw and dimensional evaluation without affecting signal acquisition. A 1 GB LAN supports external control and monitoring, while persistent and infinite hold modes enhance defect visibility.

Applications

-

Flaw Detection (ID/OD wall, laminations, inclusions)

-

Wall Thickness & Eccentricity

-

Weld Seam Inspection & Characterization

-

Ovality, OD, ID Evaluation

-

Dimensional Tolerancing for QA/QC

-

Aerospace and Nuclear Grade Testing (GE-qualified Model 6A still available)

Reliable, Field-Tested Hardware

-

Standard Enclosure: 19” rack-mount system; air-conditioned cabinets optional

-

Power: <800 VA (115/230 V, 50/60 Hz)

-

Operating Temperature: 0 to 45°C (32 to 113°F)

You may also like

For use with Magnetic Analysis Test Systems

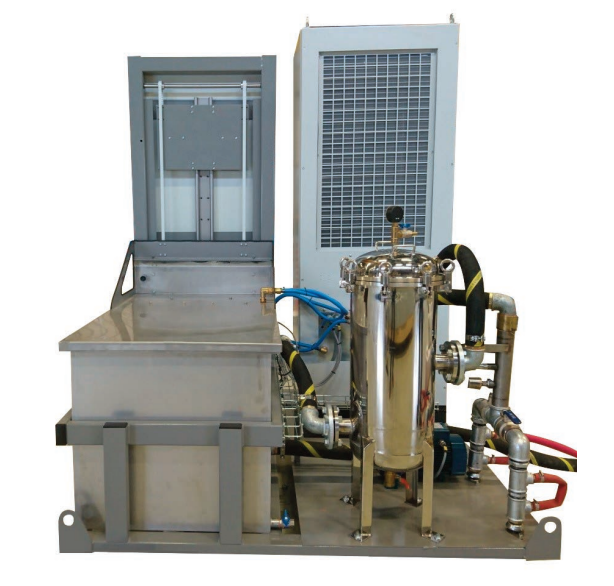

Prevent False Test Signals from Contaminated Bar & Tube Surfaces & Reduce Rotary Cleaning Downtime.

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

Simple, Effective Ultrasonic Instrument With up to 6 Channels

For Inspecting High Precision Small Diameter Tube & Bar

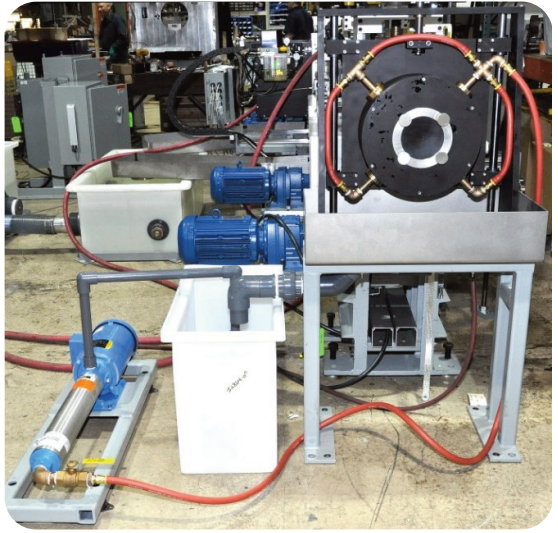

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products

Ultrasonic Rotary Mechanism for High Speed Testing of Round Bar and Tubular Products