Wire and Cable Technology - Top Products of 2025

Magnetic Analysis Corporation (MAC®), Elmsford, NY, USA, a pioneer in nondestructive testing solutions, helps wire mills tackle challenges through its Minimac® digital eddy current test equipment.

The New Era of Magnetic Flux Leakage Testing in OCTG

Edson José Eufrásio and Matt Rutledge dive into the latest developments in Magnetic Flux Leakage (MFL) testing—covering new technologies, evolving standards, and emerging market needs in this discussion titled "A New Era of MFL". Edson José Eufrásio brings over 40 years of experience in NDT, inspection, and quality management across the steel and oil & gas sectors. A former Director of NDT Technology at Vallourec and President of ABENDI, Edson is now consulting for Magnetic Analysis Corporation. He is an ASNT Level III in ET, UT, and MT, with advanced degrees in mechanical and metallurgical engineering and business management. Matt Rutledge, Vice President of PITCO, LLC, has more than 16 years of experience in OCTG inspection and MFL technology. He has led advancements in inspection reliability and process efficiency, implemented ISO 9001:2015 systems, and continues to drive innovation and quality excellence in the oilfield inspection industry.

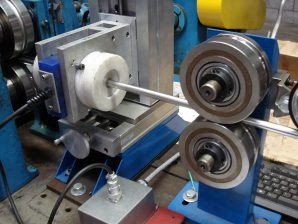

Custom Solution for Testing Large Diameter Tube

The customer, a tube manufacturer in India, faced difficulties when it came to performing electromagnetic testing on larger tubes, with diameters ranging from 180 mm to 250 mm. Their previous testing system, which was based on eddy current testing (ECT) with an encircling coil, was effective for tubes with diameters up to 180 mm. However, the sensitivity of the system, which is inversely proportional to the tube diameter, significantly decreased when testing larger tubes. The customer needed a solution that would maintain the same level of defect detection sensitivity while accommodating the increased tube diameter. This posed a challenge for achieving the required test defect size, through drilled holes (TDH), consistency and defect sensitivity with heavier wall thicknesses.

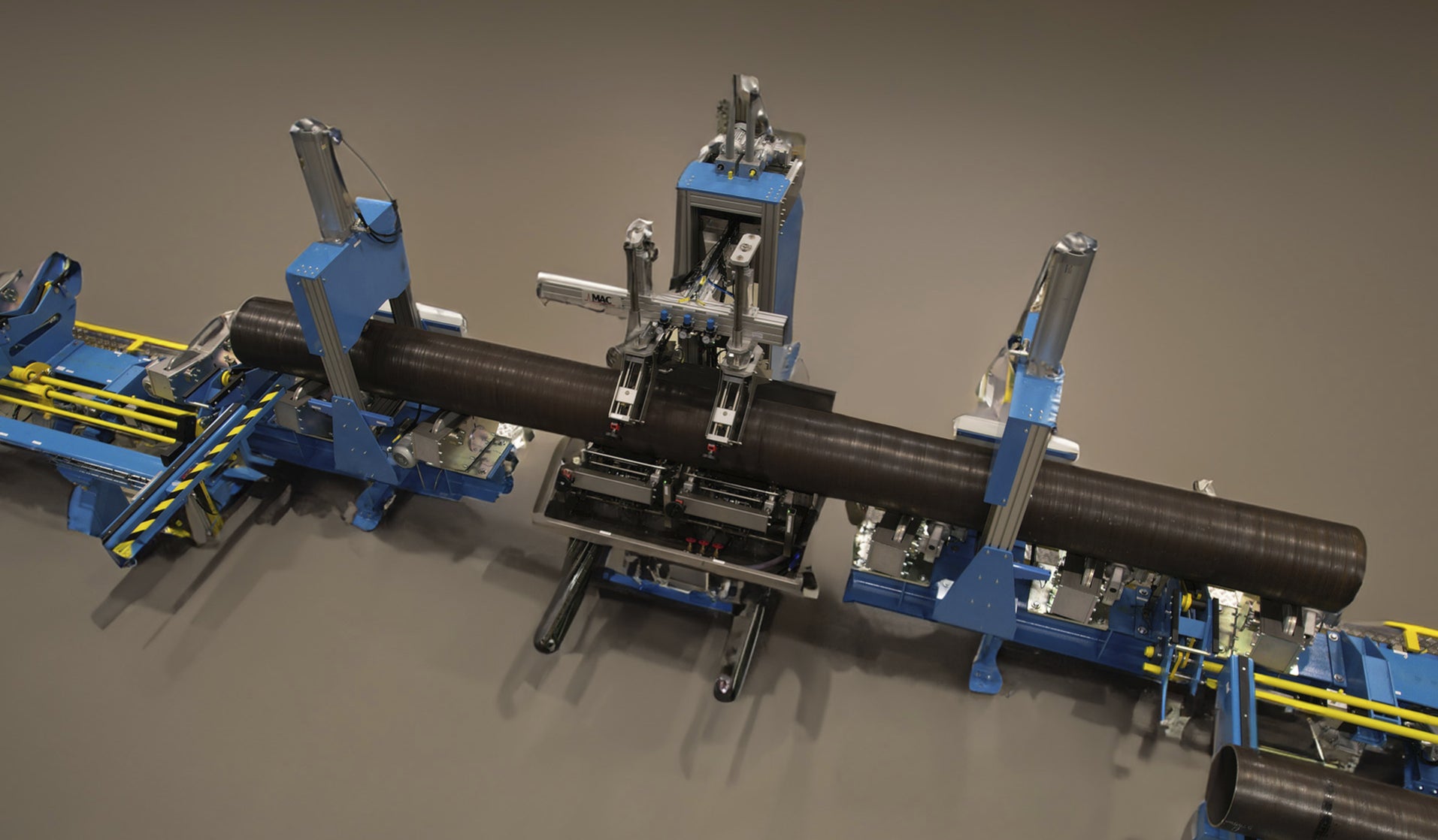

TAKING ULTRASONIC PIPE INSPECTION TO A NEW LEVEL WITH THE ECHOMAC® 500MM TESTER

Responding to the expanding supply of natural gas and oil which has spurred a need for larger diameter tube and pipe, Magnetic Analysis Corp. (MAC) has supplied its largest ever model Ultrasonic Rotary tester to a major Russian pipe producer. Part of MAC’s line of Echomac® nondestructive Ultrasonic testers, this model can inspect tube and pipe up to 500mm (19.6”) diameter.

Aerospace

A test system supplied to a producer of titanium tubes for nuclear applications incorporates MAC’s (Magnetic Analysis Corp.) Echomac® FD-6A ultrasonic instrumentation with a TacTic® ultrasonic transducer immersion tank

AUTOMOTIVE TUBE

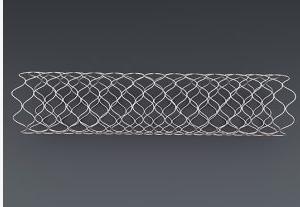

Precision tubes for the automotive industry must meet the highest performance requirements. MAC’s® Eddy Current, Flux Leakage and Ultrasonic systems are often used to inspect tubes destined to be cut into short lengths to be fabricated into a critical automotive component.

WIRE AND ROD

Eddy Current technology is the go-to wire and cable testing method for checking continuity, alloy, surface flaws and other conditions as well as for locating welds and splices. MAC® instruments can handle a range of metal wire including cut lengths, continuous production, stranded, multi-conductor and insulated cable.

WELDED TUBE

There are many welding processes and many tubing configurations and sizes. MAC has extensive experience testing tubes and pipes using eddy current, ultrasonic, and flux leakage technologies. We have a large base of testing equipment lines being used to meet the many different ASTM, API, EN, ISO and other industry quality standards and or customer driven quality requirements.

TUBE ENDS

All nondestructive test (NDT) methods have some limitation in regard to testing to the very end of a tube. These “untested ends” must be cut off, resulting in a substantial loss of product and revenue. To avoid this loss, a manufacturer needs to develop a method to test these ends to meet the tube integrity requirement.

TESTING BAR

Depending on the requirement, situation and the type of material, Eddy Current, Magnetic Flux Leakage and Ultrasonic testing methods can be used together or alone to inspect round, hex, and square bars for defects and integrity. These inspection methods can be applied to carbon steels, stainless alloys, aluminum, titanium, and all other non-ferrous metals. Bars can be as rolled, peeled or drawn and surface improved.

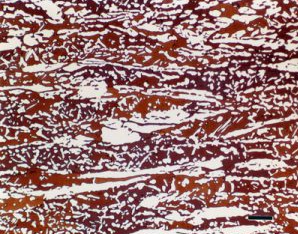

STAINLESS STEEL ALLOYS

Many materials fall into the category of stainless steel alloys, including austenitic, martensitic, duplex, ferritic and other types of stainless steels. These are most easily NDT tested in both tubular form or in bar stock form (long constant cross section).

INSPECTING STAINLESS STEEL WELDED TUBE

MAC’s Minimac® II eddy current instrument is a high performance yet affordable, compact tester that is used to inspect a range of tubing, including stainless steel, copper, cold drawn welded, and seamless.