GENERAL RELEASE MARCH 2020

Magnetic Analysis Corporation provides advanced inspection technologies, including eddy current and ultrasonic techniques, for accurate testing of small-diameter, high-performance tubes used in critical applications such as aerospace and nuclear industries.

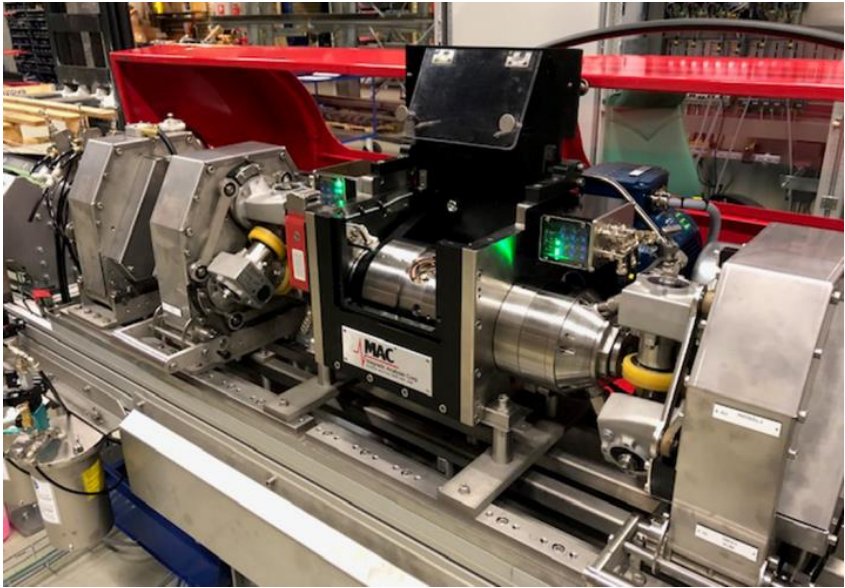

MAC’s ultrasonic instruments detect core flaws, ID/OD defects, wall thickness variations, and dimensional measurements. The Echomac® UT 25mm rotary provides 100% coverage at high throughput rates for thin-wall products ranging from 5 to 25mm in diameter. It is especially suited for demanding applications requiring high performance, such as tubular products for nuclear and aerospace installations. Used with MAC’s Echomac® instrumentation, the rotary system ensures superior inspection of ID/OD, longitudinal and transverse flaws, wall thickness, and dimensional attributes like eccentricity and ovality. The Echomac® FD-6A electronics has received GE qualification for P3TF31 Class A & B and P29TF82 Class A & B, meeting typical nuclear and aerospace requirements. The FD-6/6A software can also be equipped with a C-scan for simplified test result analysis.

With an overall length of 630mm, the 25mm rotary allows seamless upgrades for inspection lines with limited space. It successfully tests wall thicknesses down to 0.3mm and tubes as short as 1 meter. Key features include a transformer design for improved signal-to-noise ratio, a wide range of selectable band-pass filter settings, precise thickness resolution (1 μm), and excellent repeatability and reliability. Operating at 8,000 RPM, it provides optimal results with FD-6/6A electronics or existing instruments for line upgrades.

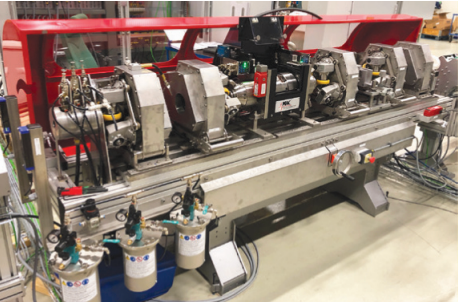

MAC’s 20mm Rotomac® eddy current rotary efficiently detects longitudinal surface flaws such as seams and laps at speeds up to 18,000 RPM. It delivers highly sensitive non-contact testing with superior results on tubes ranging from 2 to 20mm (0.0787” – 0.7874”) in diameter. Enhanced distance compensation corrects for material misalignment, while a small bearing hub ensures precise probe rotation—crucial for testing diameters as small as 2mm. A dial-in guide allows easy simultaneous adjustment of both test probes, and quick twist-on bushing holders add to the rotary’s user-friendly design. The Rotomac® operates with MAC’s Multimac® eddy current instrumentation, making it ideal for straight and cut operations as well as continuous processes like drawing, spring-making, and parts forming. It can be installed in-line with straighteners or off-line in a separate test station, inspecting ferromagnetic, non-ferromagnetic, and austenitic materials.

MAC’s experienced engineers provide expert guidance on eddy current, flux leakage, and ultrasonic test solutions, including:

- Phased Array systems for weld zone profiling and defect detection in ERW tube

- Multi-test systems for OCTG pipe up to 500mm in diameter

- Comprehensive nondestructive testing solutions for tube producers

With over 90 years of experience, MAC continues to be a trusted provider of nondestructive test equipment and systems for tube, bar, and wire manufacturers, ensuring a thorough understanding of customer inspection needs.

Echomac® 25mm ultrasonic rotary on a test bench for inspecting small diameter material.

Rotomac® 20mm eddy current rotary for detecting longitudinal surface seam type defects in small diameter tube.