WIRE FORMING TECHNOLOGY INTERNATIONAL FALL 2019

Quality Checking Fixtures & Gages

Aaron Waldie, Sales Manager at Crum Manufacturing, Inc., Waterville, OH, USA, says, “Crum Manufacturing, Inc. has been a trusted supplier of Quality Checking Fixtures and Gages for more than 35 years. Crum Manufacturing specializes in custom quality check Fixtures and Gages for many different products across a wide range of industries including automotive, aerospace and defense, industrial, appliance, plastic injection molding, etc., just to name a few.

“The gages we make help quickly and accurately check many different parts such as wire forms, metal stampings, formed tube and pipe, plastic molded parts and all types of assemblies.

“Crum uses a variety of different materials for our gages depending on the part being checked and your company standards. We have vast experience with all types of gages and fixtures from regular check fixtures to GD&T gages to fully automated assembly gages. Stamp and Trim fixtures are also a specialty of ours. We utilize REN Board material or metal gages either with aluminum or stainless steel.

“Our team has found that our REN Board material is perfect for wire forms and springs. It is a polyurethane-based board designed for CNC machining of production-grade checking and assembly fixtures. REN Board is not only very durable, it is very lightweight and much more cost-effective than a standard metal gage. This makes it a perfect fit for lighter weight parts like springs and wire forms.

“Crum Mfg. is a privately owned, third-generation family business. A few things that set us apart from our competitors are our quality, our responsiveness, and our flexibility. We are very willing to work with our customers on lead times and pricing in order to grow and maintain the relationship. Crum is ISO 9001:2015 certified and we pride ourselves on delivering nothing but top-quality products to our customers.

“Crum Mfg. would welcome any opportunity to be considered a new supplier for you. Feel free to reach out to us directly via our website.” www.crummfg.com

Equipment for Nondestructive Testing & Alloy Wire Testing

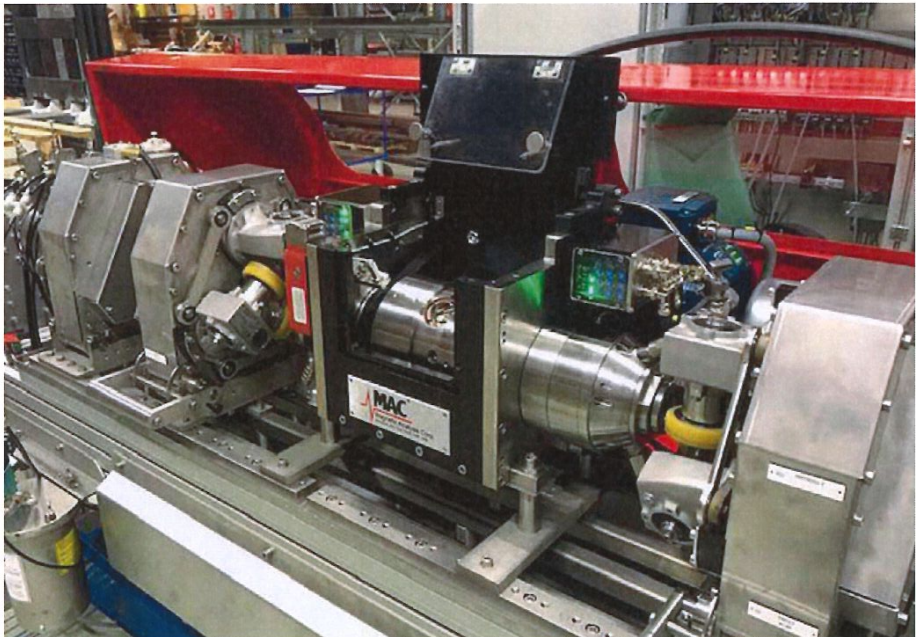

Information from Magnetic Analysis Corporation (MAC®), Elmsford, NY, USA, says, “Magnetic Analysis Corporation (MAC) provides instruments, systems, and solutions that are recognized the world over as the standard for nondestructive testing.

Technical research, product development, and innovative approaches have been the hallmarks of the company for more than 90 years.

“At the core of Magnetic Analysis Corporation’s comprehensive portfolio of material handling and NDT equipment options are Eddy Current, Magnetic Flux Leakage, and Ultrasonic testing equipment. Many of these instruments and systems are well suited for testing applications during production, in either on-line or off-line versions.

“Three facilities form the backbone of the company: MAC’s ISO 9001:2015-certified manufacturing and engineering facility in Elmsford; a manufacturing and ISO/IEC 17025:2005 laboratory-certified plant in Boardman, OH, USA; and Magnetic Analysis Nordic’s manufacturing plant located in Östersund, Sweden.

“MAC also has the unique capability to provide quality service throughout most of the world. The MAC global network provides the industry with a team of industry experts, highly trained engineers, and seasoned field representatives who can understand your testing requirements.

“Collaboration with the client is an essential part of MAC’s process. What truly sets MAC apart from other NDT companies is MAC’s focus on 100% customer satisfaction. MAC partners with its customers to determine their needs and then configures the product solution that will work best for them. MAC also offers short- and long-term operating leases on most standard test systems.

“MAC also points out that testing stainless steel wire like A-286 alloy, often used for fabricating fasteners for high-temperature applications including jet turbine engines for aerospace and turbocharged high-horsepower engines in automobiles and trucks, can be challenging. But MAC’s high-speed eddy current Rotomac® 20mm rotary can provide accurate, reliable inspection to find cracks that may form or enlarge after annealing.

“Applied to marginally straightened wire, so it can be tested but not enough to excessively cold work and change the mechanical properties, the 20mm Rotomac has the capability to adapt carbide wire drawing nibs as bushings to hold the wire centered under the test probes. The Rotomac’s Distance Compensation helps in compensating for a lack of straightness during testing, which is a frequent problem. Also, a small bearing hub produces a much more precise rotation of the test probes as they rotate around the mechanical center, an important factor in testing diameters as small as 2mm.

“The A-286 alloy is also very difficult to eddy current test because of its poor conductivity and lack of magnetic properties, but the company’s Z-probe produces a much better signal-to-noise ratio than standard null probes. The company’s MultiMac® eddy current electronics are used with the Rotomac Rotary.”

www.mac-ndt.com