Standards: AMS 2164, AMS 2631, NAS 824, MIL-T-16420K, TS9074-AS-GIB-010/271

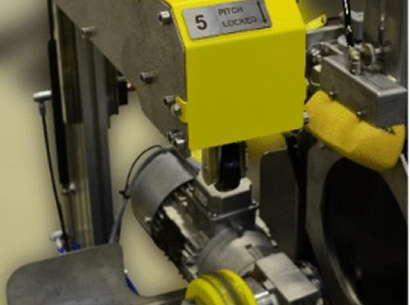

In 2022, MAC® expanded its capabilities with the acquisition of TacTic®, formerly a division of Laboratory Testing Inc. This strategic move allowed MAC to broaden its product offerings for automated and specialized “spin-the-tube” ultrasonic immersion test systems—engineered to detect both surface and subsurface defects(longitudinal and transverse) in tube and bar.

Long recognized as a cost-effective choice for metal producers and inspection labs for their ability to achieve the highest performing ultrasonic examinations over a wide diameter range of materials. Only TacTic® offers a single system capable to test from 1/8" to 6" making them ideal for processing material with frequent diameter changes. TacTic® has earned a reputation for the highest testing performance coupled with flexibility, reliability, and ease of use.

Now, after three years of research and customer feedback, MAC proudly introduces the second generation of TacTic® test systems-bringing enhanced accuracy, improved operation, and better material handling to the proven original design.