Authored by Phil Meinczinger, BDM

STAINLESS STEEL WORLD-AMERICAS JUNE 2019

With the ever-increasing demand for small diameter stainless and specialty bars, tubes, and wires for critical applications such as automotive, medical, and aerospace, specifications are becoming more restrictive, therefore placing extreme pressure on the productivity of nondestructive testing (NDT) equipment. This presents a unique challenge to achieve higher test requirements without sacrificing production.

In the past there has been a rift between production and quality, but with advances in technology and education, both quality and production can be satisfied.

By Phil Meinczinger, Magnetic Analysis Corporation Business Development Manager

Choosing the correct method for stainless bar, tube, or wire

There are generally two accepted methods for testing small diameter stainless bar and tube material: ultrasonic and eddy current.

Ultrasonic technology is widely used on stainless material with diameters as small as 5 mm for surface and/or internal flaw detection, and dimensional testing. With the new, higher test requirements, transducer selection and material handling have become extremely important. Transducer selection will vary based on the size and type of material, as well as the flaw length required to be detected at a given throughput speed.

For material less than 5 mm in diameter, eddy current NDT is a proven method for surface inspection, which can achieve high inspection speeds. Coil type and material stability are very critical.

The ultrasonic method

Spin the bar or tube

The first approach for the ultrasonic inspection is a ‘spin the bar or tube’ method. In this method, the stainless bar or tube is rotated past a series of transducers that are located in a stationary water box.

This system gives users the ability to inspect a large range of diameters with the same unit, resulting in a lower cost inspection system, and a set-up time of approximately 20 minutes. Set-up includes manipulating the transducers and changing the rotation speed and drive roll helical pitch for the different test product sizes.

The disadvantage to this method is slow production speeds, with a range of 10 feet per minute or less. Smaller diameters have a tendency to be unstable when spun quickly, therefore rotation speeds must be lower, which will then result in lower throughput speeds to maintain full test coverage. With today’s notches as short as 1.5 mm in length, and as shallow as .05 mm in depth, the need to detect transverse indications also limits the throughput speed of a spin the product system.

For companies producing small quantities of stainless bars and tubes in a large size range, however, a spin the tube system may be a suitable solution.

Rotary ultrasonic system

Producers and suppliers of smaller diameter stainless tubes and bars must find a different approach that will allow for higher production rates, without the risk of sacrificing defect detection.

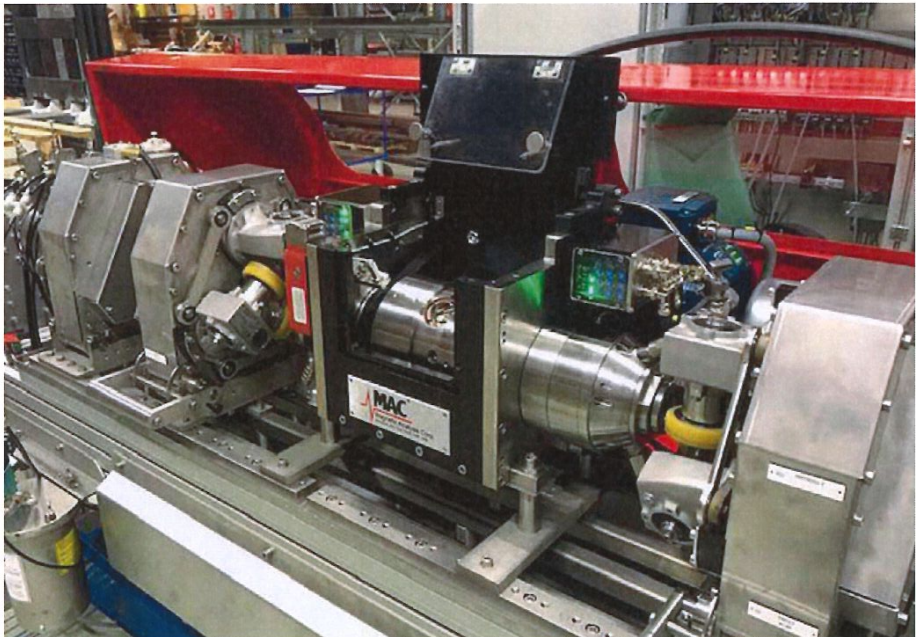

A solution to meet these tighter specifications at the required high production speeds, is a rotary ultrasonic system. This type of system, especially for material in the 5 to 25mm range can meet both the defect detection level required, and a high throughput speed. This approach for this size range has up to eight highly-focused transducers located in a rotating water box, which spins up to 8,000 times per minute.

For stainless tubes, a typical transducer configuration would be four shear wave transducers looking clockwise, and four shear wave transducers looking counterclockwise for ID and OD notch detection, at speeds of up to 100 feet per minute.

For small diameter stainless bars, the general configuration would be two shear wave transducers clockwise, two shear wave transducers counterclockwise, two devices for forward and reverse transverse, and two transducers set at normal incidence for internal indications.

Taking advantage of a rotary system’s speed of inspection, a rotary can displace three or more spin the bar or tube systems. With the shortage of qualified operators, one person can produce the same amount of high-quality material as three operators. Set-up times are approximately the same for both systems, and the only additional step required for a rotary is replacing internal bushings and glands, which must be changed for each size, requiring an additional two minutes of set-up time.

The only disadvantage of this system is the cost. The rotary system has a premium cost of approximately 25% more than a spin the product system. The cost of ownership is approximately the same for both spin the product and rotary ultrasonic systems. Repeatability is also a critical consideration. However, if the units are used as required for a certain flaw type and level, both systems will meet repeatability requirements.

Electronics

There are three main considerations when choosing ultrasonic instrumentation:

Capability: The electronics must be capable of performing in conjunction with the test system, in order to achieve the high sensitivity required to meet today’s tight test requirements, and to have a linear response throughout its range, while still having the ability to expand for future needs.

Data retention and storing set-up parameters: This is becoming an increasingly vital part of any NDT system. Today’s units are generally computer-based, therefore both of these requirements can be met. Data can be stored locally with either ‘A scan’ or ‘C scan’ presentations, along with all the raw data. This includes a time stamp so that any indication can be located with time/date, and flaw position. Equipment settings can be stored locally, or the unit can be integrated with the local network, so data can be reviewed at a remote location.

Operator interface: This feature is generally overlooked. However, having an intuitive operator interface is extremely important. The better the interface, the quicker size changes can be made by the operator, which leads to an increase in productivity.

NDT improves quality and profitability

Quality cannot be inspected into stainless tube bar or wire, but with the proper use of these NDT solutions it can identify sources of non-compliant material and, with the proper feedback, quality can be increased, scrap reduced, and profitability increased. Choosing the correct NDT system can seem like an insurmountable situation, but with an understanding of the strengths and weaknesses of each discipline, the correct decision can be made for the application.

Material handling

Both the spin of the product and the rotary method require accurate material handling.

For a spin the product application, a series of offset rollers rotate the product, and move it forward past the transducers in the stationary water box. This limits the throughput speed of small diameter material due to material instability, and material surface lubrication. If there is residual lubricant from previous processes, they may cause the material to slip on the rollers as the product is spinning, requiring an additional operation to clean the material surface.

For an ultrasonic rotary system in the 5 to 25 mm range, a 90° V belt system is the recommended method for transporting material. With this type of system, the instability in the smaller diameters is eliminated, and any residual lubricant is of no consideration for handing since the material does not rotate.

Eddy current on small diameter stainless wire products

Eddy current technology has been widely used in the detection of flaws in small diameter stainless wire products, and can be an economical solution for inspecting wire. This method can be used for surface inspection of material down to 0.2 mm diameter, and defects as small as 0.5% of the product diameter can be detected, depending on the surface condition. Eddy current systems can be used for inline production installations, and can also be used in conjunction with an ultrasonic system on larger material to provide a supplemental test.

With speeds reaching or exceeding 600 meters per minute, these high-speed applications also have their own unique situations.

Electronics selection

The electronics must be capable of processing data at the higher speeds. All eddy current systems are speed-sensitive, therefore an encoder must be placed on the line to give speed information. The electronics must be capable of accepting this speed information and automatically adjust the filters, in order to compensate for speed variations.

Coil selection

Coils in this application are of a higher frequency, generally in the 1-8 MHz range. Coils for larger diameter material need to be in the 2-100 KHz range. The frequency selection is critical in order to ensure proper flaw detection at the higher production speeds.

Containment

Control of the material undergoing testing is of the utmost importance because an out-of-control wire at these speeds can have severe consequences. This is generally done with guide rollers before and after the coil, along with the use of an internal coil bushing to protect the sensor. The guiding system and bushings serve two functions, one is to contain the wire, and the second is to center the material in the coil.

Centering

Centering is very critical when testing. This is true for eddy current, as well as ultrasonic systems. If the material undergoing testing is not centered, defect detection will not be repeatable. During eddy current testing the sensitivity will vary as the distance from the coil varies. The greater the distance, the higher the sensitivity that is required. Therefore, if the material is not centered in the coil, the flaw detection will vary, depending on whether the material is closer or farther from the coil.

Data collection

As stated previously, the eddy current coil is usually installed in a wire drawing production line consisting of a draw block, which draws the wire through the test, and into a coiling operation. Data received from the eddy current coil has two functions. The first is to give immediate feedback to an operator. This way, flaws can be detected in process, and adjustments can be made, therefore avoiding continuous production of flawed material. The second is to use wire grading software to determine the quality level of the material being produced, so that coils can be evaluated for different applications.