WIRE & CABLE TECHNOLOGY INTERNATIONAL MARCH 2019

by:

Jean R. Gould, Marketing Manager

Magnetic Analysis Corporation

103 Fairview Park Drive

Elmsford, N.Y. 10523-1544 USA

www.mac-ndt.com

Capable of detecting the very small mandated notches dictated by the aerospace, nuclear, and medical industries.

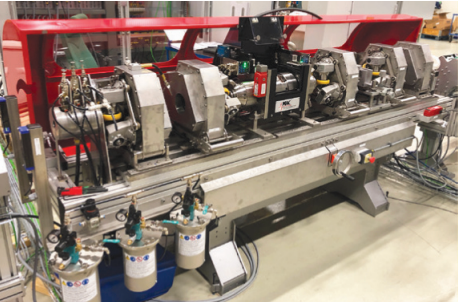

Magnetic Analysis Corporation (MAC) has recently supplied an ultrasonic test system to a major finishing processor of bars for medical components. Featuring MAC’s new top-of-the-line 25 mm Echomac® UT Rotary, Echomac® FD-6A electronics, triple pinch bench, and a customized belt conveyor and sorting system, this inspection apparatus is capable of testing to the highest quality levels, detecting the very small mandated notches dictated by the aerospace, nuclear, and medical industries.

The new Echomac 25 mm Rotary provides 100% coverage at high throughput rates, ranging up to 200 fpm, depending on customer requirements. Features include a transformer design, which ensures improved signal-to-noise ratio, enhanced bandwidth, zero channel cross-talk, 8000 RPM running speed, precision test blocks, and transducer holders.

Other advantages include convenient adjustment of the transducer angle, fast changeovers, and control by an easy-to-use PLC with a touch panel. Bars as short as 1 m can be successfully tested, and the 630 mm overall length of the rotary also allows for ease of installation in existing inspection lines that need upgrading.

The Echomac FD-6A software includes a C scan for ease of test result analysis. Special mechanics are provided to handle the small diameters with maximum protection for the surface of the material under test, and the triple bench is provided with a Lexan hood to ensure operator safety while allowing the test to be visually monitored.

MAC’s Echomac FD-6A instrumentation is also GE qualified to meet certain typical requirements for critical applications such as nuclear and aerospace. The 25 mm Echomac joins MAC’s line of ultrasonic rotaries that now handle material ranging from 5 to 500 mm in diameter.