INTERNATIONAL METAL TUBE OCTOBER 2019

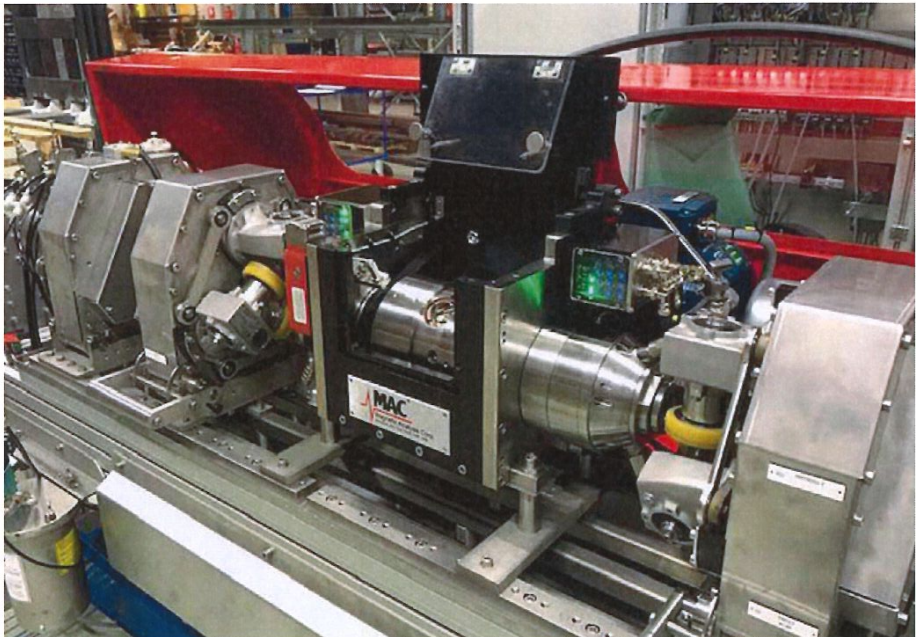

Magnetic Analysis Corp. has just delivered a single channel Multimac eddy current off-line test system designed to meet ASTM 999 (American Society for Testing Materials) specifications for testing welded stainless steel pipe.

The test will be inspecting 6 different diameters, ranging from 2 3/8" up to 8 5/8" (60mm to 219 mm), an unusually large spread of sizes for one test system. The pipe, which is destined for challenging environments, is characterized by high strength and corrosion resistance.

To ensure the pipe meets the required specifications, the system is designed to detect 3 or more drilled through holes, not exceeding specified diameters, in the test standard. The holes must be equally spaced circumferentially around the pipe, and longitudinally separated to allow distinct identification of the signal from each hole.

The test system includes a "V" roll welded bench with dual Pinch Stands, and an eddy current air operated saturation test coil with triple front and rear guide rolls to ensure accurate positioning of the pipe during the test. The DC saturation level, controlled by the Multimac software, is used to minimize electronic noise which may occur when testing stainless material. The test coil is mounted on a slide mechanism to allow access during maintenance.

MAC's MultiMac instrument includes screens that clearly display defect signals, thresholds and other data. Setups can be easily stored and recalled, and data printed and transferred.

50% reduce downtime from Mitsubishi Heavy Industries America

Mitsubishi Heavy Industries America Corrugating Machinery Division launches Remote Assistance Augmented Reality Program

The Corrugating Machinery Division of Mitsubishi Heavy Industries America (MHA) launched its new Remote Assistance Augmented Reality Program as the latest enhancement to its industry-leading customer service support at CorrExpo (Booth #601, Colorado Convention Center, Denver, October 14-16).

Mitsubishi Heavy Industries America (MHA) is a leading supplier of corrugating and box-making machinery.

CorrExpo attendees can experience the new Remote Assistance Augmented Reality Program at Booth #601, which is forecast to reduce customer downtime by 50%.

The new Remote Assistance Augmented Reality Program is designed to allow plant managers, technicians, and engineers to quickly and efficiently share issues in real-time from their facilities, allowing MHA technical support staff to see and resolve machine issues and assist in troubleshooting.

The program allows MHA technical experts to draw and annotate on their device, text on the screen, and capture pictures or video for future reference.

"The industry’s best customer service just got better, and we’re excited to share this latest service enhancement with our customers across North America. Our commitment to our customers continues full speed ahead," said Darold Phillips, Vice President, Service, MHA Corrugating Machinery Division.

"Through our intuitive app, we can see what the customer is seeing and more quickly resolve their challenges, speeding up recovery time and frequently eliminating the need for a time-consuming, on-site visit."

The Remote Assistance Augmented Reality Program was developed in conjunction with SCOPE AR, a global leader in developing augmented reality solutions and products for industrial clients focused on field maintenance, manufacturing, and training.