WIRE AND CABLE TECHNOLOGY INTERNATIONAL MARCH 2023

Jean R. Gould, Marketing Manager

Magnetic Analysis Corporation (MAC)

103 Fairview Park Drive

Elmsford, NY 10523 USA

www.mac-ndt.com

Increasing demands for high-quality steel rod and bar requires effective nondestructive (NDT) testing to ensure producers can meet their customer’s needs. As specifications become ever more stringent, NDT technology is consistently evolving new capabilities, adapting to new conditions and improving integration with mill operations.

Magnetic Analysis Corporation, a designer and producer of NDT instruments and systems for 95 years, is supplying a comprehensive automated test system to a precision cold finishing specialty steel mill that specializes in close-tolerance round bar products. This precision cold finishing specialty steel mill must be capable of providing the company’s customers with clean, round and straight precision round bar that is ready to be used as bar stock for manufacturing finished parts such as bearing shafts and other critical parts. And to do this, the company relies on accurate inspection using nondestructive testing technologies.

Eddy Current & Ultrasonic NDT Technologies

The MAC® system, which will be supplied to the company, incorporates both eddy current and ultrasonic NDT technologies, for use in testing centerless ground stainless steel bars ranging from ¾" to 3.5" (19.05 to 88.9 mm) in diameter at speeds up to 150 fpm. Eddy current rotary testing is the method of choice for detecting long seam type surface defects in wire and bar.

MAC’s Rotomac® eddy current rotary spins test probes around the bar at 3000 rpm as it passes through the tester. The eddy current test will be testing for surface flaws down to 0.125 mm in depth.

Following the eddy current test, the bar passes through MAC’s Echomac® ultrasonic rotary, which conducts a 100% volumetric test to detect core internal flaws. The rotary spins UT transducer elements around the bar. These elements produce high-frequency sound waves, which are transmitted into the bar as it passes through the test. The unique seal-less rotary design reduces maintenance and downtime by minimizing problems that result from debris on the bars contaminating the water system, which supplies the necessary couplant for the UT inspection.

Automated Seamless Materials Handling System

However, a comprehensive test system to inspect round bar needs more than instrumentation. The test system should be

incorporated with an automated seamless material handling system that has been engineered to feed, convey, separate and output the bars into the correct pockets for bundling without inflicting damage to the bar finishes, back-ups, jams and similar problems.

The system to be supplied to the company is 32 m (105') long, overall, with input tables, stop arms and pneumatic release mechanisms that are designed to retain the bars on the rack, and then lift and carefully release the bars one by one onto the channel roll sections that convey the material through the testers.

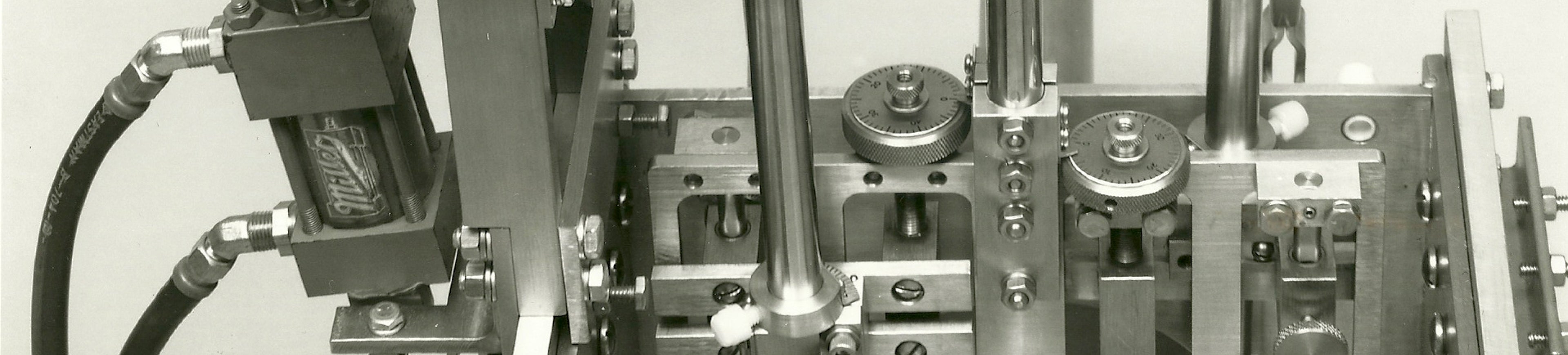

On the output side, automatic sorting of defective bars takes place. Acceptable bars are automatically aligned and fed to an accumulation table where they are held until the release mechanism activates, and they drop into the accept pockets for bundling. Both testers are mounted on a triple pinch bench, which guides, centers and drives the bars through the test.