STAINLESS STEEL WORLD-AMERICAS JUNE 2023

Industrial heat exchanger users, aerospace, medical, and some military applications require the highest quality materials and also demand high inspection levels for long intermediate products (wire, tube, and bars). Surprisingly, automotive materials can also require the highest quality because defects in safety-critical components or parts integral to engine lifetime or fuel systems can lead to huge expenses.

Detecting Defects

A common concern for stainless bar suppliers is ensuring that customers receive seam-free material. Bars are generally rolled from billet stock, and the resulting hot-rolled product can have elongated defects from the original billet material, appearing as seams. Additionally, the hot rolling process can introduce rolling mill under-fill or over-fill stages, leading to laps or seams.

The final sizing process can remove surface seams if some surface removal is done. This processing is proprietary to each manufacturer, but the finished product may benefit from a final inspection of the raw material surface. The use of non-destructive testing (NDT) becomes a cost-benefit consideration.

Stainless tubes made by extrusion or welding require at least encircling coil eddy current (EC) testing, but may also need full-body ultrasonic testing on 100% of the supplied tubes, based on ASTM requirements tailored to the application.

Some final products, such as finished gears and nozzles, can greatly benefit from internal bar inspection, often using full volumetric ultrasonic inspection. This method detects both surface and internal defects like voids, porosity, segregation, non-metallic inclusions, and cracks. Many of these originate from the billet, which, after hot rolling and drawing, may process defects into needle-shaped inclusions or voids.

One reason for improved product reliability is the use of automated ultrasonic inspection on 100% of critical quality bar stock before final product assembly. However, simply using NDT is not enough for extremely high quality. NDT determines product or process quality, but consistent quality requires a manufacturing process designed to produce high-grade material, including thorough examination of bar and tubing production methods and the use of high-quality raw materials.

For stainless steel, continuous material lends itself to automated, high-throughput inspection. Material can be inspected as part of the coil process or in finished or semi-finished lengths.

Spools of small-diameter wire can be tested to a high-quality level, but the entire coil must be rated since rejecting a coil over a single defect is costly. Finished bars can be tested economically, rejecting only those that exceed a predefined defect level.

Eddy Current Testing

EC inspection can be performed using a simple encircling coil without speed limitations. This test coil can be strategically placed in the production process. When testing and shipping long coils of wire, in-process testing can grade spool quality.

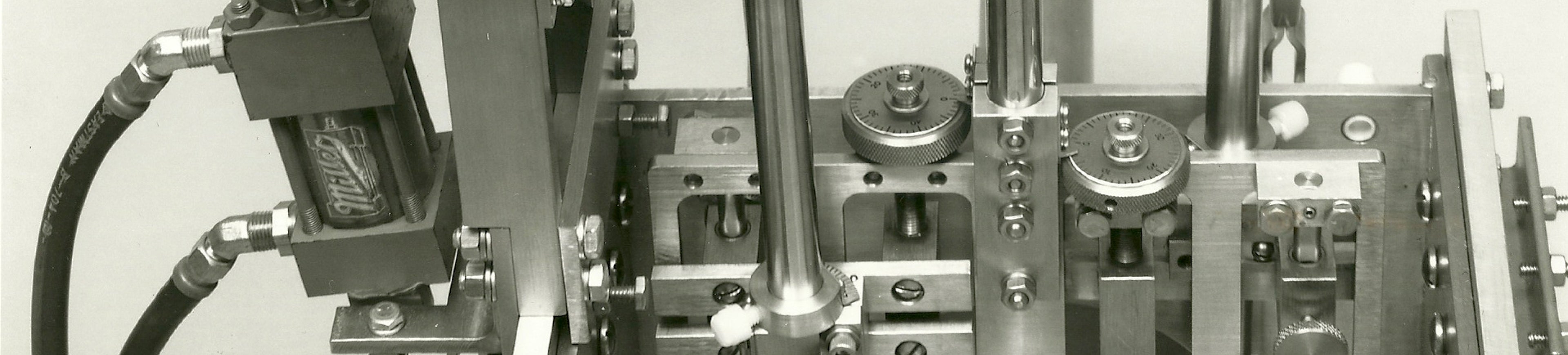

For larger diameter materials where seam defects affect final product quality, a spinning EC probe inspection can be used. Since spinning probes create a helical coverage pattern, the test plan must ensure 100% surface coverage or be designed to detect defects of a minimum length. Sometimes, test standards include an artificial notch with a predefined rejectable notch length and depth.

If internal inclusions or centerline segregation pose a risk, ultrasonic testing should be used. Some stainless steel surface seams are better detected using ultrasonics for extremely high quality.

A simple encircling coil inspection requires centering the material to ensure uniform surface testing. Centering must be controlled within 1% to 3% of the product diameter for repeatable results. Small-diameter material can be centered economically using slightly oversized draw dies. For larger diameters, centering rolls and oversized guide bushings are necessary. A triple-roll arrangement provides a cost-effective constant centerline configuration.

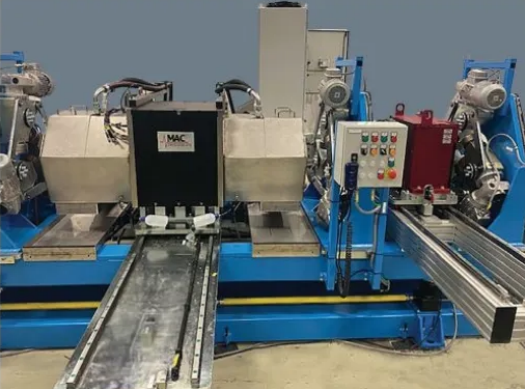

Finished stainless bars up to 4” in diameter benefit from EC NDT, typically using a rotary device that spins EC probes around the bar to detect surface defects. The producer determines if defect-free material (zero seam depth) is required or if the customer will perform further material removal. If defect-free material is needed, EC testing is conducted before final processing, detecting defects at a level such as 0.15mm, followed by grinding to remove that depth.

Many producers remove surface material before final processing, ensuring delivered material is free of surface defects exceeding the customer’s removal depth.

Ultrasonic Testing

For the highest quality materials, ultrasonic testing or a combination of ultrasonic and EC methods is needed. Ultrasonic inspection detects internal, surface, and subsurface defects. Customers specify bar quality levels based on the final product’s requirements.

A common specification is AMS-STD-2154, with a similar ASTM standard, ASTM-E2375. Quality levels range from AAA (highest) to C. Some users specify testing with a side-drilled hole of a particular diameter and length, while others require a flat-bottom drilled hole (FBH or FBDH), used for the highest quality materials.

Various ASTM-mandated inspection practices exist for stainless tube inspection based on application. European manufacturers follow ISO/EN standards.

The growing demand for high-quality small-diameter bars and tubes has led to the development of small-diameter ultrasonic testers, capable of inspecting up to 25.4mm. Common sizes range from ¼” to ¾”, requiring high inspection speeds to meet production volume needs.

Stainless bar producers are increasingly using phased array ultrasonics for easier NDT station setup, though it sacrifices some flexibility.

Conclusion

The demand for high-quality, defect-free stainless steel components and tubes in industries such as chemical, power, aerospace, medical, military, and automotive necessitates reliable NDT methods. EC and ultrasonic inspections detect surface and internal defects in stainless steel tubes, bars, and wires. These inspections ensure the required quality level, and additional processing, such as grinding, may be needed to meet specifications.

ASTM and AMS-STD standards often mandate artificial notch test samples to validate inspection quality. In some cases, marginally rejectable natural defects supplement artificial notches, verifying the effectiveness of the inspection process.