WIRE DRAHT APRIL 2021

Magnetic Analysis Corp., (MAC) joins in congratulating WIRE on its 70 years covering the growth of the wire industry. A designer and manufacturer of nondestructive test systems, MAC was founded in 1928 and since then has made important contributions to testing technology for wire, cable and bar.

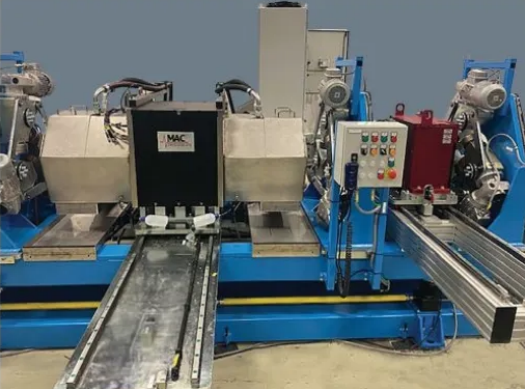

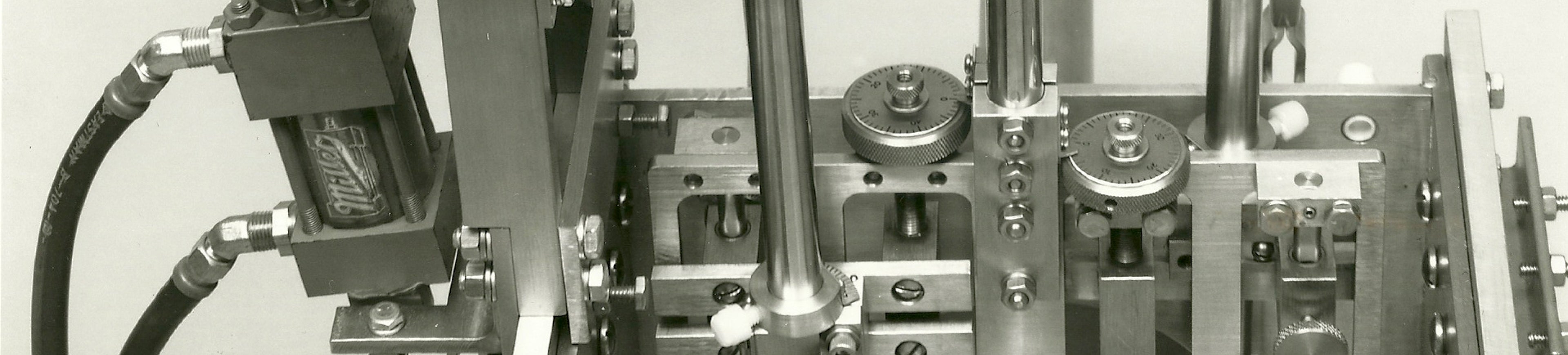

MAC’s earliest test systems were based on electromagnetic technology which detected changes in permeability. This led to the first successful test of cold drawn steel rod for cracks in 1934 at Union Drawn Steel in Beaver Falls, Pennsylvania, US. As the market for wire and rod has grown in the years since, so too has the need for ever more accurate methods of testing. In 1953 MAC introduced eddy current technology in the U.S. which measured the material’s conductivity instead of permeability. This led to more reliable detection of short surface defects, including in copper, brass, stainless steel and other non-ferrous metals. In 1959, MAC introduced the Rotomac® rotary probe tester for high-speed detection of longitudinal, continuous defects in wire and rod, including spring wire. Today, nondestructive eddy current technology is often a preferred technology for testing magnetic and non-magnetic wire during production. MAC’s “MultiMac” and “Minimac” test systems are inspecting for flaws, seams, inclusions, continuity, and locating welds and splices, in cold drawn wire, insulated cable, and wire as small as 0.0035" diameter, at speeds up to 18,000 RPM in plants throughout the world.

Installation in China

At a continuous cast copper rod mill in China, a Multi Mac eddy current tester is currently installed just before the coiler, but after the rod is produced and drawn down to smaller diameters. The tester assesses grade, using MAC’s Grading Software, and detects magnetic inclusions, using a MID test coil. The Grading Software provides a convenient, efficient means of automatically categorizing the quality level of individual segments and entire coils of wire, rod, and bar during production. The customer can customize the defect types, each based on a specific threshold gate, specify the maximum number of defects for each grade level, and configure reports. Surface defects as well as inclusions are detected and categorized. In this instance, rod graded higher is drawn down to even smaller diameters. Lower grades are not drawn down as much to avoid problems with breakage in the wire which could end up causing a disruptive downtime to rethread the drawing machine.