EUROWIRE JULY 2021

Magnetic Analysis Corp (MAC), founded in 1928, offers a full range of eddy current test instruments and systems for detecting surface and sub-surface defects, including laps, slivers, and cracks in non-ferrous and ferrous wire and bar.

The line of MultiMac® and Minimac® versatile eddy current instruments are used in a broad range of applications in wire mills during production. Minimacs can inspect welding wire, including flux core wire, detecting missing flux as well as flaws in the wire itself. Checking continuity and locating welds in single and multi-conductor insulated wire and cable are other applications.

Using a magnetic inclusion detection (MID) option, the Minimac is also effective for detecting magnetic inclusions in non-magnetic products. For seam-type, longitudinal surface defects, and laps in cold-drawn wire, MAC’s Rotomac® line of rotary probe eddy current testers includes models for high-speed production, operating at up to 18,000 rpm on wire from 2 to 20mm (0.0787" to 0.7874") in diameter, as well as the Rotomac RM for testing wire and rod from 3 to 25mm in diameter in slow throughput lines, such as in parts forming.

A wire alloy producer is using a MultiMac single-channel eddy current tester to inspect zirconium, copper, and beryllium copper alloys ranging from 0.838 to 6.35mm (0.033" to 0.25") in diameter. The test is part of the finish inspection, detecting surface defects in plating, sub-surface anomalies in bonding, and inclusions in multiple layers. A noise-canceling test coil improves performance by minimizing noise from mechanical vibration in the wire that could otherwise interfere with the test.

In another application, at a continuous cast small-diameter copper rod mill in China, a MultiMac eddy current tester is installed just before the coiler, after the rod is produced and drawn down to smaller diameters. The tester assesses grade using MAC’s Grading Software and detects magnetic inclusions using a MID test coil.

The Grading Software provides an efficient means of automatically categorizing the quality level of individual segments and entire coils of wire and rod during production. Customers can customize defect types based on specific threshold gates, specify the maximum number of defects for each grade level, and configure reports.

MultiMac eddy current testers are also being used to inspect continuous copper wire rod, used as feedstock in wire copper strip production. The rods range from 0.5 to 3.5mm (0.01968" to 0.13778"), and the test identifies external defects such as scratches, dents, and gaps at speeds up to 20m/s.

Magnetic Analysis Corp

www.mac-ndt.com

Wire Tooling

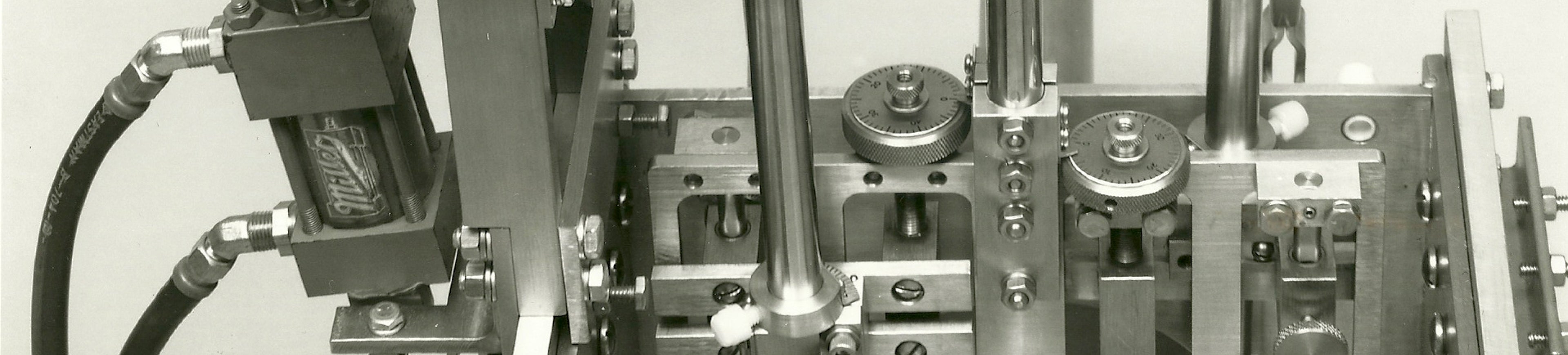

Sjogren Industries, Inc., founded in 1927 by Oscar Sjogren, designs and manufactures customized solutions for the wire tooling trades, delivering machinery, tooling, and accessories to a worldwide customer base. The firm continues to introduce enhancements in wire straightening assemblies and components that provide efficiencies and increased productivity.

Sjogren has a highly skilled workforce, with machinists averaging more than fifteen years of experience in custom manufacturing. This expertise, combined with lights-out manufacturing capabilities, offers efficiency and reduced waste.

In its climate-controlled facility, Sjogren employs duplicate tooling centers and has the ability to produce specific fixtures and tooling for customer requirements. Nothing is outsourced.

As a supplier of wire straighteners, straightener rolls, and wire tooling equipment, Sjogren has innovated with its marker groove technology, which delivers precision and reduces wear and downtime. The company has also developed a turnkey product maintenance program for its grooved roll customers.

To help customers select the proper wire-straightening device, Sjogren offers ten different series of straightener designs to meet all requirements. Each series has a unique design and specific features.

For in-line drawing systems, the company provides models with quick-release handles, quick-release tilt rails, inch and metric measurements, mounting plates for vertical and horizontal requirements, individual roll adjustability for quick adjustments or replacements, and control of cast and helix.

For mesh machines, Sjogren offers narrow-line design straighteners for applications requiring multiple straighteners in limited space. For machine builders, the company customizes units to fit specific applications and provides measuring devices to monitor and adjust roll depth.

Products Available from Sjogren Industries:

- Wire straighteners

- Grooved rolls

- Wire pullers and wedge grips

- Wire guides

- Magnetic brakes and clutches

- Testing machines

- Handling machines

Sjogren Industries also provides contract manufacturing services for the industry.