PRODUCTION COMPARATOR VI

Production Comparator VI is a Windows® based test instrument that uses low frequency electromagnetic techniques to inspect magnetic materials for variations in physical characteristics such as alloy, heat treatment and case depth. I

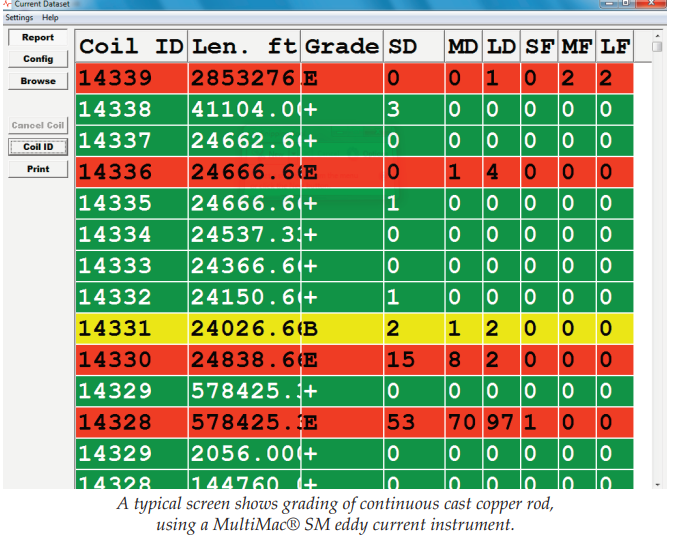

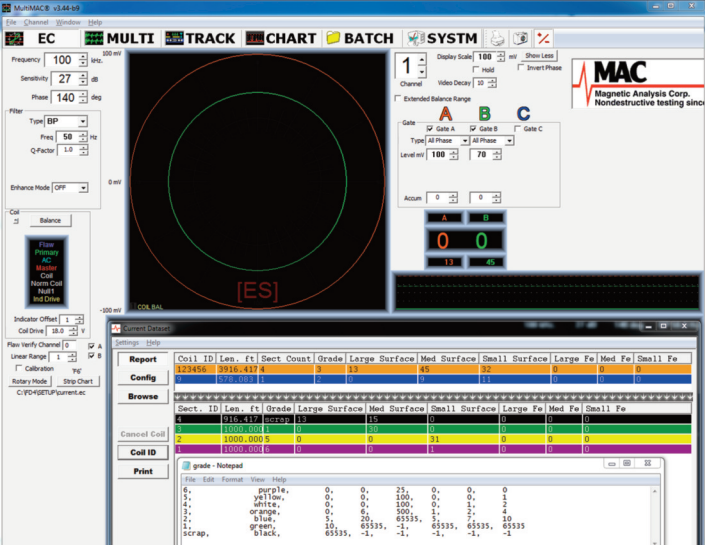

QUALITY GRADING SOFTWARE

For Customized Grading of Wire, Rod or Bar

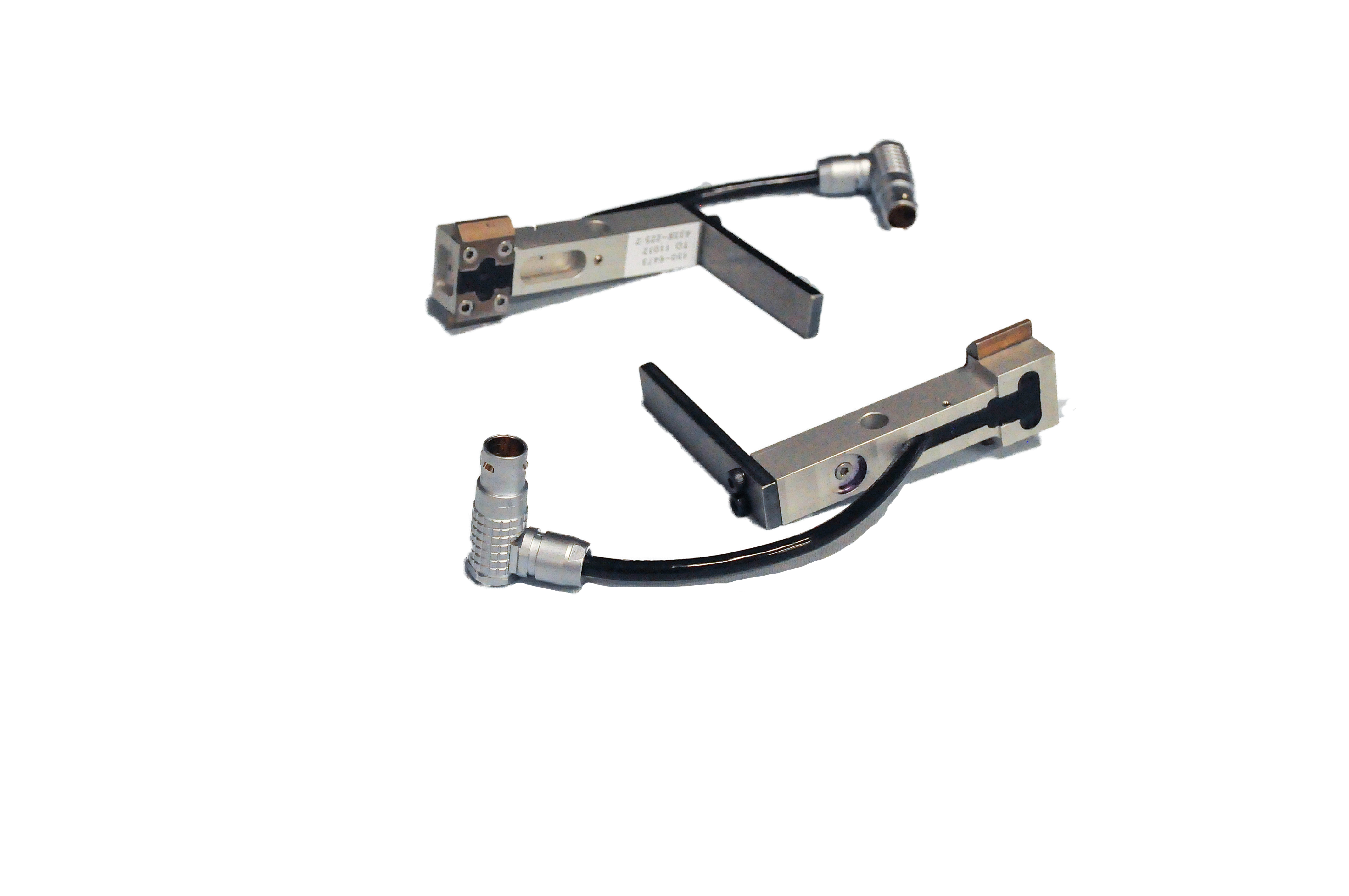

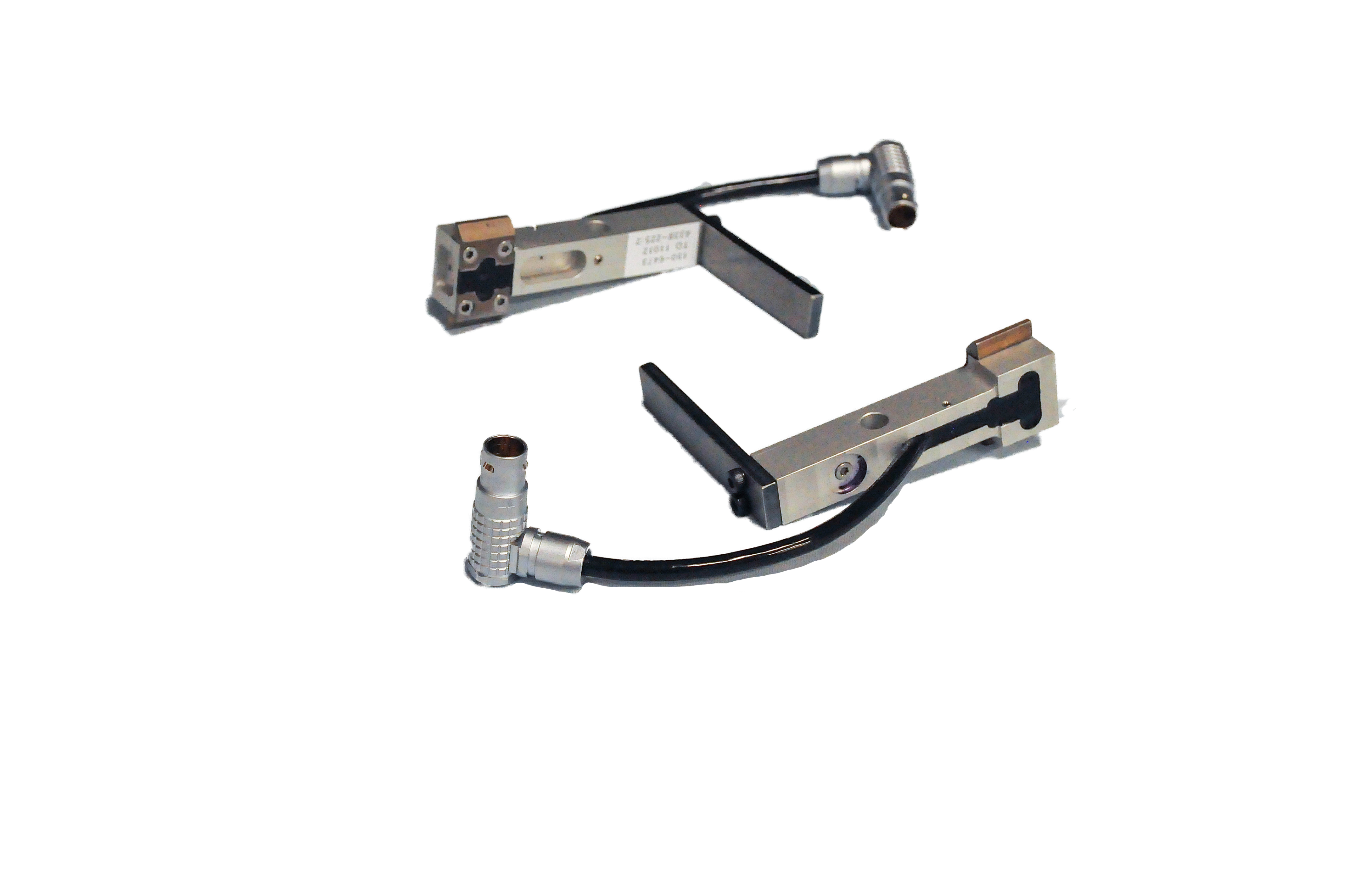

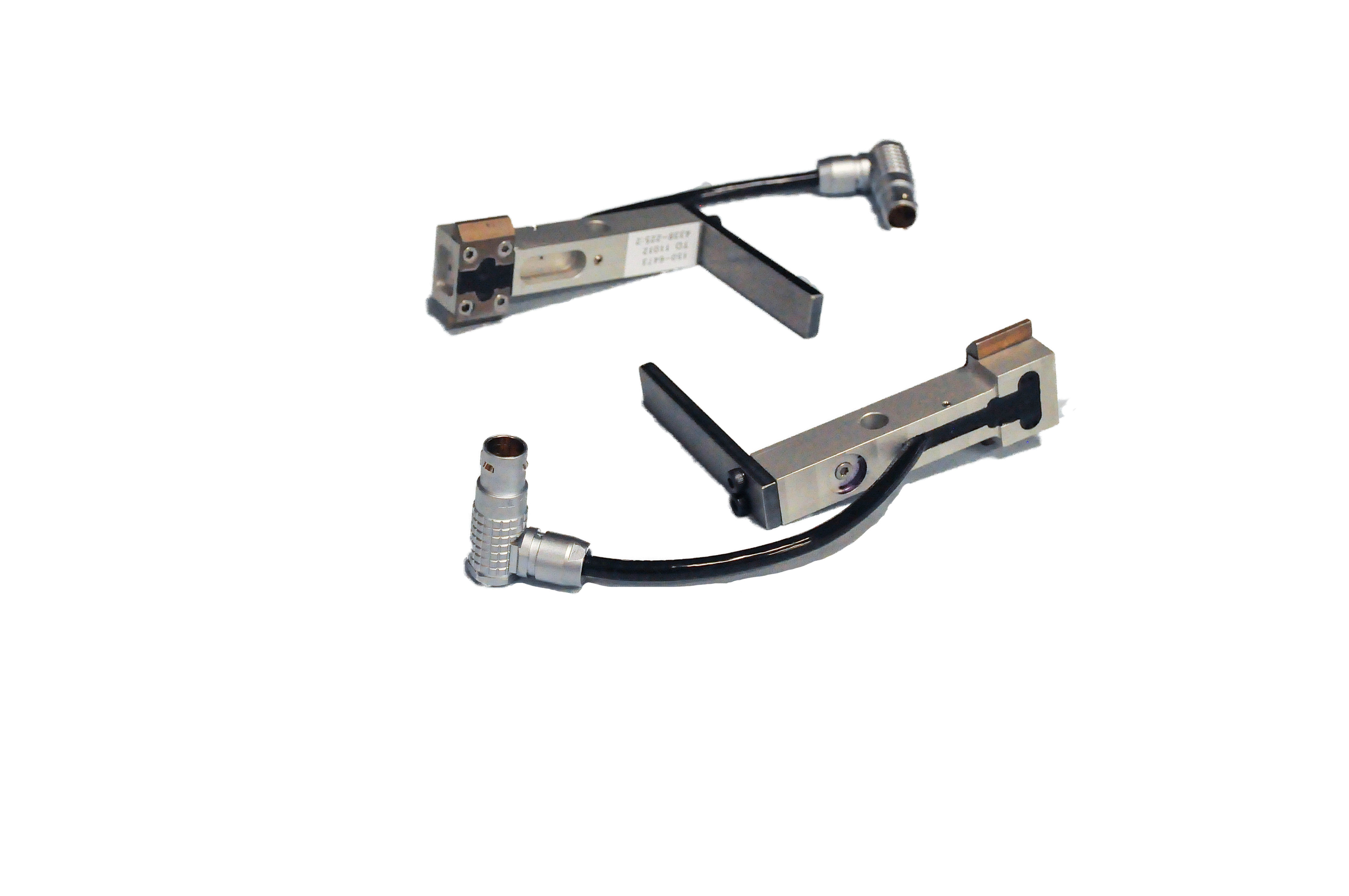

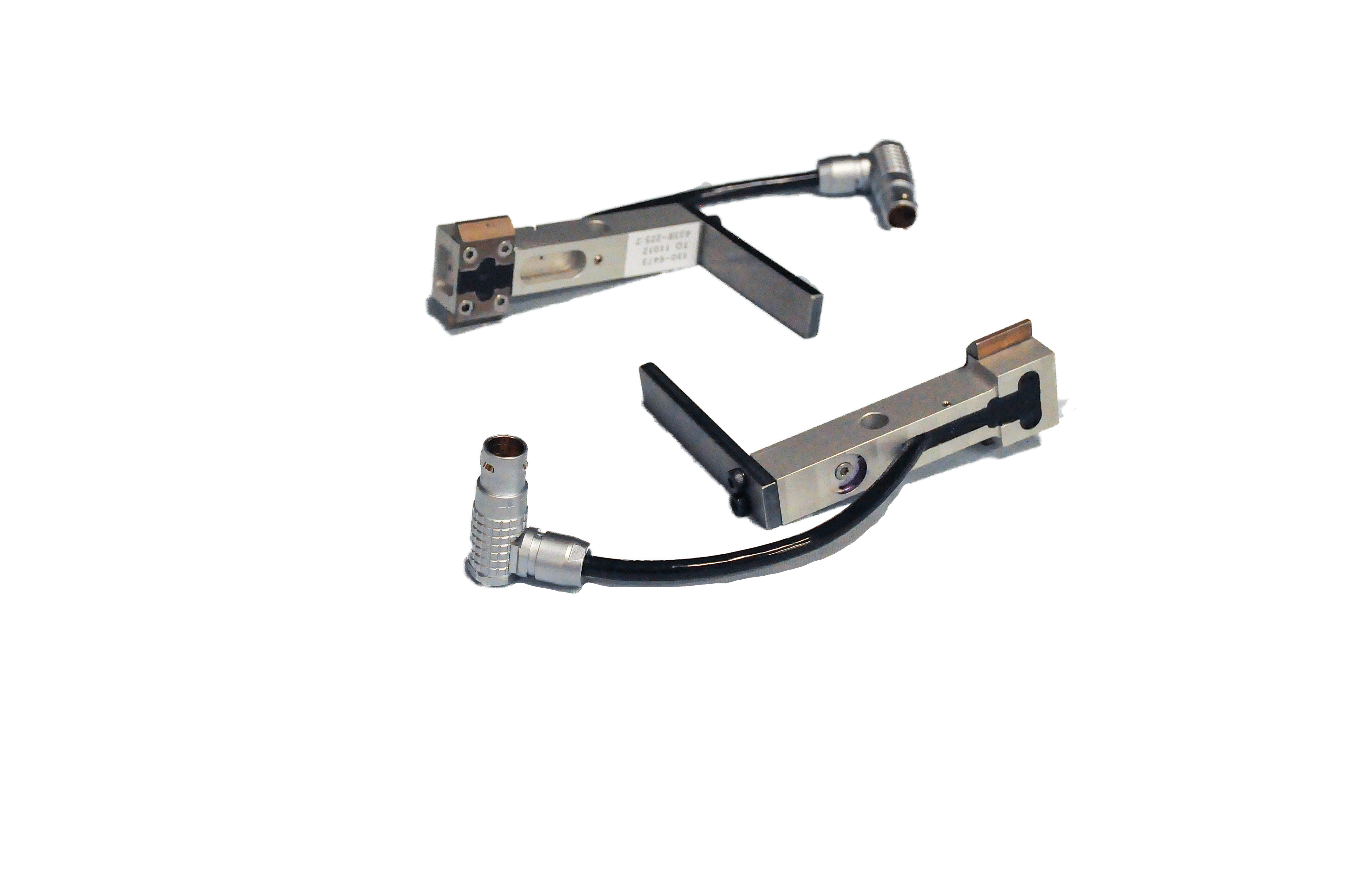

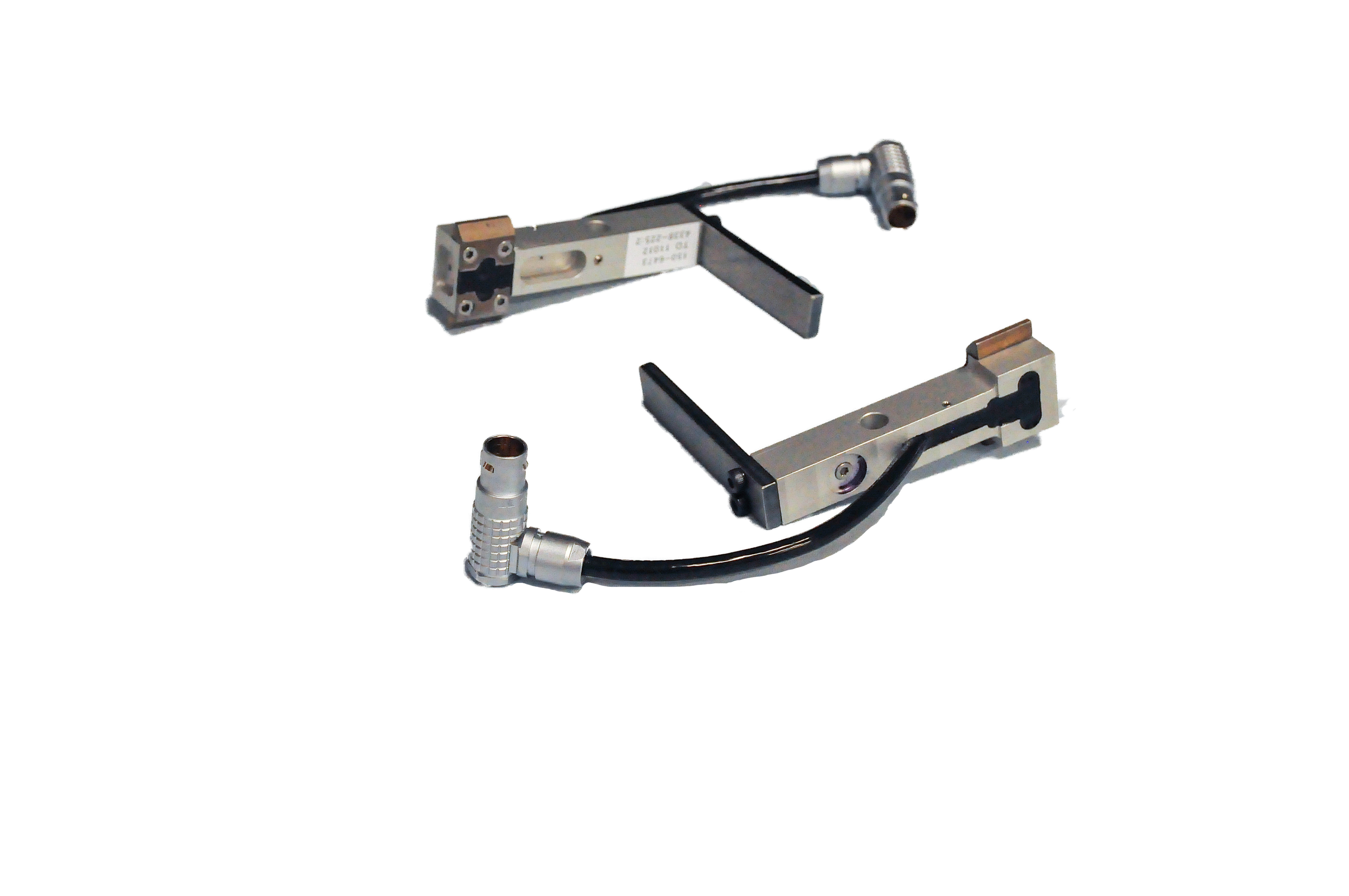

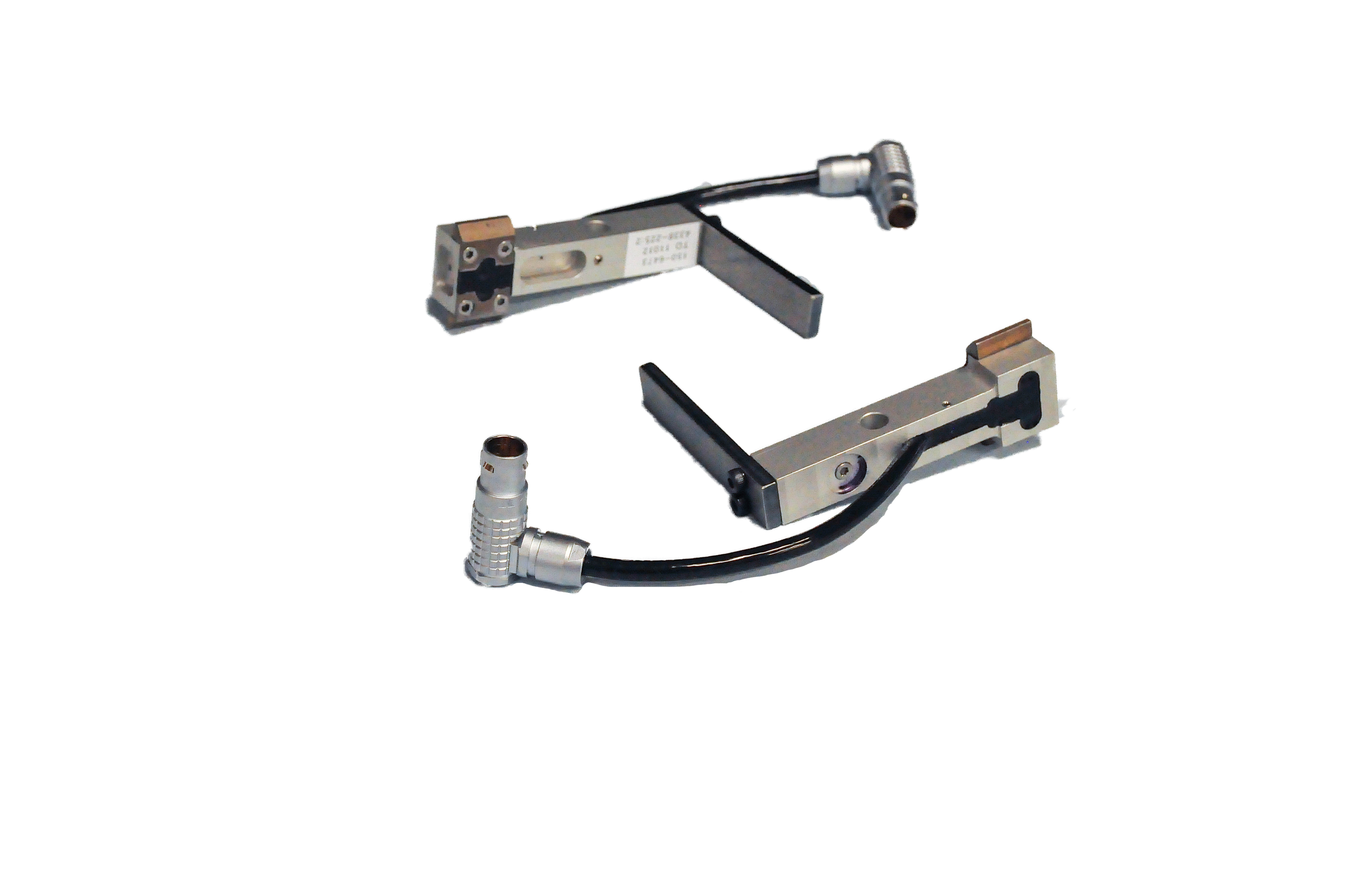

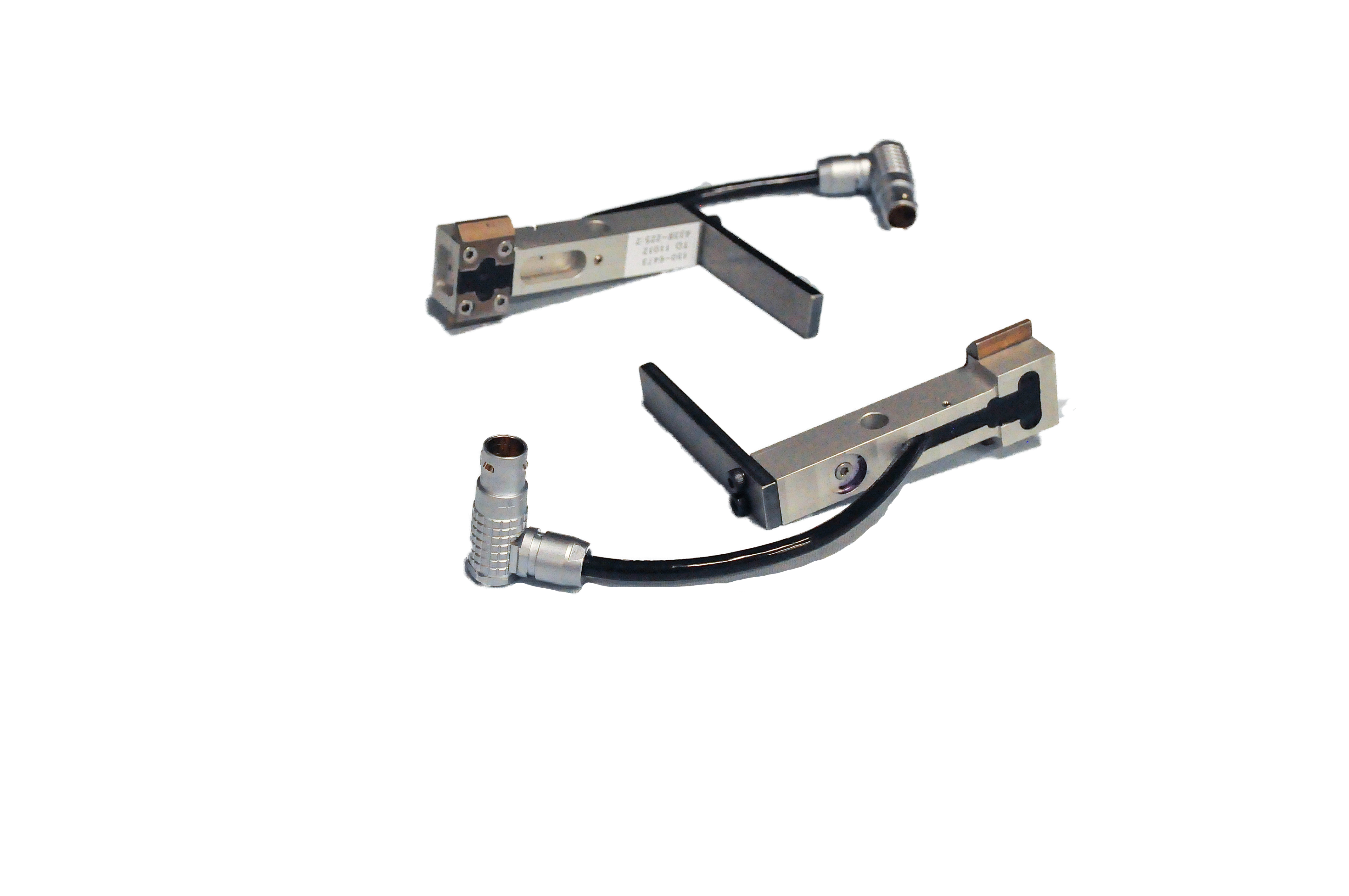

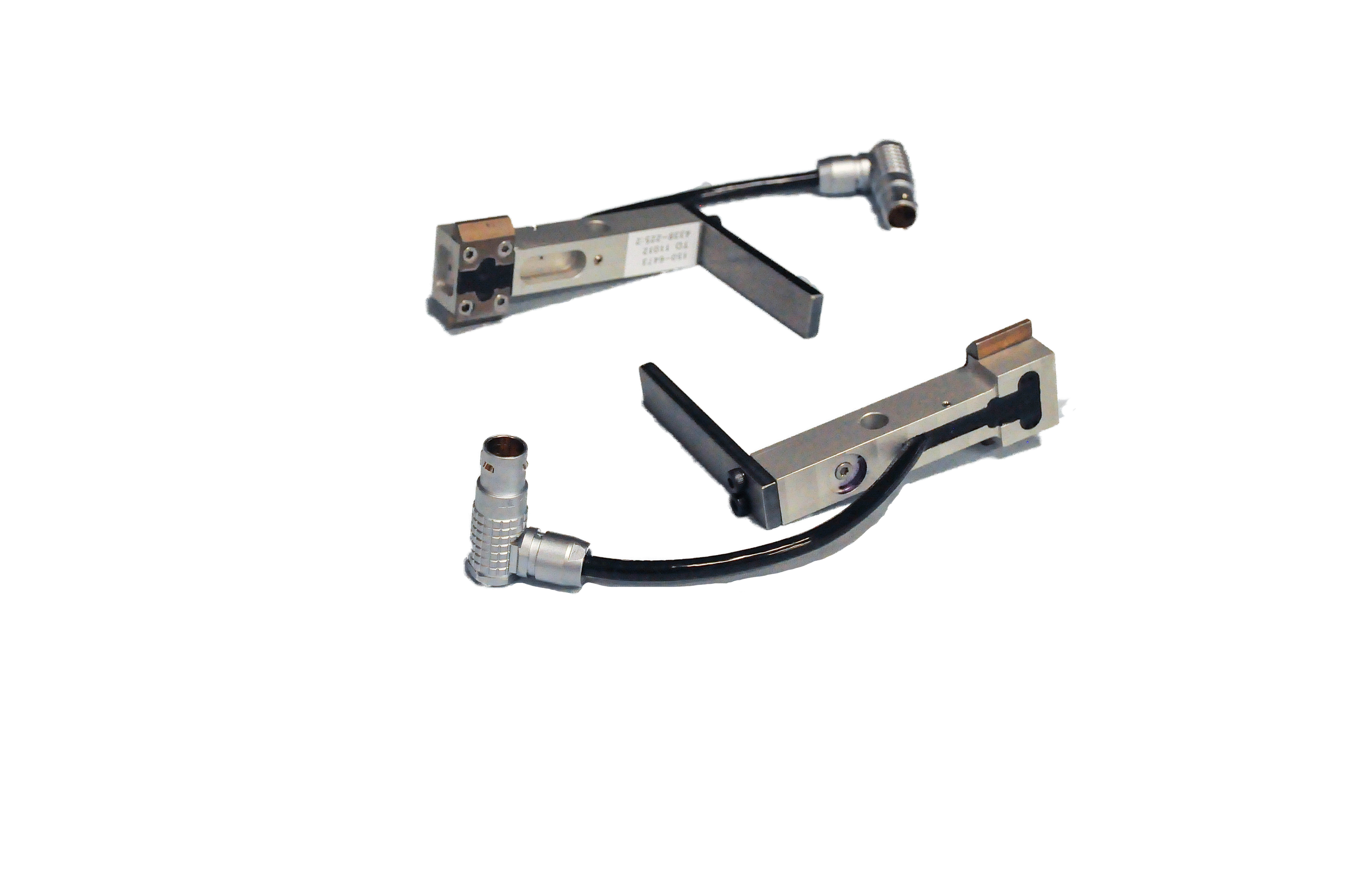

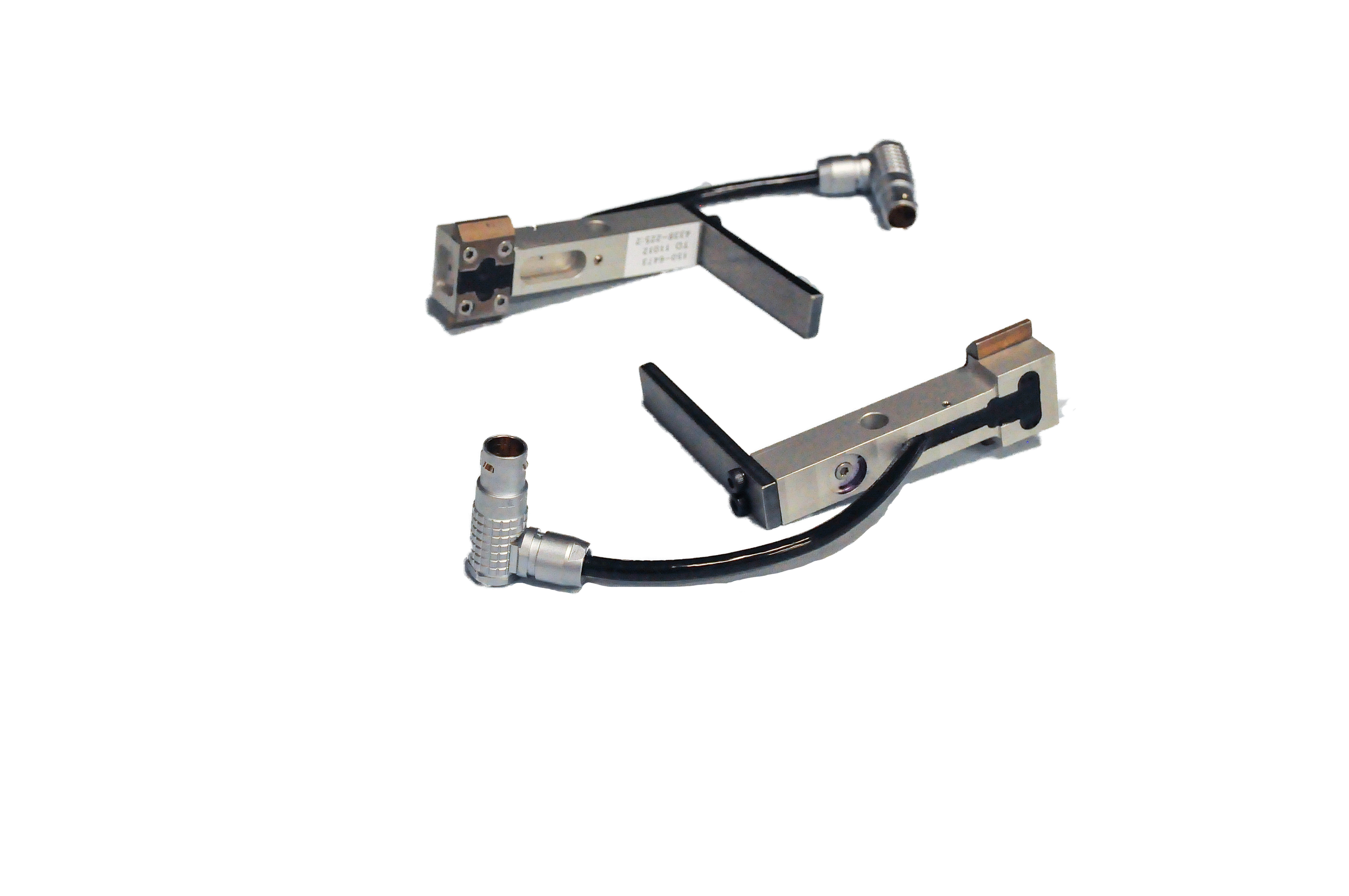

QUARTZ ENCODER CABLE

SKU: CBL-PA-ENCODER

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

QUARTZ IO CABLE

SKU: CBL-PA-IO

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

QUARTZ IO CABLE

SKU: CBL-PA-IO

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

REFURBISHED , CABLE ASSY, 3FT PIGTA

SKU: CBL1624

Engineered for durability and consistent signal/power transmission, these cables are compatible with a wide range of NDT equipment. They are built to withstand the stresses of industrial use while maintaining reliable performance in various testing environments.

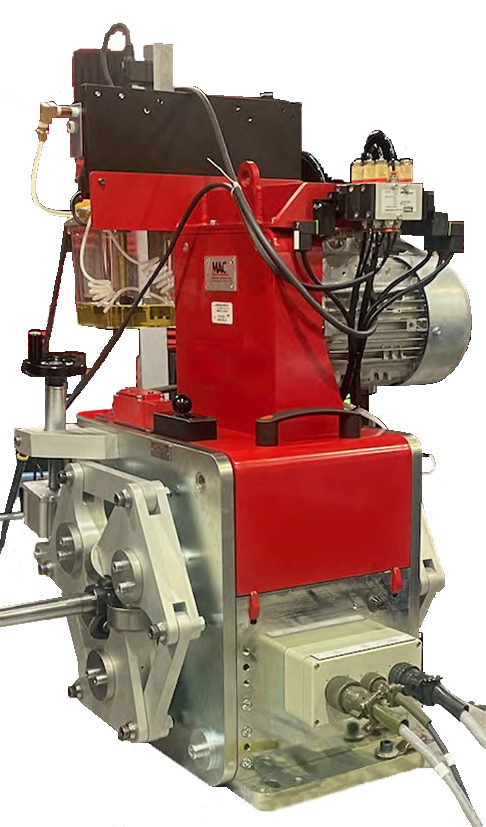

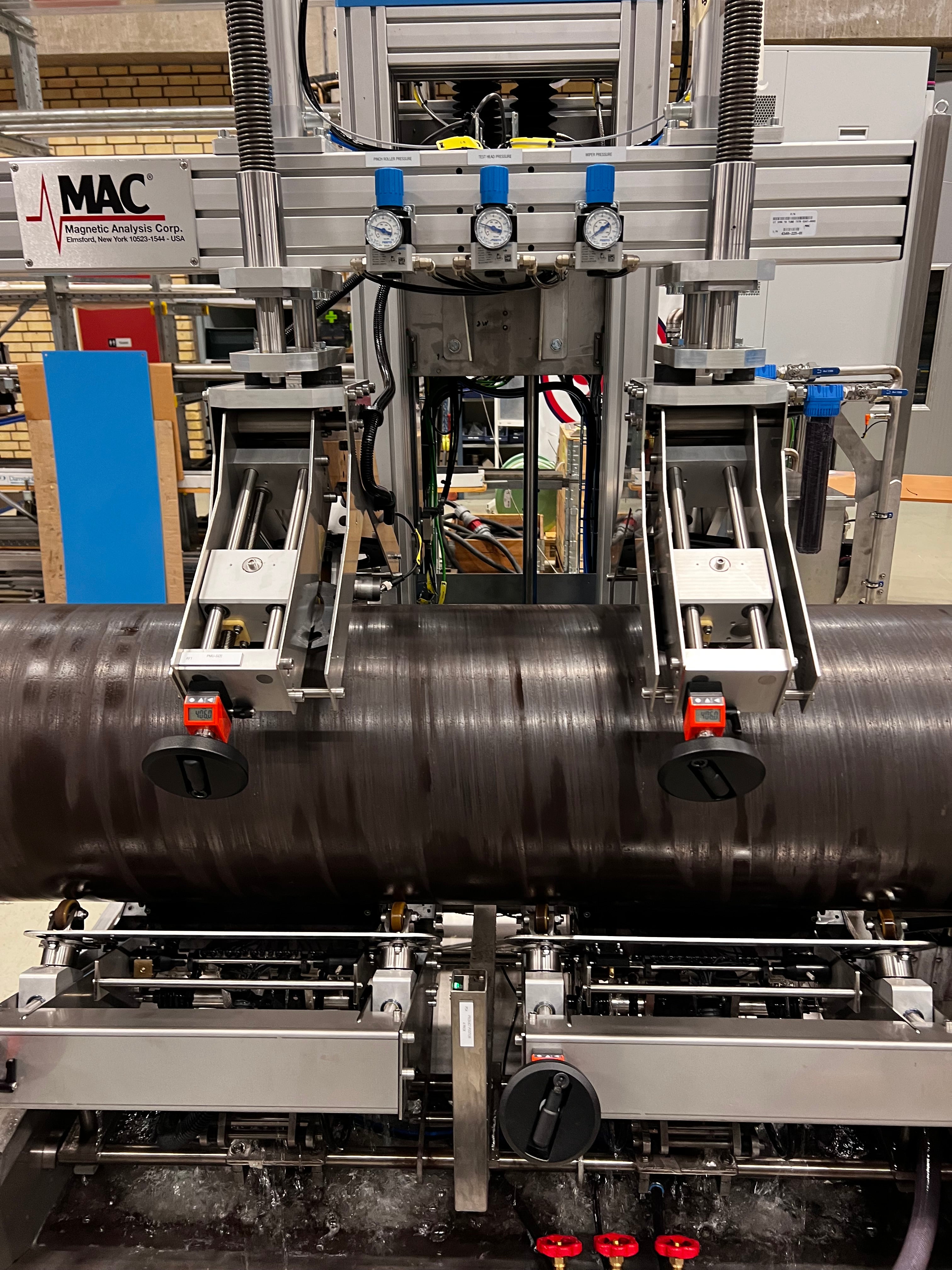

ROTOMAC® EDDY CURRENT ROTARIES

Eddy Current Rotary Mechanism to Detect Seam Type Defects in Tube and Bar

MAC Rotaries use the unique qualities of eddy current rotary probe technology to detect long continuous surface flaws which may not be detected by encircling test coils.

Operate with MultiMac® eddy current electronics.

Systems with two, four, or six probes, each with its own detector channel.

Accurate Distance Compensation ensures a uniform defect signal, even with off center or out of round material.

Choose test headplates for surface or air ride configurations, depending on surface conditions, sizes, and test specifications.

Dynamic breaking for quick stop of test probe headplate rotation.

Rotary probes, unlike encircling test coils, are not affected by throughput speed changes such as occur in parts forming, because the probes spin continually around the test material at a fixed speed.

Operates automatically as defects in the bar or wire create flaw signals, activate alarms, paint markers and other devices.

Test magnetic and nonmagnetic material from 1/8″ (3mm) to 7.1″ (180mm) diameter.

Method of Choice for Seam Type DefectsMultiMac® eddy current electronics provide the controls, processing and analysis for the Rotary. MultiMac® can also assign channels to an encircling coil test to detect short, intermittent defects, in combination with the rotary test, where needed.

ROTOMAC® 25RM SLOW THROUGHPUT SPEED ROTARY

Cost-Effective Eddy Current Rotary for Testing Wire & Rod

The Rotomac®25 RM is the latest in MAC’s line of eddy current rotaries. Packaged with our Minimac® II eddy current electronics, it provides cost effective, reliable on-line inspection for longitudinal surface defects in wire, rod and heavy wall tube, 3 to 25mm diameter.

It is designed for use in cold header operations, spring making, strut rod production and similar slow throughput operations.

Operates at 1000 RPM.

Throughput speeds up to 12 meters per minute.

Out-of-round product can be inspected using our highly accurate distance compensation with absolute test probes.

Bushings keep product centered during test.

New air ride probe arm design, with convenient, easy access probe adjustment.

Standard singe phase AC power input.

ROTOMAC® 20mm HIGH SPEED ROTARY

High-Speed Testing of Small Diameter Wire, Rod & Tube for Longitudinal Defects

High-speed rotary features include:

Operation at speeds up to 18,000 RPM for high production output.

Highly sensitive non-contact testing with superior results.

New and improved, easy to set up Distance Compensation (a critical factor in testing ovate wire).

Simple adjustment tools, with convenient dial-in diameter guide.

Two spinning test probes that can be adjusted simultaneously for dimensional changes.

Quick twist-on bushing holders.

Probes that can be easily centered on the test product’s center of rotation.

Simple probe replacement.

Meets all applicable safety requirements.

The 20mm Rotomac® HS Rotary delivers high-speed ECT (Eddy Current Testing) for continuous wire operations that include drawing, spring-making, parts forming, and shape and cut. The system is designed to detect longitudinal surface flaws such as seams and laps, in products measuring from 2 to 20mm (0.0787-0.7874”) in diameter

Applications Include:

Continuous wire operations such as drawing, spring-making, and parts forming lines.

Straight and cut operations.

Operates in-line with straighteners, or off-line in a separate test station.

Ferromagnetic, non-ferromagnetic, and austenitic materials.

Tests round and ovate material.

EDDY CURRENT TECHNOLOGY IN NDT

MAC’s® Eddy Current Testing (ECT) systems incorporate computer-based test instruments and test coils that use two ECT coil technologies: encircling and sector coils, and spinning or rotary probe coils.

Encircling and sector Eddy Current coil tests perform in this manner:

The product is passed through or adjacent to an electrical test coil, which has been excited by an alternating current.

This induces a flow of eddy currents around the test material or in the case of a sector coil, in the area under the coil.

Short, intermittent anomalies or flaws cause a variation in the eddy current pattern, which the instrument detects.

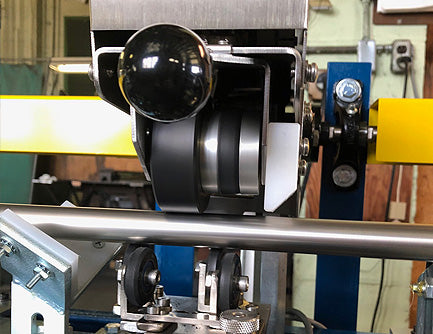

ROTOMAC® HS 20MM

High-Speed Testing of Small Diameter Wire, Rod & Tube for Longitudinal Defects

High-speed rotary features include:

Operation at speeds up to 18,000 RPM for high production output.

Highly sensitive non-contact testing with superior results

New and improved, easy to set up Distance Compensation (a critical factor in testing ovate wire).

Simple adjustment tools, with convenient dial-in diameter guide.

Two spinning test probes that can be adjusted simultaneously for dimensional changes.

Quick twist-on bushing holders.

Probes that can be easily centered on the test product’s center of rotation.

Simple probe replacement.

Meets all applicable safety requirements.

The 20mm Rotomac® HS Rotary delivers high-speed ECT (Eddy Current Testing) for continuous wire operations that include drawing, spring-making, parts forming, and shape and cut. The system is designed to detect longitudinal surface flaws such as seams and laps, in products measuring from 2 to 20mm (0.0787-0.7874”) in diameter

Applications Include:

Continuous wire operations such as drawing, spring-making, and parts forming lines.

Straight and cut operations.

Operates in-line with straighteners, or off-line in a separate test station.

Ferromagnetic, non-ferromagnetic, and austenitic materials.

Tests round and ovate material.

ROTOMAC® Rotaries

ROTOMAC® EDDY CURRENT ROTARIES

Eddy Current Rotary Mechanism to Detect Seam Type Defects in Tube and Bar

MAC Rotaries use the unique qualities of eddy current rotary probe technology to detect long continuous surface flaws which may not be detected by encircling test coils.

Operate with MultiMac® eddy current electronics.

Systems with two, four, or six probes, each with its own detector channel.

Accurate Distance Compensation ensures a uniform defect signal, even with off center or out of round material.

Choose test headplates for surface or air ride configurations, depending on surface conditions, sizes, and test specifications.

Dynamic breaking for quick stop of test probe headplate rotation.

Rotary probes, unlike encircling test coils, are not affected by throughput speed changes such as occur in parts forming, because the probes spin continually around the test material at a fixed speed.

Operates automatically as defects in the bar or wire create flaw signals, activate alarms, paint markers and other devices.

Test magnetic and nonmagnetic material from 1/8″ (3mm) to 7.1″ (180mm) diameter.

Method of Choice for Seam Type Defects

MultiMac® eddy current electronics provide the controls, processing and analysis for the Rotary. MultiMac® can also assign channels to an encircling coil test to detect short, intermittent defects, in combination with the rotary test, where needed.

ROTOMAC® 25RM SLOW THROUGHPUT SPEED ROTARY

Cost-Effective Eddy Current Rotary for Testing Wire & Rod

The Rotomac®25 RM is the latest in MAC’s line of eddy current rotaries. Packaged with our Minimac® II eddy current electronics, it provides cost effective, reliable on-line inspection for longitudinal surface defects in wire, rod and heavy wall tube, 3 to 25mm diameter.

It is designed for use in cold header operations, spring making, strut rod production and similar slow throughput operations.

Operates at 1000 RPM.

Throughput speeds up to 12 meters per minute.

Out-of-round product can be inspected using our highly accurate distance compensation with absolute test probes.

Bushings keep product centered during test.

New air ride probe arm design, with convenient, easy access probe adjustment.

Standard singe phase AC power input.

ROTOMAC® 20mm HIGH SPEED ROTARY

High-Speed Testing of Small Diameter Wire, Rod & Tube for Longitudinal Defects

High-speed rotary features include:

Operation at speeds up to 18,000 RPM for high production output.

Highly sensitive non-contact testing with superior results.

New and improved, easy to set up Distance Compensation (a critical factor in testing ovate wire).

Simple adjustment tools, with convenient dial-in diameter guide.

Two spinning test probes that can be adjusted simultaneously for dimensional changes.

Quick twist-on bushing holders.

Probes that can be easily centered on the test product’s center of rotation.

Simple probe replacement.

Meets all applicable safety requirements.

The 20mm Rotomac® HS Rotary delivers high-speed ECT (Eddy Current Testing) for continuous wire operations that include drawing, spring-making, parts forming, and shape and cut. The system is designed to detect longitudinal surface flaws such as seams and laps, in products measuring from 2 to 20mm (0.0787-0.7874”) in diameter

Applications Include:

Continuous wire operations such as drawing, spring-making, and parts forming lines.

Straight and cut operations.

Operates in-line with straighteners, or off-line in a separate test station.

Ferromagnetic, non-ferromagnetic, and austenitic materials.

Tests round and ovate material.

SPIN THE TUBE TEST

Spin-The-Tube systems for testing product used for transporting gases and fluids in oil, gas and mining operations.

TacTic® ACCESSORIES

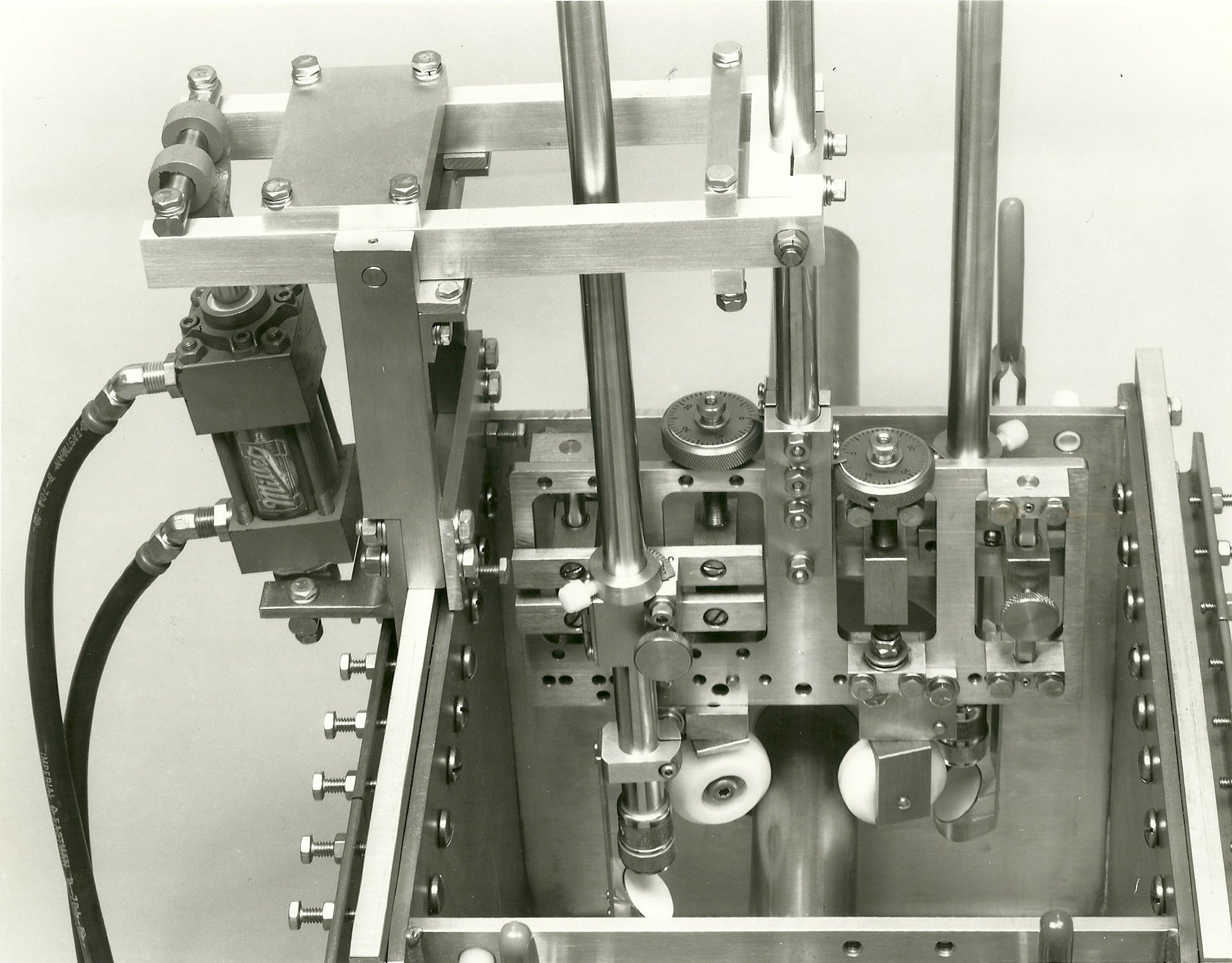

Model 411 Series Dual Probe Followers

These followers mount on any standard TacTic® tester tank. These air-loaded followers ride the material on angulated wheels or balls to ensure excellent following action on crooked materials. TacTic recommends the use of followers on all materials above 1/2″ in diameter.

Rugged, lockable calibrated controls enable precise control of the orientation of each transducer. These units can perform normal beam, circumferential or axial scanning. See Bulletin 4110.

Model 444 (4-probe) and Model 446 (6-probe) Followers

The Model 444 (4-probe) and Model 446 (6-probe) Followers are used for the inspection of billets and large pipes and tubes up to 20 inches in conventional immersion tanks.

These Followers use a combination of an air cylinder and an electric motor to lift and lower the scanner to facilitate adjustments and to permit rapid transit along the length of the tank.

Model 45 Series Positioners

The 45-9 is the most popular system of our extensive line of positioners. It has precise 3-axis control with offset adjustments calibrated to 0.001″ (0.05 mm in the metric model) and rotational to 0.25°. The rotation range about the search tube axis is ± 90°. See Bulletin 453.

Model 140 Series Miniature Manipulators

These small manipulators mount on the end of a standard 3/4″ search tube and its bottom connector receives a standard UHF threaded transducer case. Each manipulator provides a ± 54° angulation in one plane only. When the search tube is supported in a positioner such as a Model 45-9, or a Follower such as a Model 444, this angulation is sufficient for the detection of defects of almost any orientation. If you need another rotation axis, these units may be connected in Series with 90° rotation between them. See Bulletin 1400.

TacTic® Material Handling Air-actuated “Extended” Drive Units Model Model 204 and 205 Series

Model 204 and 205 Series Air-actuated “Extended” Drive Units are overhead drive wheels.