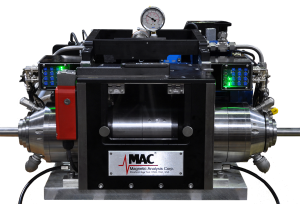

Demagnetizers permit efficient, continuous elimination of unwanted magnetism in ferrous rod, wire, bar and tubing

Ultrasonic Testing of Tube Weld Quality During Production

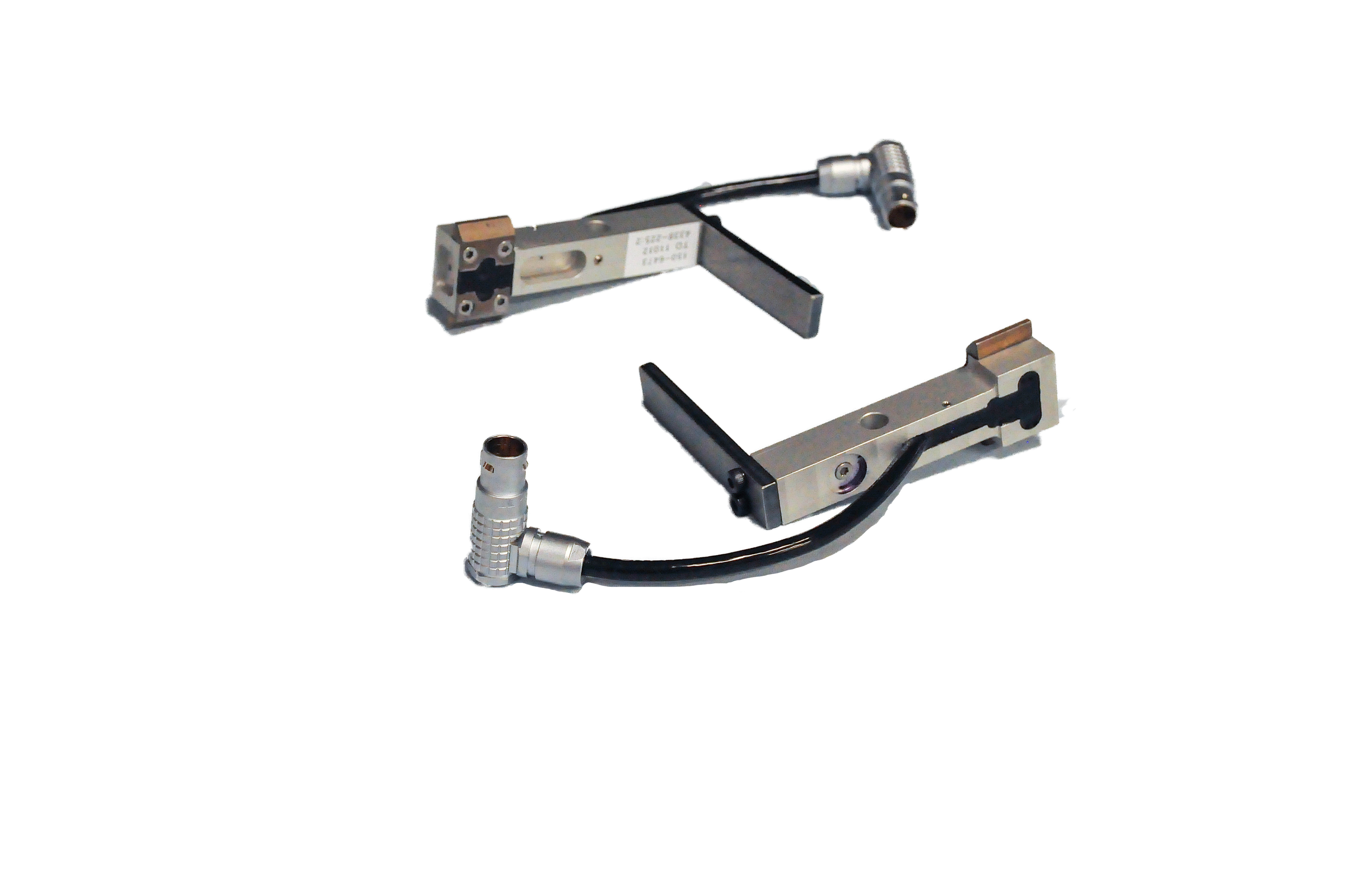

For Inspecting High Precision Small Diameter Tube & Bar

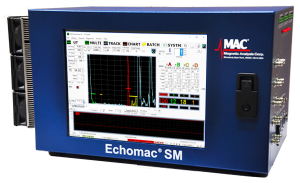

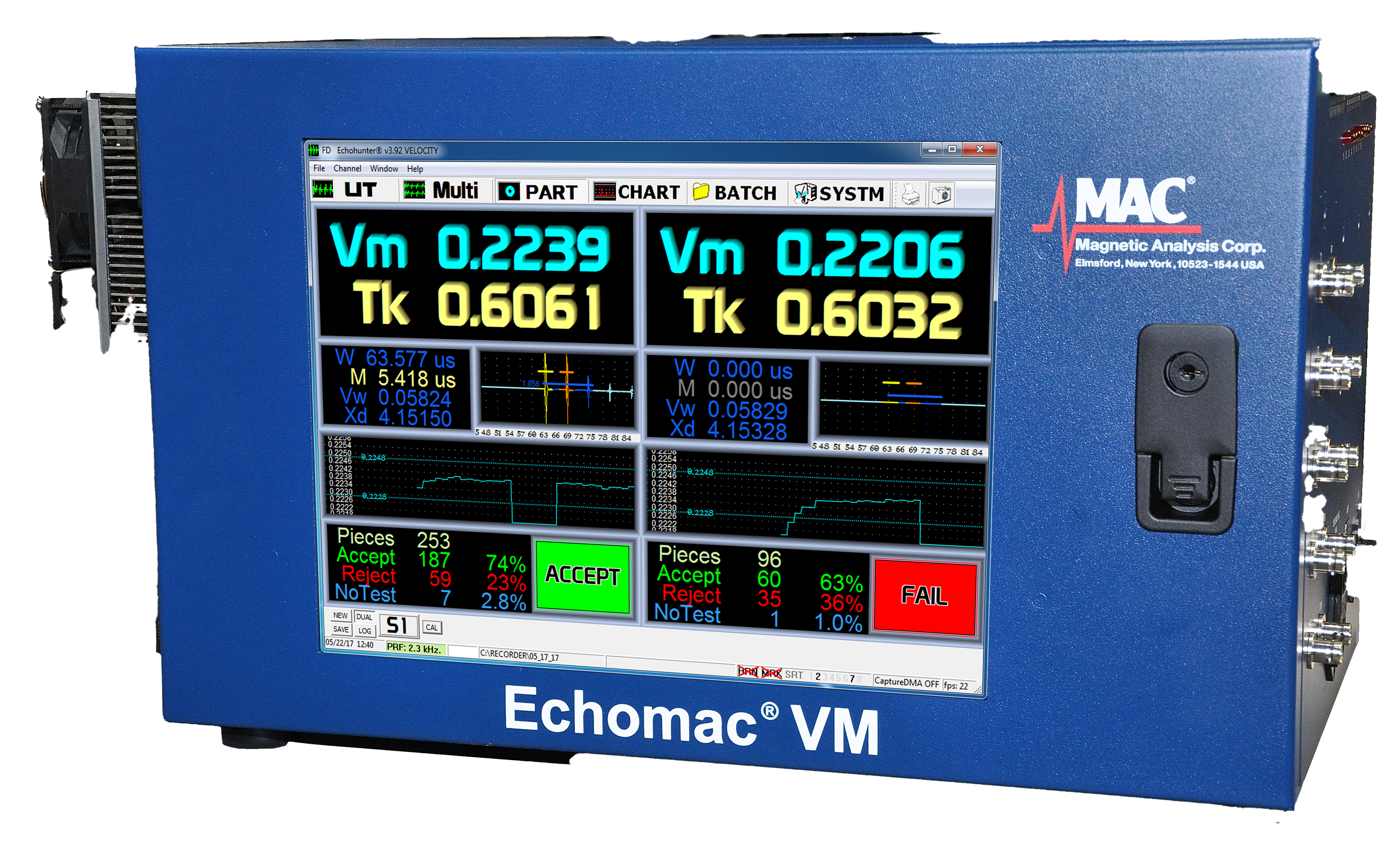

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

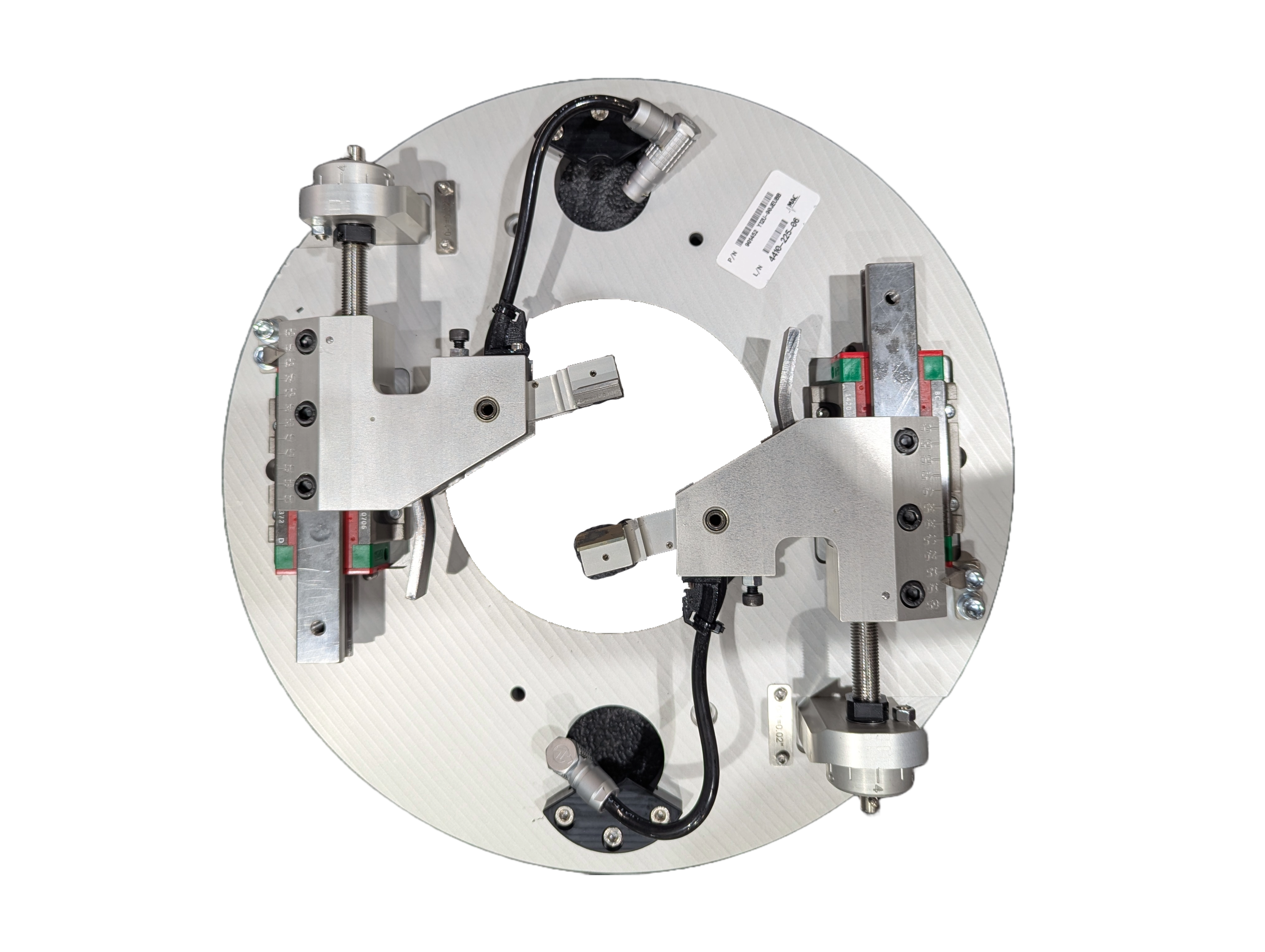

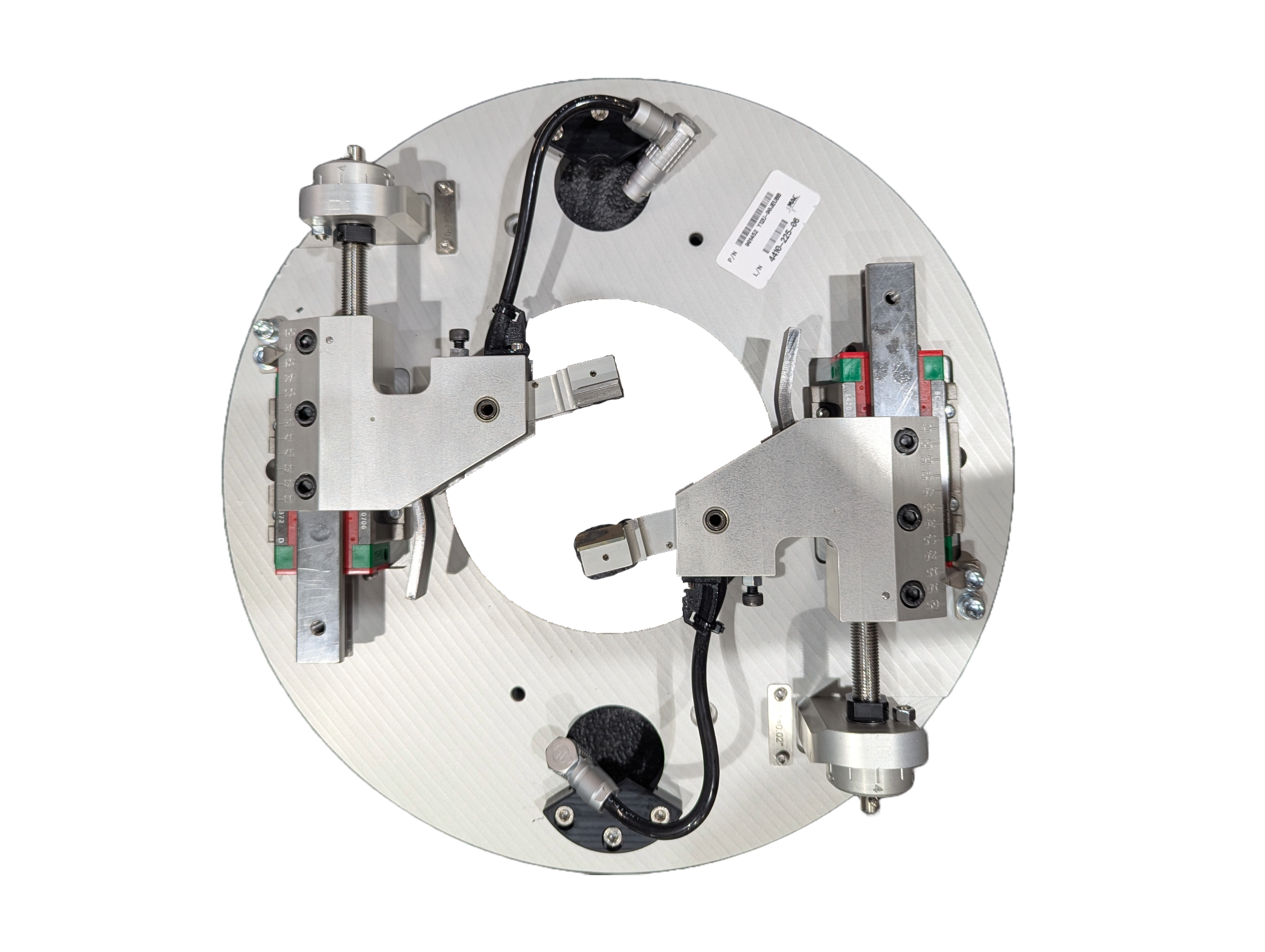

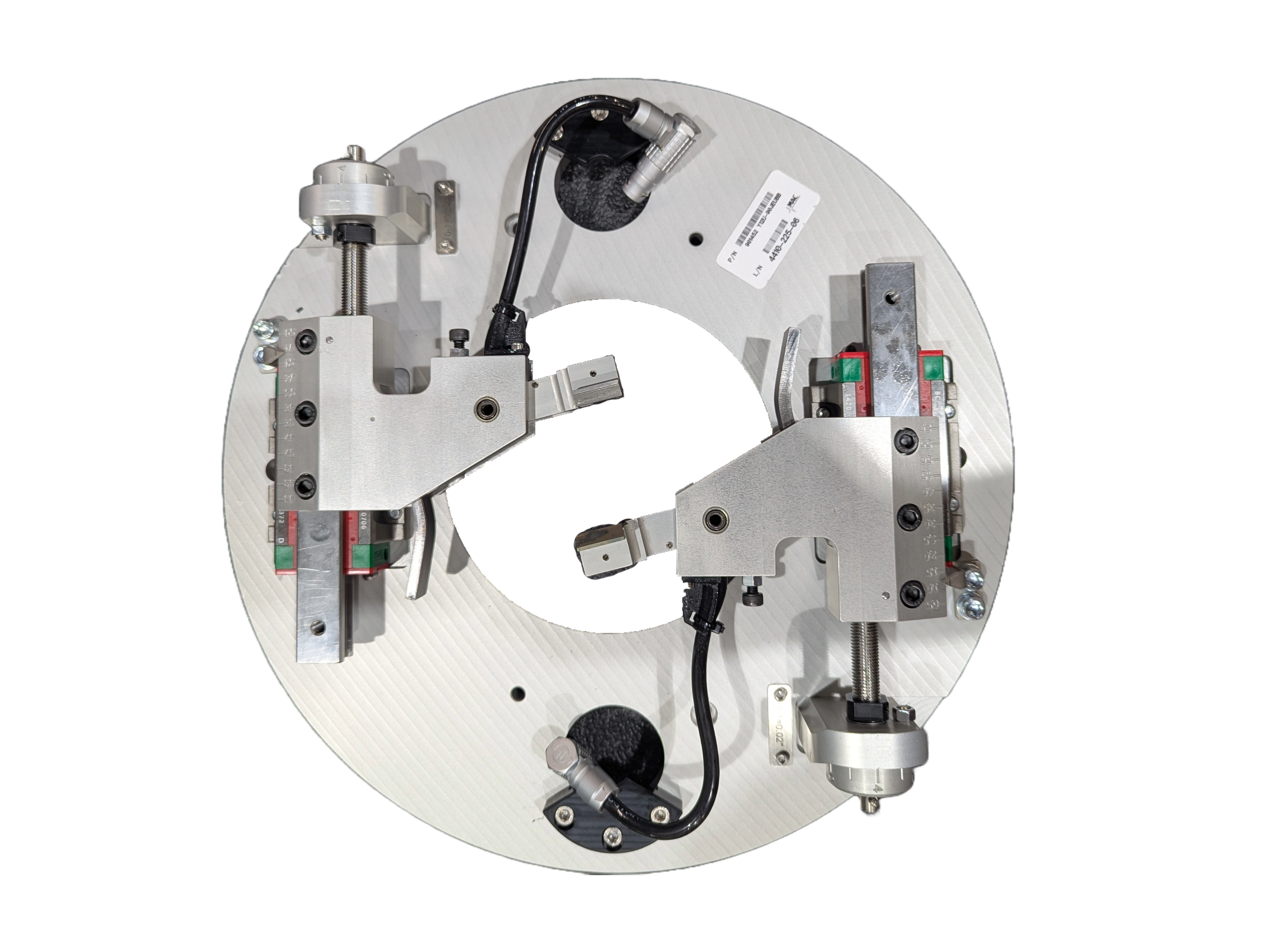

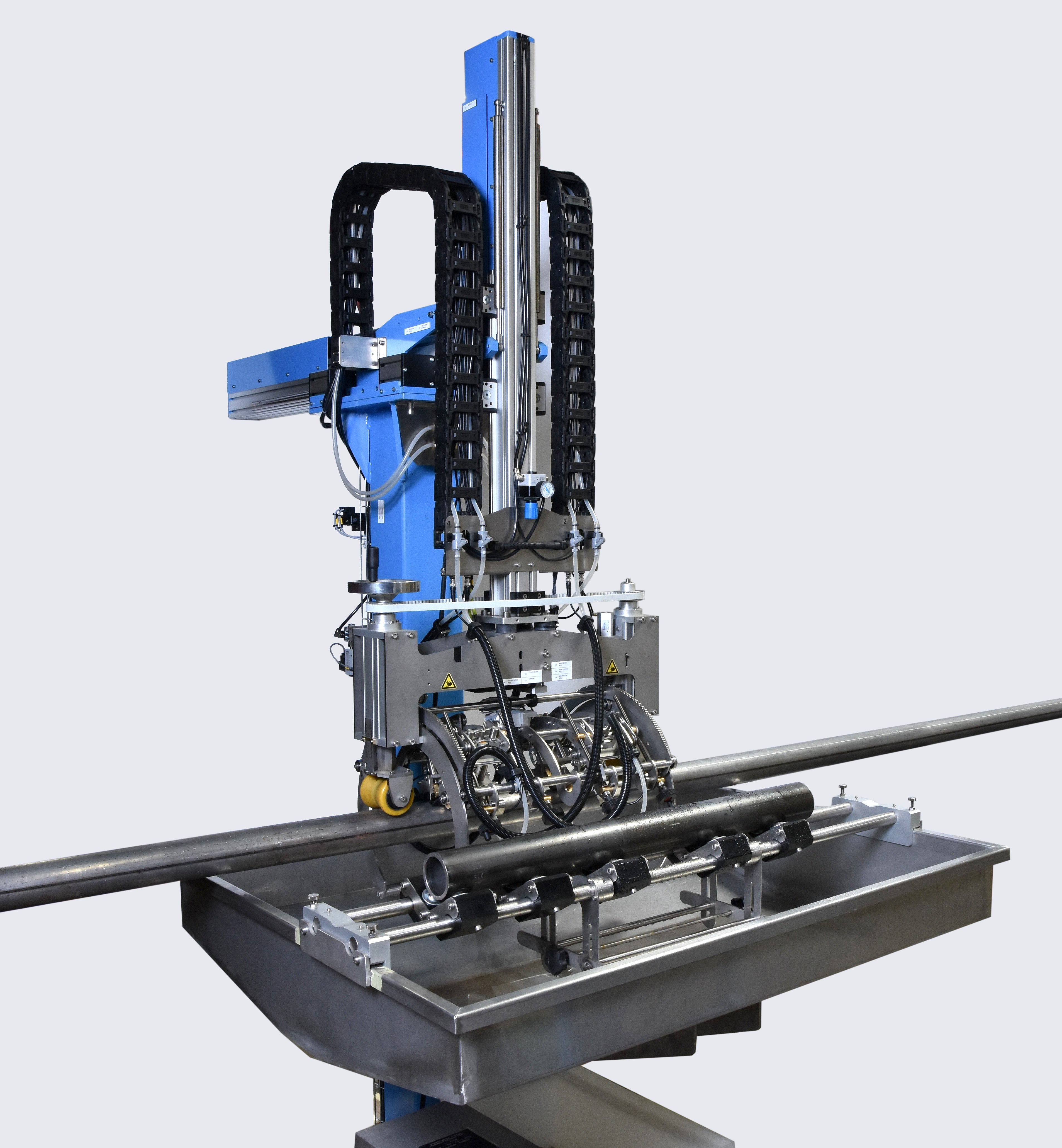

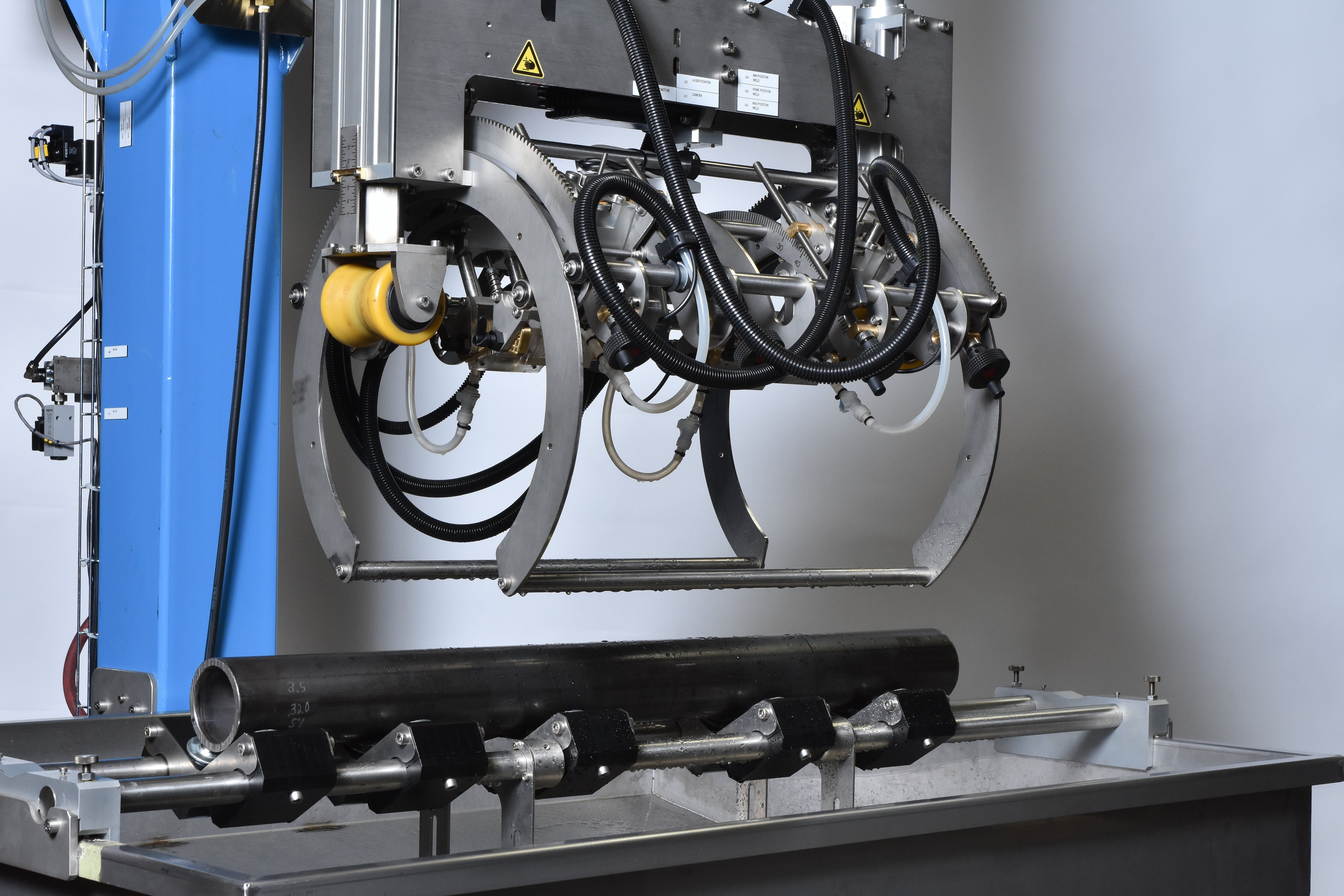

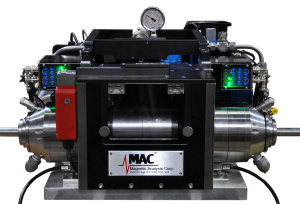

Ultrasonic Spin-the-Tube Inspection System with APC Pitch Control Technology

Ultrasonic Instrument for Flaw Detection, Thickness, and Dimensional Measurement in Tube & Bar

For Use in Production Environments

For Full Body Inspection of Bar for Defects

The system is scalable, allowing the flexibility of adding channels as needed to handle a large range of part geometries.

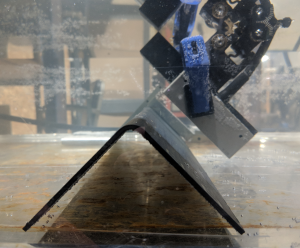

For Detecting Weld Zone Defects in Tube & Pipe

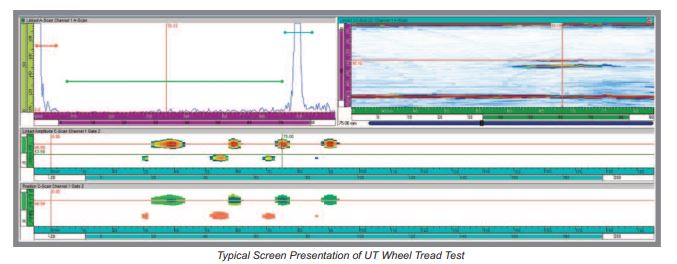

Robust, Cost Effective UT Phased Array System for In-Service Rail Wheel Tread Inspection

Simple, Effective Ultrasonic Instrument With up to 6 Channels

Velocity Measurement to Assess Nodularity in Ductile Iron Cast Automotive Components