The Origins of Practical EM Testing & the Historical Contributions of MAC to NDT

Magnetic Analysis Corporation, most commonly referred to as MAC, is a major worldwide source of NDT equipment including eddy current, flux leakage, and ultrasonic inspection systems. Since its beginnings to present day, MAC has been the first to market with various types of groundbreaking NDT equipment.

A Look at NDT Testing

Non-destructive testing or NDT has become the go-to quality assurance management tool for the examination of materials and components. Perhaps the best feature about this form of testing is that it allows materials to be examined without changing or destroying their usefulness.

NDT of Duplex Stainless Steel

This paper will discuss the selection of inspection methods for testing Super Duplex stainless product for the offshore energy exploration, petrochemical, food & beverage, and power generation industry. We will show how Eddy Current and Ultrasonics will meet requirements set up by ASTM, and EN standards in regards to Super Duplex stainless steel.

Modern Comparators

Rapid inspection of fasteners and metal parts for properties such as heat treatment, hardness, and alloy is a key requirement in meeting today’s stringent specifications in the automotive, aerospace, nuclear, and similar demanding industries. Improperly heat-treated parts can result in costly machining issues, rework, lost production time, and product failure.

Testing Wire & Rod

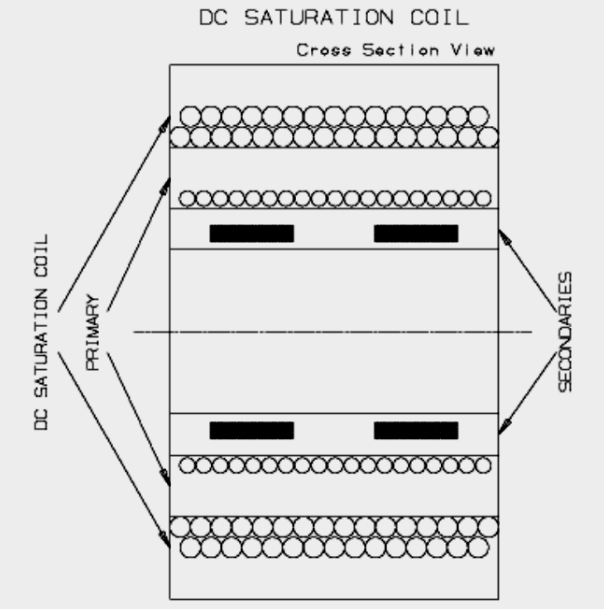

Eddy current technology is the go-to wire and cable testing method for checking continuity, alloy, and other conditions as well as for locating welds and splices.

Advances in Large Diameter Pipe Inspection

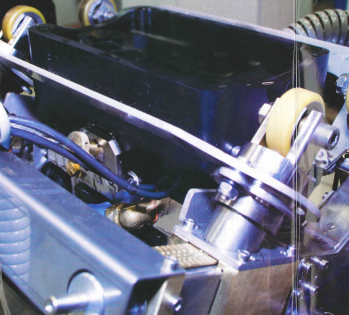

A new design has been developed for the ultrasonic testing (UT) of drawn over mandrel seamless carbon steel tube and pipe that enables manufacturers to test with fewer adjustments to accommodate varying diameters of material, without the need for time-consuming configuration changes.

MAC A Major Player in the NDT Industry

Since being founded in 1928 in Long Island City, New York, Magnetic Analysis Corporation (MAC) has 85 years of experience in the nondestructive testing (NDT) industry. As one of the first companies in the world to develop a fully computerized rotary eddy current tester, MAC is truly a world-class NDT pioneer.

Detecting Metallic Inclusions And Defects In Copper Tube

The Victaulic copper connection system complies with EN1057 half hard copper tubing sizes DN50 to DN150 (2 to 6") and can withstand pressures up to 2,450kPa/355psi depending on the type and size of copper tubing. The product line consists of WRAS-approved Style 606 rigid coupling with grade ‘EW’ EPDM gasket for joining copper tubing and a range of full-flow, standard radius wrought copper fittings supplied with grooves.

Planning Ahead for a Successful NDT System

As a start, suppliers should recognize that it is fast becoming mandatory for any long stock producer to pass 100 percent of the product through a test station to assure that customer expected quality levels are met.

Meeting Standards For Testing Large OCTG Tube and Pipe

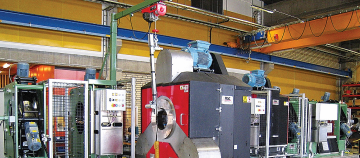

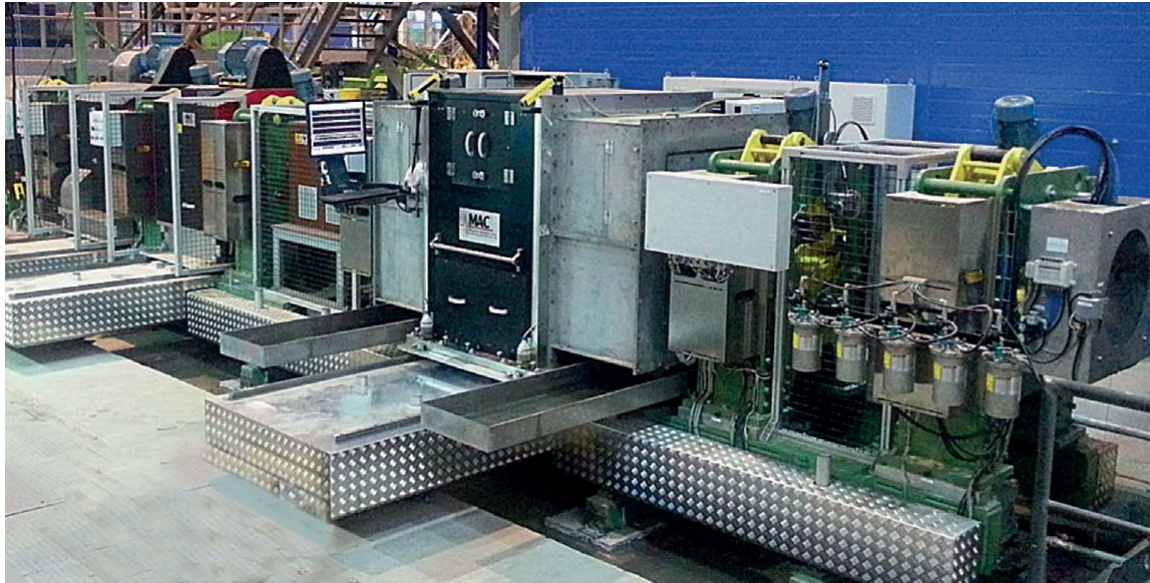

Magnetic Analysis Corp. (MAC) has recently supplied a test system to a Russian mill to inspect tube and pipe, up to 500mm (19.6”) diameter. The system features MAC’S largest ever Echomac® Ultrasonic Rotary tester combined with 500mm Rotoflux® Transverse and Longitudinal testers.

High Performance Testing

MAGNETIC Analysis Corporation (MAC) will feature the new Minimac 55 eddy current tester at this year’s Tube Southeast Asia show in Bangkok, Thailand, in September.

MAC Spotlight Article

Vielseitig, flexibel und nah am Kunden: Die US-amerikanische Magnetic Analysis Corporation (MAC) ist ein führender Anbieter zerstörungsfreier Prüfgeräte. Das Unternehmen, das 1928 gegründet wurde, hat seinen Sitz in Long Island City, New York. In den vergangenen 87 Jahren hat sich das Unternehmen zu einem weltweit tätigen Anbieter zerstörungsfreier Prüfgeräte entwickelt.