WIRE & CABLE TECHNOLOGY INT’L JANUARY 2021

Jean R. Gould, Marketing Manager, Magnetic Analysis Corp., Elmsford, NY, USA, says:

“Magnetic Analysis Corp. offers a range of eddy current test instruments and systems for detecting surface and sub-surface defects in copper and copper alloy wire and bar. This versatile and generally cost-effective technology is being used in a broad range of wire and rod applications.

“A USA wire alloy producer of wire for components and conductors has been successfully using MultiMac® single-channel eddy current testers for several years to inspect its full line of wire products, including zirconium copper and beryllium copper alloys, ranging from 0.033" to 0.25" (0.838 to 6.35 mm) diameter. The test is part of the finish inspection conducted at speeds up to 200 fpm. Typical defects being detected include surface defects in plating, sub-surface anomalies in bonding, and inclusions in multiple layers. A noise-canceling test coil, which minimizes noise from mechanical vibration in the wire, provides improved performance.

“In another application, MultiMac eddy current testers will be used to inspect continuous copper wire rod, used as feedstock in the production of wire copper strips. The rods range from 0.5 to 3.5 mm (0.01968" to 0.13778"), and the test is looking for external defects such as scratches, dents, and gaps at speeds up to 20 mps. A specially designed Wire Tracker test coil platform will be used to provide stability in feeding the bar.

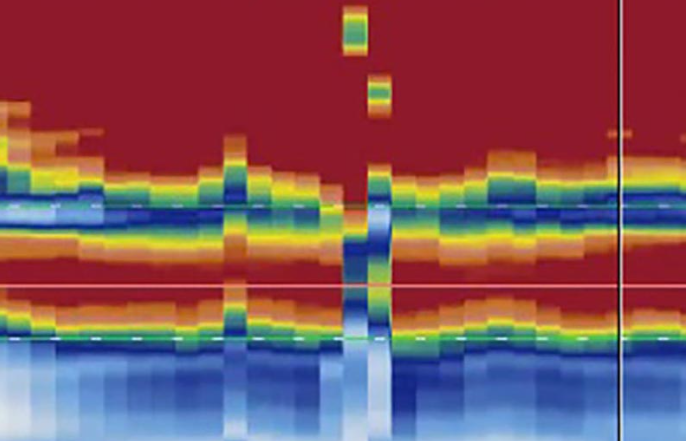

“At a continuous cast copper rod mill in China, a MultiMac eddy current tester is installed just before the coiler, but after the rod is produced and drawn down to smaller diameters. The tester assesses grade using MAC’s Grading Software and detects magnetic inclusions using a MID test coil. The Grading Software provides a convenient, efficient means of automatically categorizing the quality level of individual segments and entire coils of wire, rod, and bar during production.

"The user can customize the defect types, each based on a specific threshold gate, specify the maximum number of defects for each grade level, and configure reports. Surface defects and inclusions are detected and categorized. In this instance, rod graded higher is drawn down to even smaller diameters. Lower grades are not drawn down as much to avoid problems with breakage in the wire, which could end up causing disruptive downtime to rethread the drawing machine.”