STAINLESS STEEL WORLD AMERICAS APRIL 2015

100 percent is key

As a start, suppliers should recognize that it is fast becoming mandatory for any long stock producer to pass 100 percent of the product through a test station to assure that customer expected quality levels are met.

Surface quality testing

At the most basic level, any inspection line must at least test for surface quality (maximum defect depth), general straightness and uniformity of surface quality. Bar and tube surface testing capability can be integrated into a process that uses automated Eddy Current or Ultrasonic test methods, frequently requiring only initial setup by the process machine operator.

Internal quality testing

The second issue is internal quality. This is now the most important quality feature and anyone attempting to meet an inspection requirement should seriously consider the economics and desirability of adding some internal 100 percent volumetric testing capability. Internal control has historically been accomplished through some selective destructive metallographic monitoring to check overall billet or bar quality by examining the size, count and structure of inclusions and the centerline condition. This process, however, cannot achieve the current 100 percent volumetric testing requirement that is specified for many mission critical applications such as components for aircraft/aerospace, wells, heat exchangers and other mechanical uses. The potential financial loss associated with a quality failure now is so staggering that no company can afford to take the risk of supplying, purchasing or using product of unproven quality in any critical application.

The NDT test method & system

The next step is to choose the most appropriate test method and system. These systems can be for testing billets, long solids of various shapes, or tubes in varying conditions. Bar or tube testing systems can be installed into a production cell or one can use a stand-alone flexible test system that is designed to handle a range of testing requirements. Many specialized systems require highly qualified operators and supervisory personnel and can require accreditation by customers or outside agencies such as Nadcap (National Aerospace and Defense Contractors Accreditation Program), TÜV Rheinland or ISO (International Organization for Standardization). Most serious buyers of quality bar stock or tubes will require the producer to have documentation covering a number of issues that impact the inspection process such as documentation of:

• A management system

• Test system with scan plans

• Personnel capability

• Capability to detect characteristic natural defects

• Testing procedures

• Calibration test standards

There are many possibilities relating to the configuration of the test equipment and the potential return on investment. Generally, the producer should try to maximize investment return by selecting a test system that allows entry into as many markets as possible.

Some specific decision parameters would include:

- Surface inspection only or volumetric internal inspection.

- Test speed or productivity requirements.

- Bars: Test level. Test level AAA, AA, A, B, C. As defined in MIL-STD-2154, AMSSTD-2154 and ASTM E 2375.

- Tube: Test level and method as dictated by Various ASTM, EN, ISO or API requirements.

- Customer dictated test level based on the particular application.

- Projected production yield.

- Size changeover time.

- Overall inspection productivity.

- Initial cost & costs of ownership.

Production philosophy

Many suppliers are now producing product in specialized cellular structures. These arrangements are situated to allow large volume production with minimal handling and delays in receiving stock for the particular production machine. This deceptively simple organization of production and finishing operations can result in very efficient production of some materials and can justify a relatively simple dedicated testing machine to inspect the finished product from this cell or part of the cell.

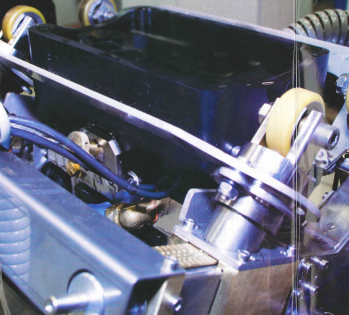

Another method is to simply install a very flexible, high throughput test machine that can be fed by several plant production centers. This type of machine requires heavy scheduling to allow the many various products to be tested or inspected just before they go out the door or before the final end finishing is done on the production material. Testing in this manner can and does justify a relatively high level of expense to minimize the set up times, and allows testing at the high throughput speed required to keep up with the plant capacity. Some testing machines can be changed over to a new size in five to 15 minutes and can test at two m/s with product butted together or with minimal gaps between pieces to maximize the equipment usage.

Stainless steel tube producers are agreeing to test product in as-welded, as-rolled and drawn condition. While the as-welded tube condition is the most economical to produce, it is also the most difficult to test because the weld heat affects the local grain structure, and the weld profile is only moderately controlled. A tube fabricator producing as-welded tube must thoroughly understand the weld process and use the NDT test information to modify the process, which will allow for a high quality level to be achieved.

These test units can be designed to test at the needed quality level and rate of a particular production cell. Some fully configured ultrasonic units, often located off line, contain 24 to 32 transducer elements and can test to extremely high quality Class AA levels. This level ensures three times detection of a particular notch or natural defect, at high testing speeds. Another configuration that has been used includes 24-6 to 8mm individual beams allowing very high testing velocity, which can reach approximately two m/s at class A levels.

For tube product, many Magnetic Analysis Corp. systems can test small tubes to OD and ID mandated notch detection requirements and can also include other NDT methods available from MAC. This can include simple longitudinal Ultrasonic OD and ID notch detection. Or, they can be fully configured for testing in five directions (CW, CCW, FWD Transverse, REV Transverse and Normal Incidence) to inspect for defects, lamination, wall thickness and OD/ID dimensions, with as many as 32 elements, all at 100 percent volumetric test. These systems feature fast change over and can be adjusted for a new size in five to 15 minutes. A common test speed is 0.75 to 2m/s. Oblique inspection directions can also be accommodated.

Maximizing product condition & presentation for accurate testing

Success in any testing application depends almost completely on the product’s dimensional uniformity and presentation stability through the test system. A premium must be placed on maximizing the product’s straightness, roundness and surface finish. These three parameters also influence the ultimate product quality in the eyes of most purchasers of long products.

In addition to the product condition, a review and careful selection of the intended conveying system configuration is critical. MAC has found that working closely with the customer to exchange accurate information about the way the material under test is going to be brought to and through the test system, results in greater equipment productivity, system repeatability, savings in installation time and improved overall satisfaction with the test system. For example, many systems can be designed to minimize the gaps between the product and, in many cases, this removes extreme speed testing requirements and allows for maximized repeatability. Very high accuracy conveyor inlet and outlet roll alignment and roll quality is absolutely required to eliminate vibration and achieve short and long term success.

Balancing costs & results

Almost any NDT system is a compromise between the absolute best available technology and something that makes good economic sense at the time. In selecting the best NDT system, producers may tend to focus primarily on the test equipment itself, without considering as carefully as they should the appropriateness and effectiveness of the mechanical configuration and conveyance design. Even if an optimal handling system is recommended by the NDT supplier the price may lead to a less expensive choice that “should be good enough.” But it is also possible that the quality or lack thereof of the mechanics surrounding a tester might cause higher reject rates that will ultimately cost much more than the initial cost differential. Additional considerations are down time due to maintenance requirements and size change set up time. In retrospect, a little more money spent up front may well be the best decision to economically meet existing requirements and also handle increasing quality demands in the future. So the question is how to choose the proper configuration for a particular need and leave a little flexibility for the future. Some producers MAC has worked with conference with all potential suppliers and discuss not only what they hope to achieve, but also what is actually possible, before finalizing their request for bid and specifications.

Conclusion

Ultimately, a wise decision will be based on experience and knowledge of various manufacturing and testing techniques and installations. Decisive factors are ones of productivity, quality and specific testing requirements. Some systems need a dual or multiple personality that can be adjusted and optimized to meet changing test requirements. Variable testing capability is driven by flexibility in the instrument and flexible transducer configuration and supply. The bottom line: An experienced NDT supplier can be a valuable resource for the producer in making these judgments.