STAINLESS STEEL WORLD-AMERICAS JUNE 2018

Nondestructive Testing (NDT) has been around for many years, but what we are seeing today is a swift growth in when it needs to be used. More and more makers of stainless steel products are finding they must insist on the highest quality possible raw stock for their production needs.

Producers of constant cross-section stainless products such as tube and bar stock must meet the increasingly tighter standards from ASTM, API, ASME, and similar organizations and satisfy the ultimate users, ranging from aerospace, nuclear, and automotive high-end applications to furniture and consumer goods manufacturers. In many cases, it’s not just a matter of rejecting product that fails the inspection; it is also important for the producer to have continuous feedback from NDT testing to make corrective adjustments in their production process.

What follows is a discussion of what and how tube and bar are being inspected with NDT to meet these requirements.

By Joseph Baldauff, Vice President – Technology, Magnetic Analysis Corp

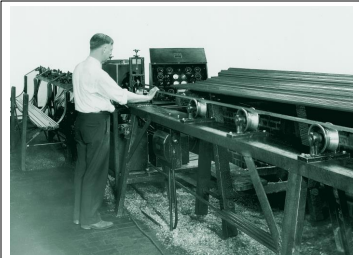

Eddy current encircling test coil inspecting welded stainless steel tube.

NDT Test Systems

Stainless tubes and bars are made from expensive material. The bar and tube users expect to receive the highest quality material. Indeed, some bar and tube manufacturers enjoy a preferred market position because of their deserved quality reputation and documented ability to meet the tightest quality requirements.

NDT systems come in many different configurations and forms. Some are more costly than others, but low cost is not always the best choice. Each NDT supplier has a unique approach. Choosing an NDT supplier/configuration is almost like picking a mate for marriage—there are pros and cons to every partner and system. Some are more expensive, and while they can pay off, that is not always the case.

NDT inspection, while moderately priced, adds little to the final product cost if the system is reliable and can operate at the needed production rates without bottlenecks or negative impacts (false rejections) on the product scrap rate.

Eddy Current Hot Probe inspecting the weld zone of a stainless steel tube immediately following the weld head

Characteristics of an NDT System

Demonstrated Capability

The NDT system must reliably detect any condition that could cause failure in a critical final device, such as airbag components, brake components, fuel injectors, pressure vessels, and transmission components. It is the bar/tube manufacturer’s responsibility to ensure defect types that could lead to failure are detected. This makes good business sense and is sometimes the only way certain users will purchase their product.

Demonstrated Repeatability

NDT systems are configured to optimize repeatability for ASTM-mandated notches and holes, which are specified by the NDT purchaser. The obtainable repeatability is a strong indicator of the system’s quality and impacts testing velocity and inspection quality level.

System Availability

Most test systems are designed to keep up with plant or cell production rates. However, system availability can impact production if service, calibration, or maintenance is needed. A high-quality drive system and a low-maintenance testing head are essential to ensure maximum reliability and zero downtime. The best NDT systems require little to no maintenance.

NDT System Support

Some systems may have a low initial cost, but their suppliers may struggle to provide quick support. Bar/tube manufacturers often need immediate attention to application problems. A good NDT supplier should have a well-trained field group that is knowledgeable about industry inspection norms and available on short notice.

Changeover Time

A good NDT test system must be able to switch to a new product size quickly. Extended changeover times can be considered downtime if they exceed the changeover time of the bar/tube processing cell or material handling system.

Signal-to-Noise Ratio

A high-quality system should allow for a signal-to-noise ratio of at least 4:1, with higher being preferable. The obtainable ratio depends on the NDT configuration, material quality, straightness, surface finish, grain size, and melt quality.

Test Technology

Tubes

Stainless tubes ranging from <0.1 inches to 40 inches in diameter can be tested at the point of manufacture using NDT technologies such as Eddy-Current (EC) and Ultrasonic.

Eddy-Current (EC) – Weld Mill Application

Tubes can be tested in semi-finished and finished form. At the point of manufacture, tubes can be inspected directly beyond the weld head on the weld mill to provide immediate quality feedback to the weld operator. This feedback can enhance the welding process by detecting slag buildup on the weld electrode, which may not immediately impact the weld but serves as an early warning of potential issues. More serious defects, such as incomplete welds, cold welds, penetrators, and off-center welds, can also be detected.

Off-Line Eddy-Current (EC) Inspection

Most tubing products are sold under ASTM or other mandated quality/inspection requirements. In some cases, an encircling eddy-current inspection coil can perform "full-body" inspection on the mill to fulfill these requirements. However, material on the mill is still in a semi-finished state. The highest quality is typically achieved after additional processing, such as final batch heat treating, straightening, and end finishing.

For this reason, the most rigorous inspection using NDT methods is usually conducted at an off-line inspection station. These off-line testing stations are designed for optimal centering and vibration control, using conveyor mechanisms that stabilize the product during transport stability.

Stainless tubes are generally considered nonmagnetic therefore they can be directly tested without consideration of magnetic permeability suppression. While this is true for some grades of stainless, other grades will demonstrate some permeability variations. Some slight pickup of magnetic material on the product surface – one steel wool hair for instance can cause a false rejection. For this reason, most eddy current encircling coil testing is done with use of some DC magnetic field to suppress these permeability variations. This saturation should be done with as small a gradient field as possible. One consumer goods application that can require some NDT inspection is vacuum drink containers. Some high-quality drink container manufacturers now require high-quality thin wall tubes as incoming raw materials. Some suppliers are now using EC NDT to assure the material quality.

Automotive products suppliers are now required by the automotive companies to supply devices with their quality measured in parts per million. This is achieved in part by fairly high degrees of NDT testing of the tubes and bars that are purchased by the automotive parts manufacturers. These include air bag propellant components, fuel injector components, corrosion-resistant brake parts, including brake hydraulic lines, automotive fuel line assemblies, car exhaust tube components, engine valves, and many more. The majority of these parts are made from bar and tube product that has been tested with some NDT full body inspection method.

An Ultrasonic test (UT) on titanium

Ultrasonic testing method (UT)

Materials for the higher, more critical uses are now required to be tested with the Ultrasonic method. This method of product testing is generally complementary to the Eddy Current method. The Ultrasonic method is very capable of detecting defects in heavy wall tubes. It can be used to measure the tube’s full dimensional characteristics including wall thickness, ID (Inside Diameter Defects), OD (Outside Diameter Defects), Ovality, Eccentricity, etc. Ultrasonic methods can detect defects in many different orientations. Ultrasonic inspection may be mandated by the material buyer. It may be specified to conform to ASTM E217 or other norms.

Stainless bars are tested with Ultrasonic methods and can be conducted in up to five directions. The simplest is bar internal quality. This method is limited to the bar internal area but is blind to surface (seams and laps) and sub surface defects (inclusions). This blind area is like an outer onion layer of 2 to 3 mm thickness.

Bars can also be tested with shear method – clockwise and counter clockwise. This allows the bar surface and near surface to be tested and because the sound beam is originated from the inside of the bar, sealed seams can be easily detected. This is a very sensitive test method and it can detect seams and laps that are very shallow. This method allows the inspection to be adjusted to any seam depth. Typical allowable seam depth could be anywhere between 0.002” to 1% of the bar diameter depending on the end-use and the final material finishing method. Two additional directions can be implemented. These are transverse forward and transverse reverse. This direction can detect transverse cracks and internal cupping. Only a small percentage of bars are tested using the transverse method.

Ultrasonic testing is normally done on a totally finished stainless tube or bar. The test method can be applied to a spinning stationary tube or bar, helical traveling spinning tube/bar or to a conveyed tube/bar that passes through the center of a rotary spinning transducer configuration or Phased Array (PA), spinning sound beam device. The spinning tube is generally limited to 3’(min)/second circumferential speed.

The rotating transducer rotary or PA can rotate at much higher speeds than the spinning probe test method due to higher coupling water pressure. Rotary devices can achieve the highest inspection throughput. Multiple element arrays can also be used to achieve highest inspection rates in rotary test devices. Phased Array devices can also be used that rotate the sound by use of multiplexed transducer arrays that cover the entire product circumference.

An Ultrasonic inspection system testing stainless steel heat exchanger tube.

Volumetric testing, repeatability, signal to noise ratio and other considerations

In order to properly test raw stock, it is generally accepted that the entire product volume needs to be tested. This assures that small detrimental defects are detected and eliminated from the raw stock supply. The detection of the smaller defects must be assured but this should not be achieved at the expense of the NDT system noise level. A high noise level system will cause unacceptable false rejections of good product. For this reason, the system signal to noise level is generally a parameter that is critical.

To assist in achieving good signal to noise ratio, short transducer beams are used but this causes the test speed to be reduced. Multiple element arrays can help to increase the testing speed by application of more channels in each direction.

Multi Element Ultrasonic Transducer test head for Echomac 75mm rotary immersion type coupling.

Ultrasonic Weld Zone Tester uses water irrigated transducer shoes that ride the surface of the tube. The test head can shift forward to test the calibration tube shown in the foreground.

Ultrasonic phased array in bar testing

The newest development in bar testing is using phased array technology. This is a reliable method to obtain three-direction testing. The Phased Array method uses a transducer made from a multitude of small single element devices (64, 128, or 256) to make one of six to eight transducers that encircle the product. This is the needed configuration to allow spinning the sound around a non-rotating conveyed bar. The requirement to test the full bar volume – internal - NI and CW and CCW shear does force the arrays to test in sequential mode. This time-shared transducer device then becomes speed limited if the user or final customer demands repeatability on the mandated flat bottomed drilled holes and notches. If repeatability cannot be obtained at production speed then it is not possible to claim that volumetric testing is being done on the product.

Some rotary devices can operate at up to 400 ft. per minute (2m/s) and still obtain repeatability on all notches and flat bottomed drilled holes and obtain an honest volumetric test.

NDT – An important tool for quality

NDT is a tool that requires care and understanding of the technology and its application during production. For critical applications, it is absolutely essential and for less critical ones, it is still important for optimizing the production quality.

Proper NDT must be ensured to satisfy growing customer expectation and quality demand.

Magnetic Analysis Test system using Ultrasonic and Eddy Current Technology to inspect tube 40-180mm diameter.