Detecting Welds with MAC®: Tubes, Pipes, and Wire

Weld defects are present in the manufacturing of tubes, pipes, and wires. They can compromise structural integrity, lead to costly failures and harm a producers’ quality reputation. Testing for the detection of these welds is paramount in the production process. Manufacturers know this. The only true question that should be asked is how? Magnetic Analysis Corp has been helping mills answer this question for 95+ years, designing solutions that detect a wide range of discontinuities and ensure compliance with rigorous industry standards. The below information dives into the various solutions MAC® offers for weld detection that can be implemented in your mill.

The Echomac® PA Tube Weld Tester employs Phased Array Ultrasonic Testing (PAUT) to perform high-resolution inspections of Electric Resistance Welded (ERW) tubes. PAUT technology allows for electronic beam steering and focusing, eliminating the need for mechanical adjustments when the weld remains within the system’s specified radial position. The system effectively identifies ID/OD longitudinal flaws, lack of fusion, porosity, and other discontinuities caused by the welding and scarfing process.

Technical Advantages:

- Ensures full volumetric coverage without mechanical probe movement, providing consistent and repeatable results.

- Real-time B-scan and C-scan imaging allow for detailed weld profile visualization and rapid defect assessment.

- Automated adjustments through the Human-Machine Interface (HMI) enable minimal operator intervention, increasing efficiency.

- Capable of detecting defects such as N10 and N5 notches, 3.2mm through drilled holes, and half-wall drilled holes with superior sensitivity.

For comprehensive full-body ultrasonic inspection, MAC's Echomac® Full Body Tester utilizes an Adaptive Pitch Control (APC) transducer carrier and precision "Spin-The-Tube" conveyor to inspect materials with exceptional accuracy. This system provides in-depth evaluation of both welded ( and seamless) tubes, ensuring conformance to ASTM and API standards.

Key Features:

- Enables precise helical scanning by dynamically adjusting transducer angles in real time.

- Detects longitudinal, transverse, and oblique defects, as well as wall thickness variations and laminations.

- Accommodates ovality and slight straightness deviations without compromising test accuracy.

- One-knob roll separation adjustment allows rapid adaptation to different diameters.

- Multiple ultrasonic transducer arrays ensure high-speed, high-fidelity signal processing for defect characterization.

For high-speed inspection of round bars and tubular products, Echomac® Ultrasonic Rotaries provide industry-leading precision and versatility. These rotary units support welded (and seamless) tube inspection across a broad diameter range, 5mm to 500mm, and are designed to meet API 5CT and 5L standards.

System Capabilities:

- Supports 100% volumetric coverage at production rates exceeding 8,000 RPM.

- Optimized for superior signal-to-noise ratio, reducing false positives and improving defect resolution.

- Maintains consistent water column integrity, ensuring uniform ultrasonic energy transmission and test results.

- Enables concurrent CW, CCW, FWD, and REV scanning, enhancing flaw detection in all orientations.

- Minimizes maintenance needs and enhances durability in high-contamination mill environments with seal-less rotary design.

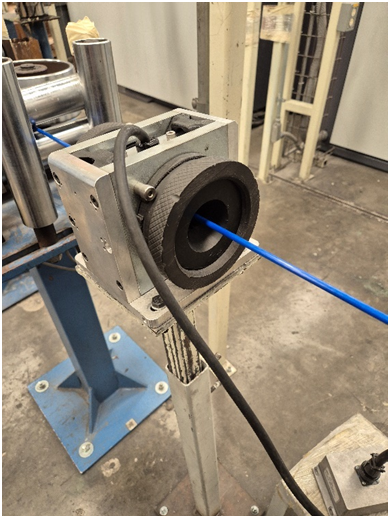

For surface and near-surface defect detection, Minimac® II utilizes eddy current technology to perform high-speed inspections of tubes, bars, and wires. This system excels at detecting laps, slivers, cracks, and weld line faults in both magnetic and non-magnetic materials.

Technical Specifications:

- Capable of testing at speeds up to 4000 f.p.m., with optional configurations for even higher speeds using wide-spaced coils.

- Simultaneous flaw and absolute testing improve defect identification accuracy.

- Supports single- or dual-channel rotary probe configurations for enhanced longitudinal flaw characterization.

- It can be easily integrated into existing NDT lines, with real-time feedback for process control.

- Advanced digital signal processing algorithms ensure precise defect classification and minimal false indications.

MAC's advanced NDT technologies provide precision and reliability for weld integrity assessment in industrial manufacturing. By integrating these cutting-edge ultrasonic and eddy current testing solutions, manufacturers can enhance quality control, reduce scrap rates, and ensure compliance with industry specifications. Engineers and quality assurance professionals seeking the highest level of defect detection and material evaluation will find MAC's solutions indispensable for optimizing production efficiency and maintaining structural integrity in welded components.