A LEADER IN NONDESTRUCTIVE TESTING SINCE 1928

Magnetic Analysis Corporation has been advancing the science and technology behind nondestructive testing for over 90 years. On the world stage, MAC® is recognized as a major resource for eddy current, electromagnetic, flux leakage and ultrasonic inspection systems for testing metals.

MAC Elmsford, NY Headquarters

MAC Today:

- Three impressive, state of the art facilities form the backbone of our company: MAC’s ISO 9001-2015 certified manufacturing and engineering facility in Elmsford, New York; a manufacturing and ISO/IEC 17025:2017 laboratory certified plant in Boardman, Ohio; and Magnetic Analysis Nordic’s manufacturing plant in Östersund, Sweden.

- Our products and testing instruments are used in countless countries and territories, in plants and mills where wire, tubing, bars and metal parts roll through automatic inspection systems without missing a beat.

- In addition, MAC’s global network of field engineers and experienced representatives are always available to locally supply custom services, installation, routine maintenance, or repairs. This support staff gives MAC the unique ability to provide the highest level of personalized service, just about anywhere in the world.

- Maintenance service can be provided for most systems by a service contract, or on a per call basis.

- Our testers and services are also offered through MAC’s unique leasing program, which includes both equipment and service in one package.

MAC Milestones:

- 1928 Magnetic Analysis Corp. is founded in Long Island City, NY, by William Gould and William Gould Jr.

At that time, most testing inspection involved “sampling” techniques that essentially destroyed part of the product in the process. An evaluation method that would permit products to be used after testing proved to be a very attractive and successful idea and, as a result, a group of patents was developed for nondestructive testing of steel bars. Translating this NDT concept into a viable tester took six years of research and development.

- 1934 MAC introduces the first successful nondestructive tester to identify cracks in steel bars.

1st MAC NDT equipment installed at a customer’s plant

- The 1930’s-1940’s The use of NDT expands in the U.S. steel industry, spurred by demands for ordnance testing in World War II.

- 1953 MAC introduces the first commercial eddy current tester in the U.S., a major advancement in NDT technology.

MAC equipment featured in 06/03/1940 issue of Time magazine ad for J & L Steel

- 1959 MAC launches Rotomac®, the world’s first spinning probe eddy current tester.

- 1964 MAC opens its plant in Mt. Vernon, NY, gets a new president, and continues to expand operations.

MAC ERIC III EC Tester, Circa 1960

- 1968 MAC introduces the first eddy current tester with phase gating and filtering.

- The 1970’s MAC broadens its flux leakage product line.

During this decade, MAC developed flux leakage detectors for military ordnance parts applications and for tube and pipe inspections, including OCTG.

- 1989 MAC develops its own line of ultrasonic rotary testers.

- 1992 MAC launches a fully computerized eddy current tester, a new benchmark for the industry.

With its real-time, full-color graphic display, sophisticated control of test parameters and digital processing of test signals, this instrument brought eddy current testing to a whole new level of precision and sophistication.

- 2010 MAC relocates operations to a larger plant in Elmsford, NY.

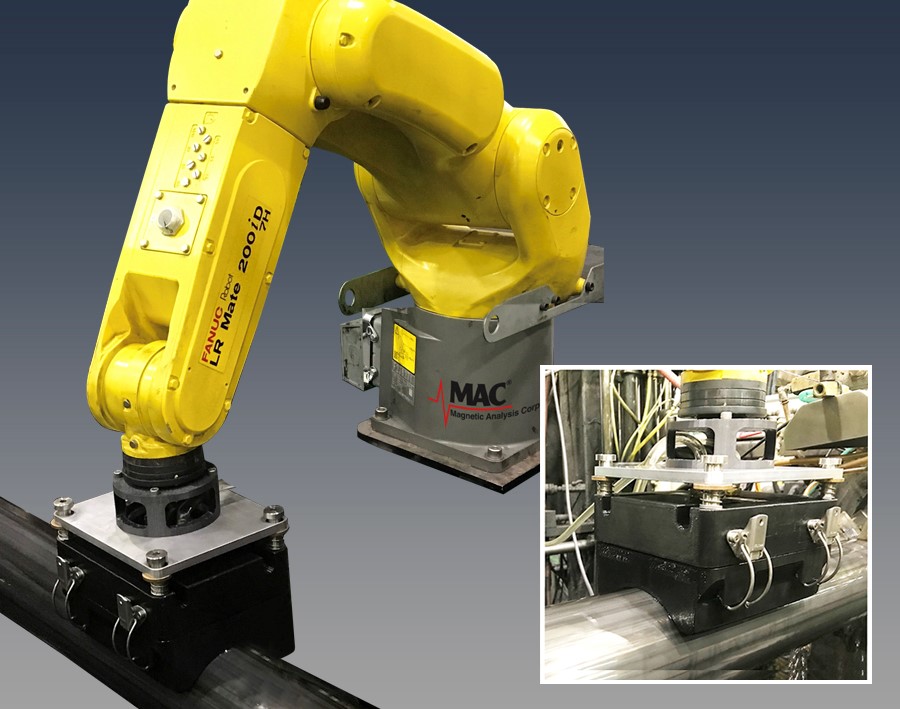

MAC Rotomac® Tester with 350 Rotary Mechanism, featured on cover of Quality Magazine, April, 1991

- 2016 Dudley Boden appointed MAC President & CEO.

Under the leadership of President Boden, the company broadened its technology and testing applications and took on a renewed sense of commitment to 100% customer satisfaction, using our years of experience in metal manufacturing plants to partner with the customer, learn what their real needs are, and develop the best test system for the specific application.

- 2018 MAC delivers new products at home and around the world.

- 2020 MAC Introduces Phased Array UT Systems for Welded Tube.

The year 2020 marked MAC’s entry into the field of phased array ultrasonic inspection systems for the welded tube market, with the introduction of the Echomac® PA TW System. These phased array systems offer advantages of minimal operator adjustment, wider test head coverage of the weld zone, and the ability to monitor in the hot zone to provide immediate feedback to the operator. Welding and seam trim tool process errors can be quickly addressed, resulting in less scrap tube. The systems can also detect gross flaws when located in the hot zone or conduct more precise flaw detection after the forming rolls when the tube has a finalized round shape. Phased Array systems are also available for other applications, including testing bar, composites and rail wheels.

- 2023 Daniel Lawrence is appointed MAC President & CEO.

On November 6th, MAC announced the appointment of Daniel Lawrence as President and Chief Executive Officer. Just the fifth leader in MAC’s 95+ year history, Dan has succeeded former President/CEO Dudley Boden who provided steady and strong leadership during his 22 years with the company. Dan brings an extensive background in industrial and business management. Under his leadership, as MAC approaches its 100th year, the company is focused on bringing innovative NDT solutions to our customer’s most challenging problems, all while collaborating to meet the ever-increasing performance specifications and productivity requirements of today’s markets.

- Today A global leader in NDT technology.

As the only worldwide supplier of 4 key NDT technologies, MAC’s strength is integrating complete systems that incorporate multiple test modalities, materials handling, and remote access customer support, all under one user interface. With installed systems in over 30 countries, MAC works closely with metal manufacturers to provide systems or individual instruments that maximize their productivity while meeting market requirements and accurately identifying deficient product that does not meet their criteria. Our Business Development Managers, Field Engineers and Representatives, who collectively bring decades of experience and technical knowledge, can provide customers with preparation, installation, startup, operator training, follow up maintenance service and calibrations to ensure superior results.

Echomac® PA UT Tube Weld Tester

Dan Lawrence, President & CEO