MAC TO EXHIBIT AT TUBE DÜSSELDORF 2024

Monday, April 15 – Friday, April 19

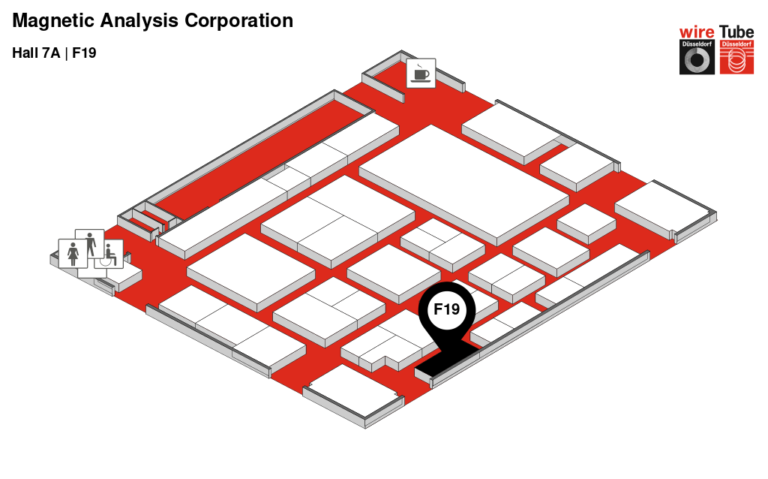

Stand F19 Hall 7A

Minimac® II Eddy Current Electronics

Visitors to Magnetic Analysis Corp. Stand F-19 in Hall 7A will see demonstrations of Minimac® II, the newest addition to MAC’s range of eddy current test instruments for detecting surface and sub-surface defects such as laps, slivers, cracks and weld zone flaws in non-ferrous and ferrous tube. Minimac® II’s compact design and versatility lends itself well to being used in a broad range of applications for tube producers and fabricators, on or offline.

The fully digital Minimac® II with its embedded processor, two test channel capability and MAC’s proprietary MultiMac® eddy current software offers high performance, accuracy, and reliability at an affordable cost. Applications include finding weld faults, such as short ID or OD defects as well as open welds in magnetic and non-magnetic grades. The instrument operates with encircling or sector test coils for detecting short surface defects, or rotary mechanisms with rotary spinning probe sensors for finding long, continuous flaws. Minimac® II can also detect ferrous inclusions in non-ferrous or austenitic grade products, including the popular 316, 304, and 254 stainless alloys. The operator friendly design ensures ease in setting sensitivity, phase, and filters on screen while viewing full color polar and linear display of real time, true waveform signals. Setups can be entered and monitored on site or through a computer network. Results and reports including location, time, amplitude, and phase information can be stored, annotated, and recalled from local or networked drives for an unlimited number of settings.

Also on display will be a demonstration Echomac® ultrasonic instrument for inspecting welded tube for incomplete seam welds and inclusions, voids or cavities.

MAC’s 95+ years of developing and supplying NDT equipment and systems to tube, bar, and wire manufacturers has given us a thorough understanding of customer inspection needs. MAC Engineers will be available at the booth to provide comprehensive information on the company’s full range of products, including standard and phased array ultrasonics, including upgrades for existing Rowa installations, the MultiMac® eddy current tester with up to 8 test channels, and Rotomac® eddy current rotaries for detecting long, continuous surface seams and custom automated mechanical handling test systems.