MEDICAL TUBE AND WIRE

Inspecting Critical Components for Medical Applications

As NDT techniques have expanded, so have the applications which now encompass many critical products that are being used where it is extremely difficult and expensive to replace or repair, or where failure can cause serious and life threatening consequences.

Wire and small diameter tubing used in medical applications such as stents, endoscopic tools, medical syringe needles and nitinol wires fall clearly into this category.

MAC has developed tests for these types of applications, using our MultiMac® eddy current equipment, which can detect surface defects in small diameter, very thin wall tubing, or wire.

MAC’s MultiMac® eddy current instrument used for these applications.

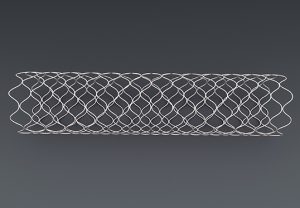

Testing small diameter tube used in stents

- Detect defects as small as 0.0006” deep in the ID of medical grade tubing with an OD in the range of 0.075” OD and a wall thickness of 0.004”.

- Used to make stents, the tube was made mostly out of L605 grade alloy.

- Specially tuned high frequency 3MHz encircling test coils were used.

- The 3MHz high frequency matches the electromagnetic skin depth of the test to the tube wall thickness, and allows the instrument to discriminate between flaws with depth and ”noise” from the tube’s movement, by using MultiMac’s phase shift electronics setting.

Testing small diameter tube for endoscopic tools

- Detect defects in 0.020” diameter, 0.003” wall thickness, 304L alloy tubing to be used to handle high pressure saline solution in a catheter shaft.

- High frequency 3MHz eddy current test coils are used.

Testing small diameter tube for medical syringe needles

- Detect very small ID/OD surface dents, cracks and pits in small diameter 304 stainless steel tube ranging from 0.26mm to 1mm diameter with wall thickness of 0.01”

- 3MHz ceramic bobbin coil focuses on the outer layers of the very thin wall tube to detect surface defects.

- Ceramic bobbin coils can prevent marking the tube, an important consideration for this product.

Testing Nitinol Wire for Cracks and Inclusions

- Test Nitinol shape memory alloy used in medical applications

- Uses XWN-.081 XSB Lemo extra small body Wiretester coil (test coils as small as .013″ ID are available)

- Detect cracks and inclusions that are typical problems that can form from the melting process during nitinol wire production.

- MultiMac’s phase sector output gate allows separate counts for cracks and inclusions, while rejecting only the wire with cracks.

MULTIMAC®

Eddy Current Instrument for Testing Tube, Bar, & Wire

- Operates with encircling, sector, or rotary test sensors.

- Up to eight test channels, null or absolute, can be used in any combination.

- Detect short surface and some subsurface defects in tube, bar, and wire.

- Inspect welded tube for short ID or OD defects in the weld zone.

EDDY CURRENT TECHNOLOGY IN NDT

MAC’s® Eddy Current Testing (ECT) systems incorporate computer-based test instruments and test coils that use two ECT coil technologies: encircling and sector coils, and spinning or rotary probe coils.

- Encircling and sector Eddy Current coil tests perform in this manner:

- The product is passed through or adjacent to an electrical test coil, which

has been excited by an alternating current. - This induces a flow of eddy currents around the test material or in the

case of a sector coil, in the area under the coil. - Short, intermittent anomalies or flaws cause a variation in the eddy current pattern, which the instrument detects.