MAC’s ECHOMAC® FD-6A AND TACTIC® UT IMMERSION SYSTEM FOR CRITICAL APPLICATIONS

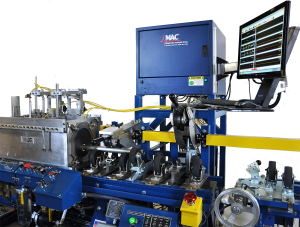

A test system supplied to a producer of titanium tubes for nuclear applications incorporates MAC’s (Magnetic Analysis Corp.) Echomac® FD-6A ultrasonic instrumentation with a TacTic® ultrasonic transducer immersion tank, mechanical handling, controls, and “spin the tube” conveyors, to provide a complete turn-key installation.

For this critical application, the ultrasonic test is conducted directly after the drawing operation to verify the tube meets the required specifications, before more pieces are run. The Echomac® uses 4 test channels to verify the OD, ID dimensions, eccentricity and ovality conditions, and 2 channels for flaw detection. Tube sizes range from 1/4” to 3” diameter. The immersion tank containing the transducers feeds directly to the FD-6A. The conveyor system consists of a 16’ inlet and 16’ outlet. Tactic’s rollers maintain the correct helix as the tube is fed through the tester, a critical part of ensuring accuracy during the test.

The Echomac® FD-6A, Magnetic Analysis Corp’s UT instrument, achieves a new level of improved signal to noise ratio, finer adjustments, improved thickness resolution, repeatability, and reliability. Featuring MAC’s user friendly Echohunter® interface software and versatile intuitive operation, control of all key test parameters is on a single screen, and thresholds can be moved by selecting and dragging on screen. A “Global” key allows parameters for several test channels to be adjusted at once, or copied from one channel to another. The 6A model has also received GE qualification for P3TF31, Class A & B, & P29TF82 Class A & B, a typical requirement for nuclear and aerospace applications. New installations or older ones that need to be upgraded can benefit from use of the Echomac® FD-6A instrumentation.

Magnetic Analysis Corp. based in Elmsford, NY and Östersund, Sweden, is celebrating over 95 years of providing NDT systems to the metals industry, including ultrasonic, eddy current and flux leakage test systems. The acquisition of TacTic® by MAC in 2022 broadened MAC’s range of NDT systems to include automated and specialized immersion, “spin the tube” ultrasonic test systems to detect surface and subsurface defects in round tube, pipe, and bar. These systems are especially applicable to metal producers who are looking for a cost-effective system to test small batches of material or frequent diameter size changes.

Ultrasonic Test System for Titanium Tube – TacTic® UT immersion tank containing the transducers which feed directly to the FD-6A is at lower left. MAC ‘s Echomac® FD-6A is at center.